Multi-section anchoring automatic yielding anchor rod and anchoring method

A technology of yielding bolts and anchoring, which is applied in the installation of bolts, earthwork drilling, mining equipment, etc. It can solve the problems of overall anchorage failure and deformation of the anchorage area of the anchorage, and achieve the prevention of anchoring agent failure, simple application and operation, The effect of preventing anchor failure or anchor rod breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

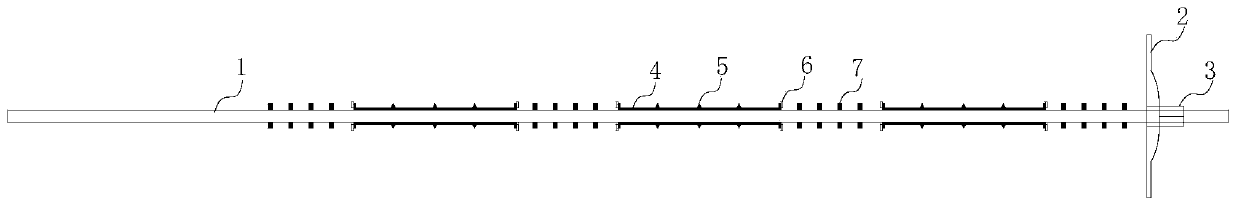

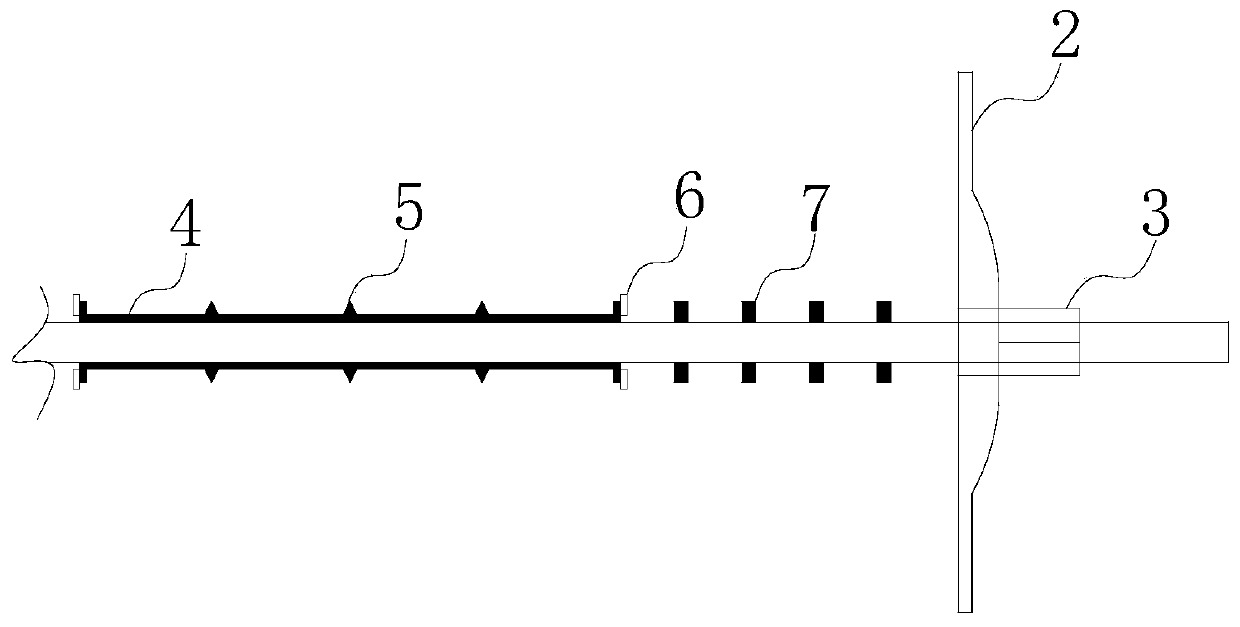

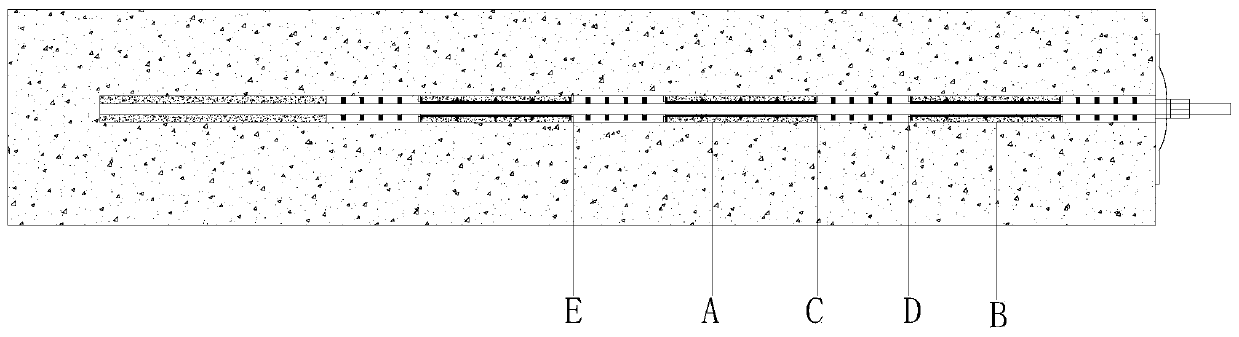

[0023] to combine Figure 1 to Figure 3 As shown, the present invention provides a multi-segment anchorage automatic yielding anchor rod and an anchoring method. The specific implementation is as follows.

[0024] The specific structure of a multi-stage anchoring automatic yielding anchor rod includes a rod body 1, a tray 2, a lock nut 3, a yielding sleeve 4, an annular tooth cutter 5, an annular rubber ring 6 and a yielding block 7, such as figure 1 shown. Set the pressure relief sleeve 4 and the pressure relief block 7 on the rod body 1 to achieve multi-section anchoring, and set the annular rubber ring 6 to prevent the eccentricity of the anchor rod during installation and the anchoring agent in the middle to flow into the free section. The annular tooth cutter 5 can The anchoring agent stirs quickly and strengthens the anchoring effect.

[0025] The anchor rod body 1 is welded with a pressure block 7, and the connection strength between the pressure block 7 and the rod b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com