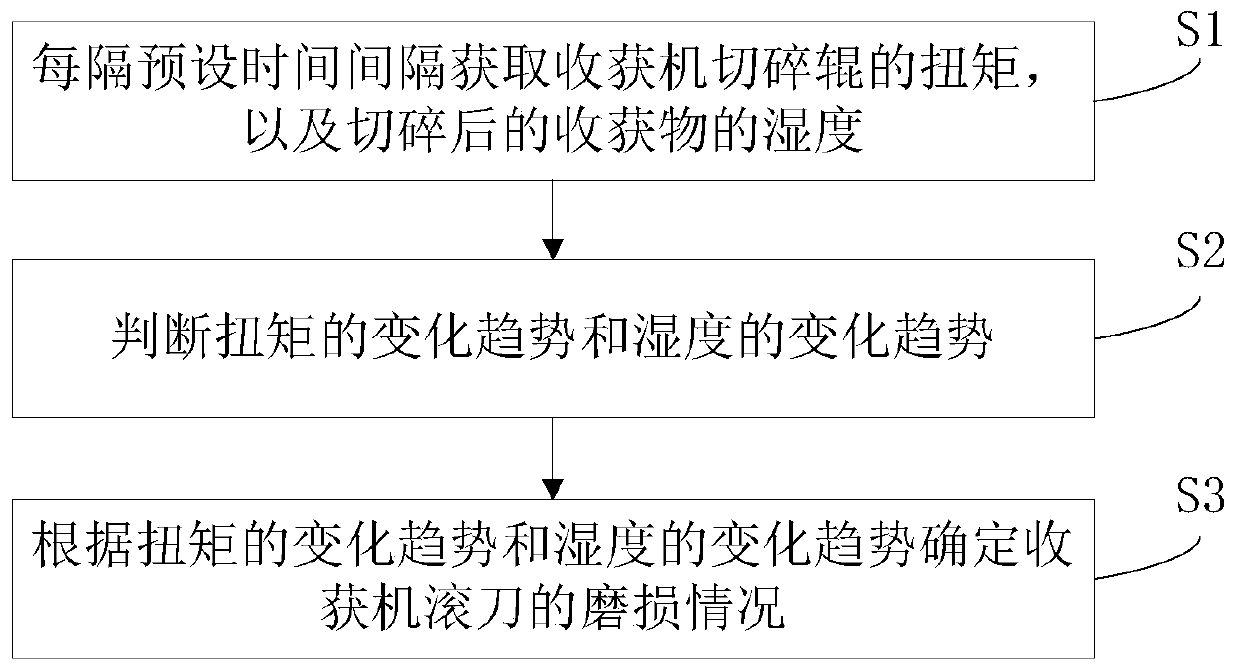

Method and device for judging hob wear conditions of harvester

A wear condition, harvester technology, applied in the direction of registering/instructing the work of the machine, instruments, registering/instructing, etc., can solve the problems of poor chopping quality, affecting the degree of fermentation, kneading silk, etc., to achieve high practicability and improve operation. The effect of high efficiency and high judgment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

