Seeding disc structure assembly and seeding device

A technology of structural components and seeding devices, which is applied to the parts of seeders, sowing, and planting methods, can solve the problems of damage rate of damaged seeds, increased cost of mechanized equipment, and inability to adjust, so as to facilitate membrane breaking and drilling, and save The effect of human and material resources and smooth path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

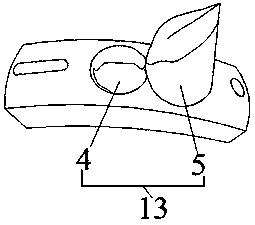

[0046] Such as figure 1 As shown, a kind of sowing disc structure assembly includes an outer sowing disc 1, a fixed disc 2 and an inner sowing disc 3, and the outer sowing disc 1, the fixed disc 2 and the inner sowing disc 3 have shaft holes on the same axis, and the inner sowing disc 1 The fixed disk 2 is embedded, the inner broadcast disk 3 is placed in the fixed disk 2, the upper end of the inner broadcast disk 3 is provided with a cover plate 7 and the cover plate 7 is placed on the fixed disk 2 and fixedly connected with the fixed disk 2, and the outer broadcast disk 1 The outside includes multiple groups of presser foot units 13 made up of leaking seed holes 4 and punchers 5 that are next to the leaking seed holes 4. Between two presser foot units 13, screws are inserted into the screws that are arranged on the presser foot units 13. Screw holes 15 are fixedly connected, and the shape of the presser foot unit 13 is arc-shaped both vertically and horizontally, and the tra...

Embodiment 2

[0049] Such as figure 2 As shown, embodiment 2 is a further improvement to the technical solution of embodiment 1. The slightly portion of the hole puncher 5 near the side of the seed leakage hole 4 is arc-shaped and pointed, which ensures that the shape of the hole is stable during the sowing operation, and the seeds enter the hole. The path is smooth, and the tip is arc-shaped and pointed, which is conducive to perforating the membrane. The arc-shaped point is close to the side of the seed leakage hole 4, which is beneficial to shorten the journey of seeds entering and facilitates the seeds to reach the ideal position of the hole. , build the microenvironment that is beneficial to seed germination, reach not only being beneficial to emergence, but also the requirement that emergence is not biased, all the other implementation modes are the same as embodiment 1, do not go into details here.

Embodiment 3

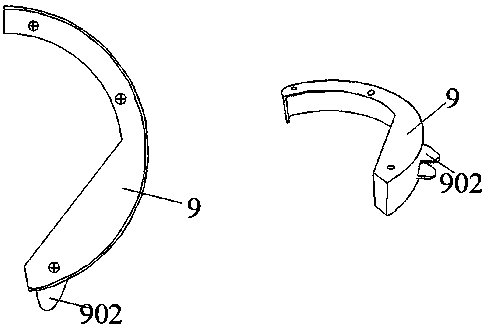

[0051] Such as image 3 As shown, embodiment 3 is a further improvement to the technical solution of embodiment 1. The inside of the inner sowing disc 3 is provided with a seed clearing device 9, and the clearing seed device 9 includes a guide piece 901. Matching, the outer side of the linear guide end of the lower end of the guide plate 901 is symmetrically provided with a single arc-shaped protrusion-902, and the single-arc-shaped protrusion-902 is placed in the seed hole-11 of the inner sowing disc 3. The benefit of this design is that the inner sowing disc The seeds in the seed hole-11 of 3 are cleaned out, and the guide piece 901 plays a seed guiding effect simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com