Rotor, electric machine containing said type of rotor, and method for producing a rotor

A rotor and rotor shaft technology, which is applied in the direction of engine control, manufacturing motor generators, electromechanical devices, etc., can solve problems such as broken metal wires of armature windings, and achieve the effect of reducing load and preventing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

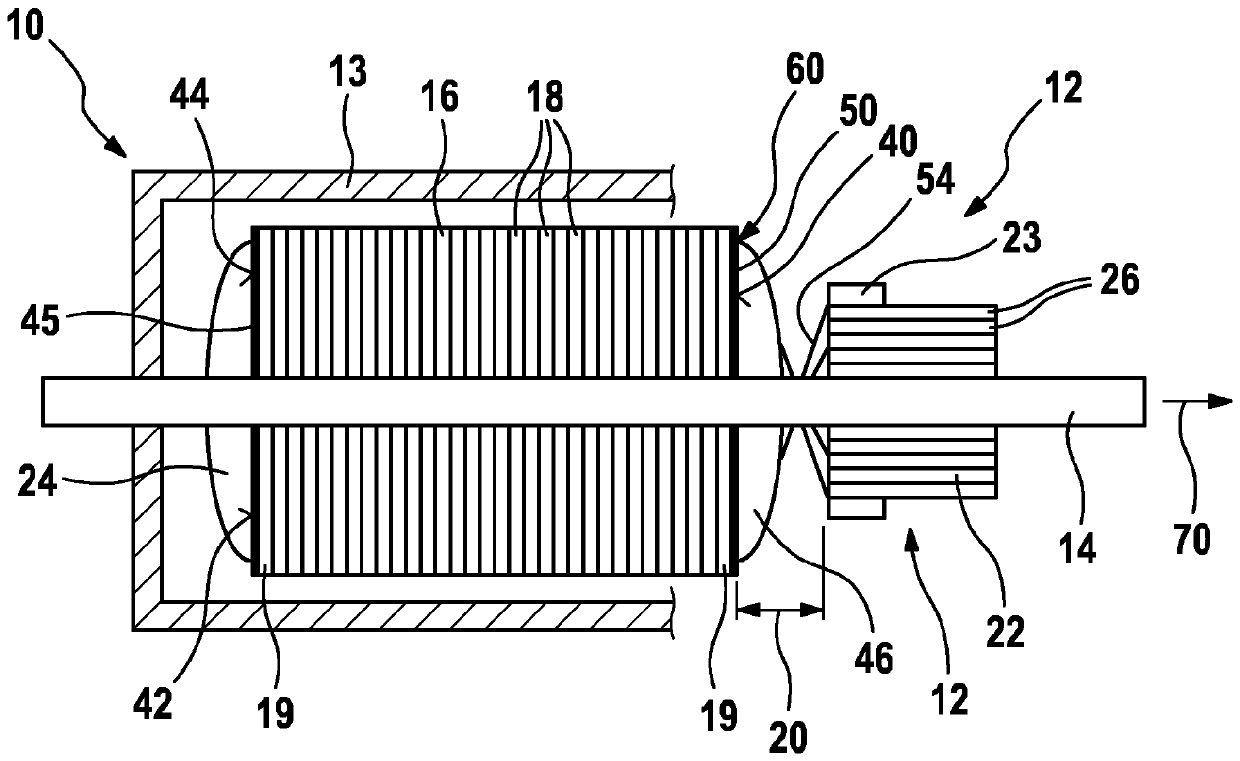

[0024] figure 1An electric machine 10 is shown schematically in FIG. 1 , wherein a rotor 12 is mounted in a stator 13 . The rotor 12 has a rotor shaft 14 , on which a rotor lamination stack 16 is fastened, which consists of individual magnetic steel lamination cores 18 , wherein the corresponding end laminations 19 First and second end faces 40 , 42 of the rotor lamination stack 16 are formed. The magnetic steel laminated core 18 is usually stamped from electrical steel sheets. The rotor core 16 is, for example, pressed against the rotor shaft 14 and fixed thereon in a rotationally fixed manner. A commutator 22 is attached to the rotor shaft 14 around an axial region 20 spaced apart from the rotor lamination core 16 . The commutator is likewise pressed against the rotor shaft 14 , for example in a rotationally fixed manner. An electrical winding 24 , which is electrically connected to a rectifier 22 , is arranged on the rotor core 16 . To this end, the rectifier 22 has re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com