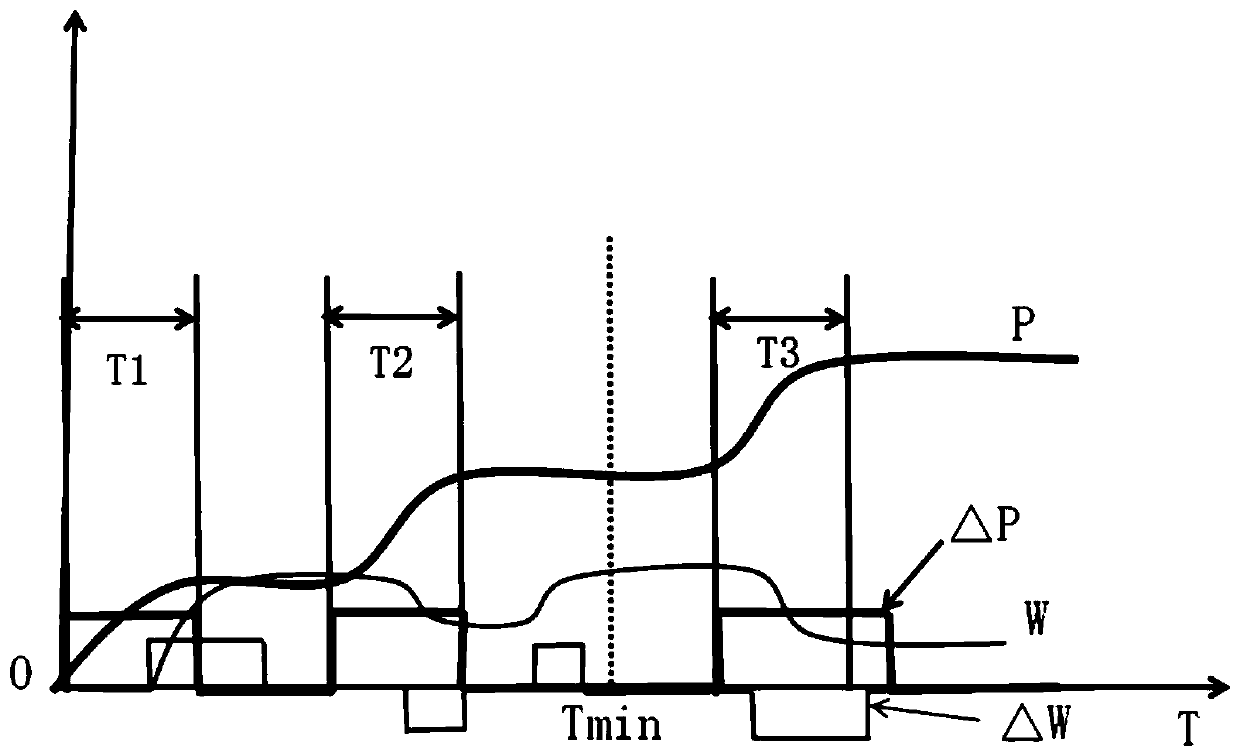

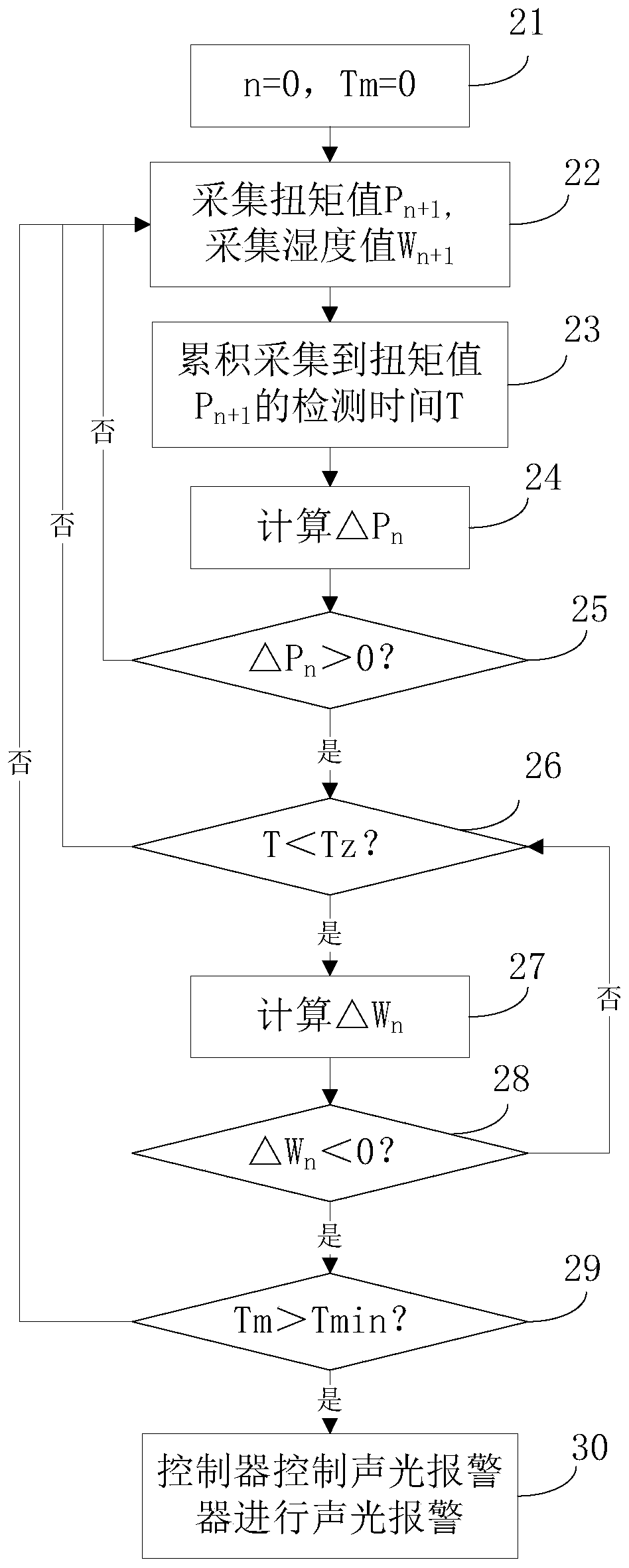

[0121] Such as image 3 As shown, the flow diagram provided for other embodiments of the method for judging the hob wear of the harvester according to the present invention provides a preferred implementation method, which includes:

[0122] Step 21, after the hob sharpening is completed, the controller initializes the parameters so that n=0, Tm=0, where n is the number of times the torque sensor collects the torque, or the number of times the humidity sensor collects the humidity, and Tm is the cumulative time of the controller hob usage time;

[0123] Step 22, after the torque sensor collects the torque of the chopping roller for the nth time, after the time interval ΔT P After collecting the torque value P n+1 , after the humidity sensor collects the humidity of the harvest for the nth time, after the time interval ΔT W Collect humidity value W n+1 , where ΔT P =ΔT W ;

[0124] Step 23, when the torque sensor collects the torque value P n+1 After that, the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com