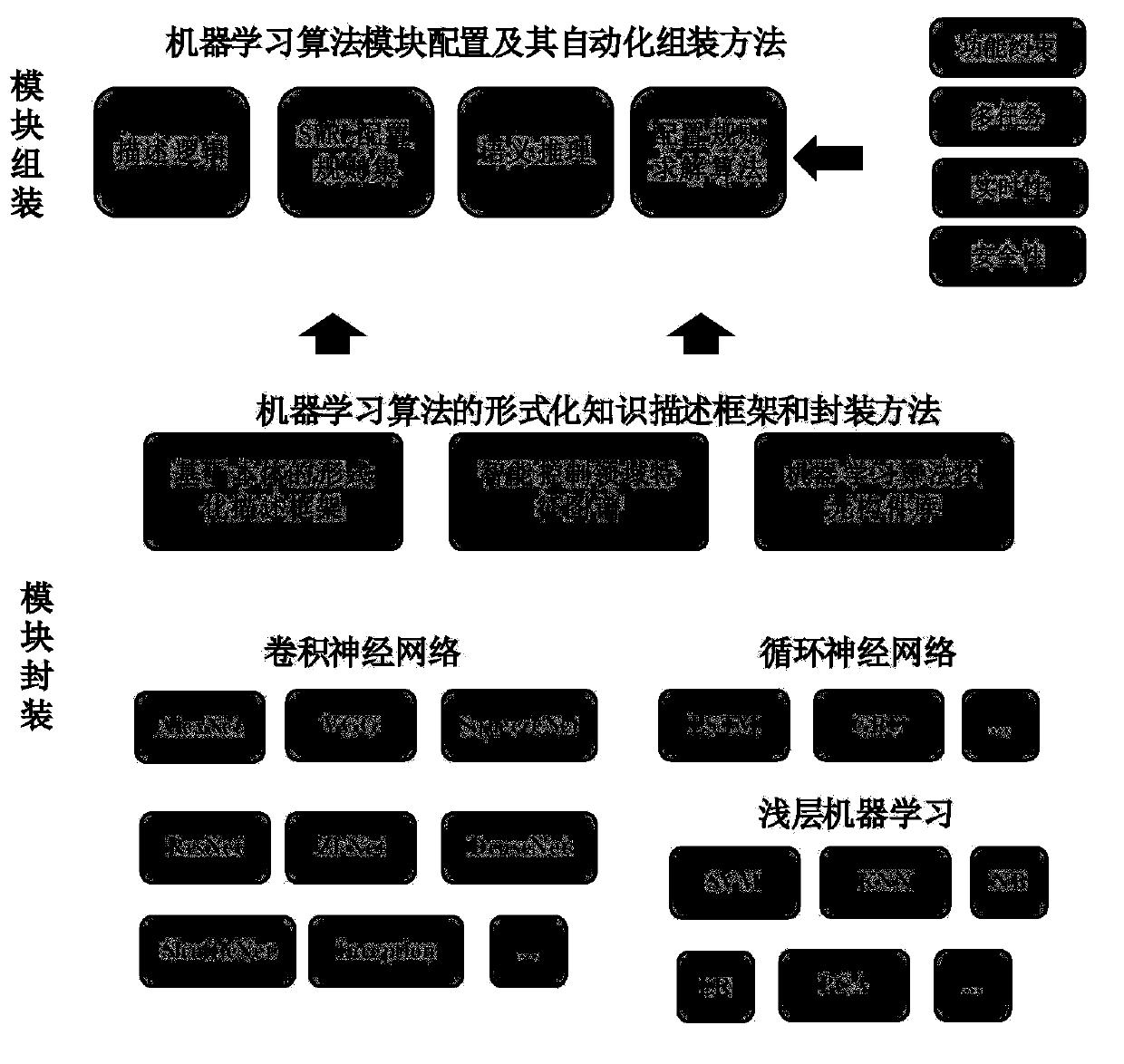

Machine learning algorithm module configuration and automated assembly method for intelligent controller

An intelligent controller and machine learning technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as assembly of embedded intelligent controller algorithm modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The production process of intelligent controller software products based on software assembly can be divided into two steps: feature selection under the constraints of feature configuration dependencies and feature realization software product selection under the constraints of non-functional application requirements. The former is based on the feature model and establishes a set of features and their relationships that meet the feature configuration dependencies and constraints according to the functional requirements of the specific application. The latter obtains software products that implement the selected features according to the non-functional requirements of the specific application. to assemble.

[0047] Correspondingly, the configuration of software products for intelligent controllers can be divided into two stages: feature configuration and algorithm primitive component configuration, which are used to obtain feature sets and machine learning algorithm primi...

Embodiment 2

[0056] The production process of intelligent controller software products based on software assembly can be divided into two steps: feature selection under the constraints of feature configuration dependencies and feature realization software product selection under the constraints of non-functional application requirements. The former is based on the feature model and according to the functional requirements of the specific application, establishes a set of features and their relationships that meet the feature configuration dependencies and constraints, that is, configuration modeling, and generates the corresponding SWRL configuration rule base; the latter is obtained according to the non-functional requirements of the specific application. Realize the software products with the selected features and assemble them according to the architecture of the intelligent control domain. This process is to use the configuration rule solver to perform semantic reasoning and solve the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com