Carton production machine using single paperboard

A technology for producing machinery and cardboard, which is applied in paper/cardboard containers, container manufacturing machinery, papermaking, etc., can solve problems such as production speed constraints, repetitive and boring, and high labor intensity, and achieve high production efficiency, stable and reliable work, and high application occasions. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

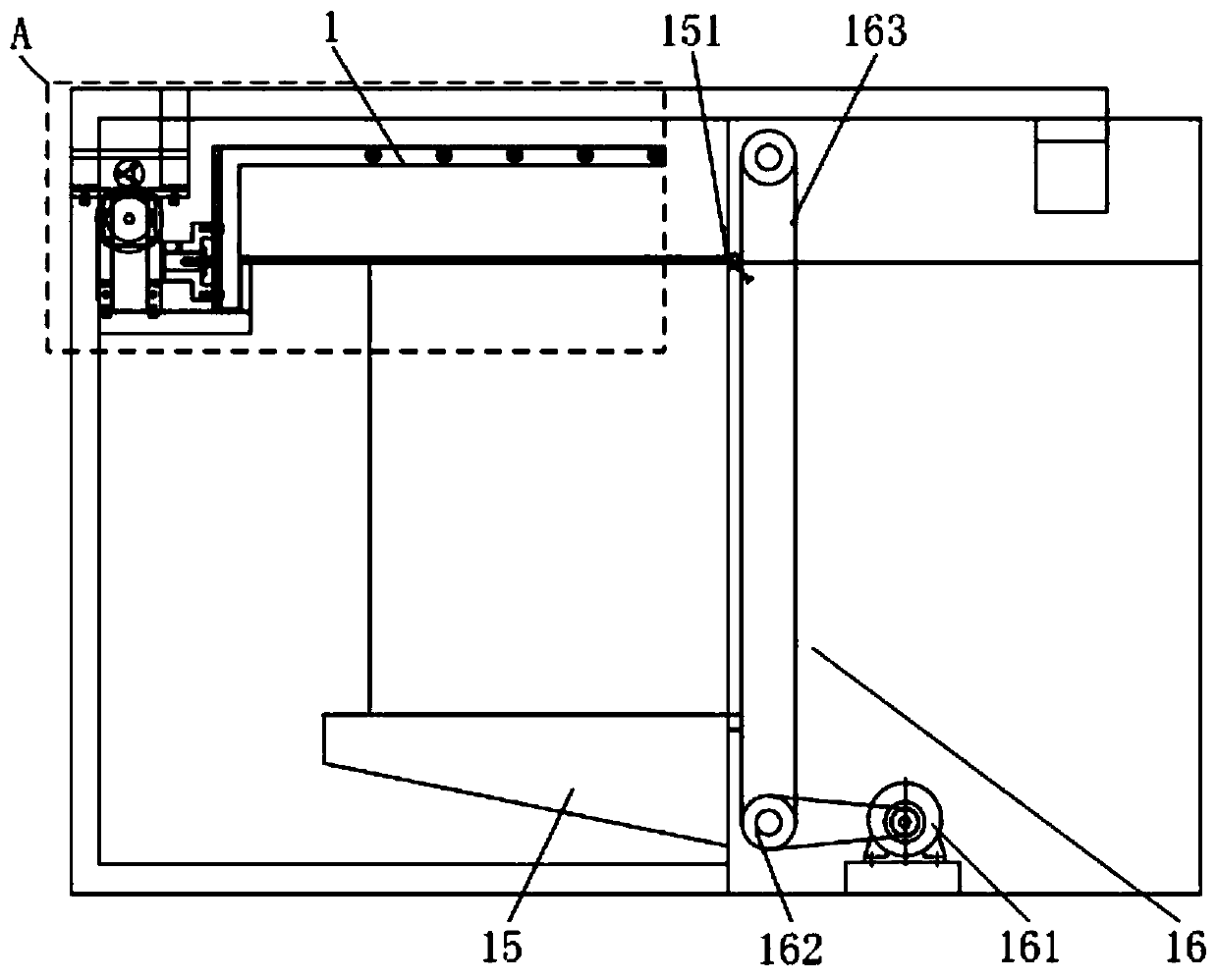

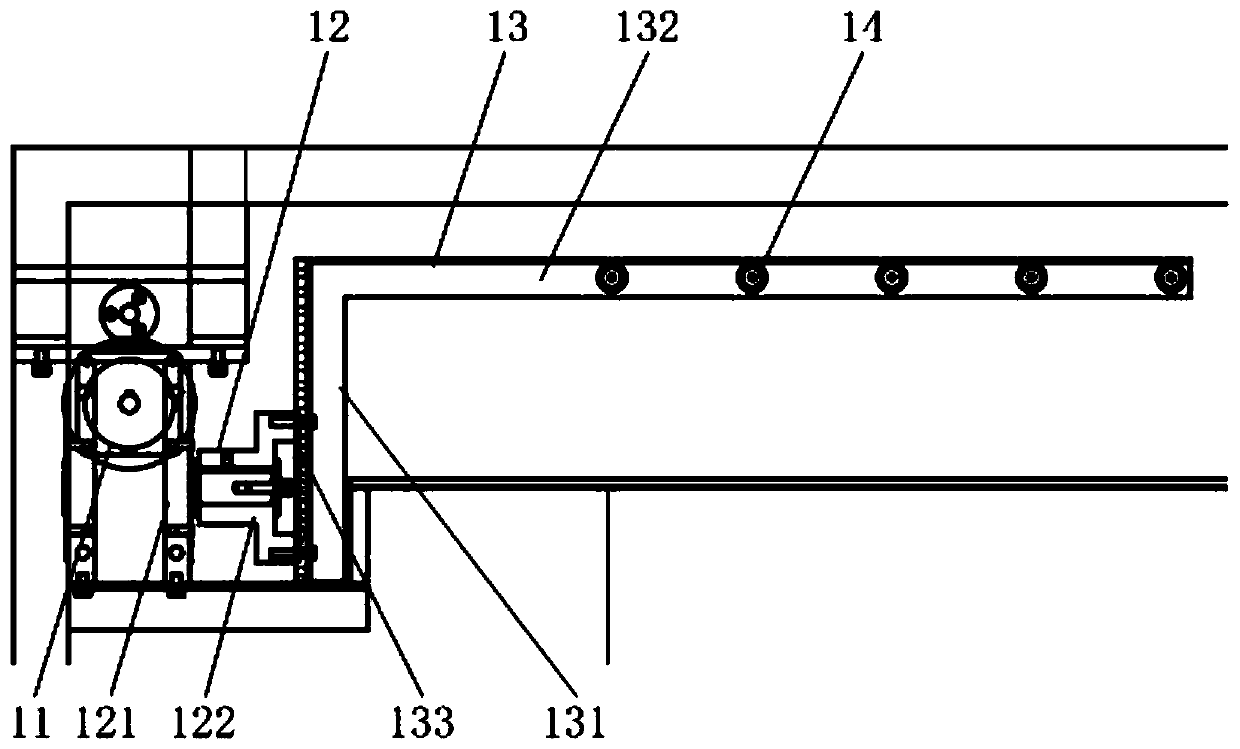

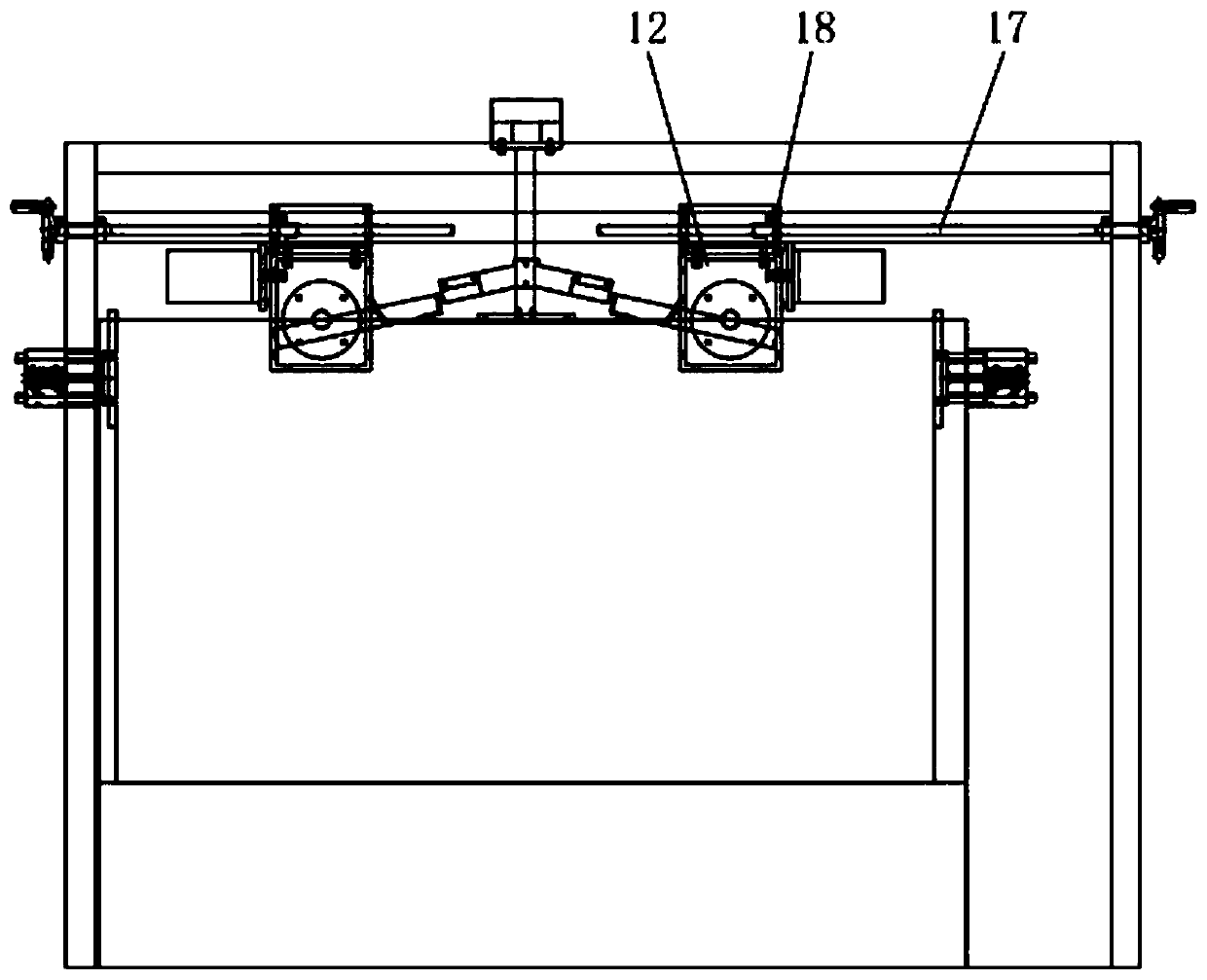

[0041]According to an embodiment of the drive mechanism 11 and the transmission mechanism 12 of the present invention, the drive mechanism 11 is a drive motor, the transmission mechanism 12 includes a reduction box 121 and a flange 122, and the drive motor and the input shaft of the reduction box 121 Connection, the flange 122 is connected with the output shaft of the reduction box 121; the swing rod 13 has a vertical part 131 and a horizontal part 132 connected with the vertical part 131; the flange 122 is connected with the vertical part 131.

[0042] Preferably, the vertical portion 131 is provided with connection holes 133 of different heights, and the height of the vertical portion 131 can be adjusted by selecting different connection holes 133 to connect with the flange 122 .

[0043] According to another embodiment of the drive mechanism 11 and the transmission mechanism 12 of the present invention (not shown in the figure), the drive mechanism 11 is a swing arm cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com