Manual volume measurement system for monitoring compliance and working method thereof

A volume measurement and working method technology, applied in the field of manual volume measurement systems, can solve problems such as low efficiency, data errors, and no prompts, and achieve the effects of high measurement efficiency, less error-prone, and labor-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

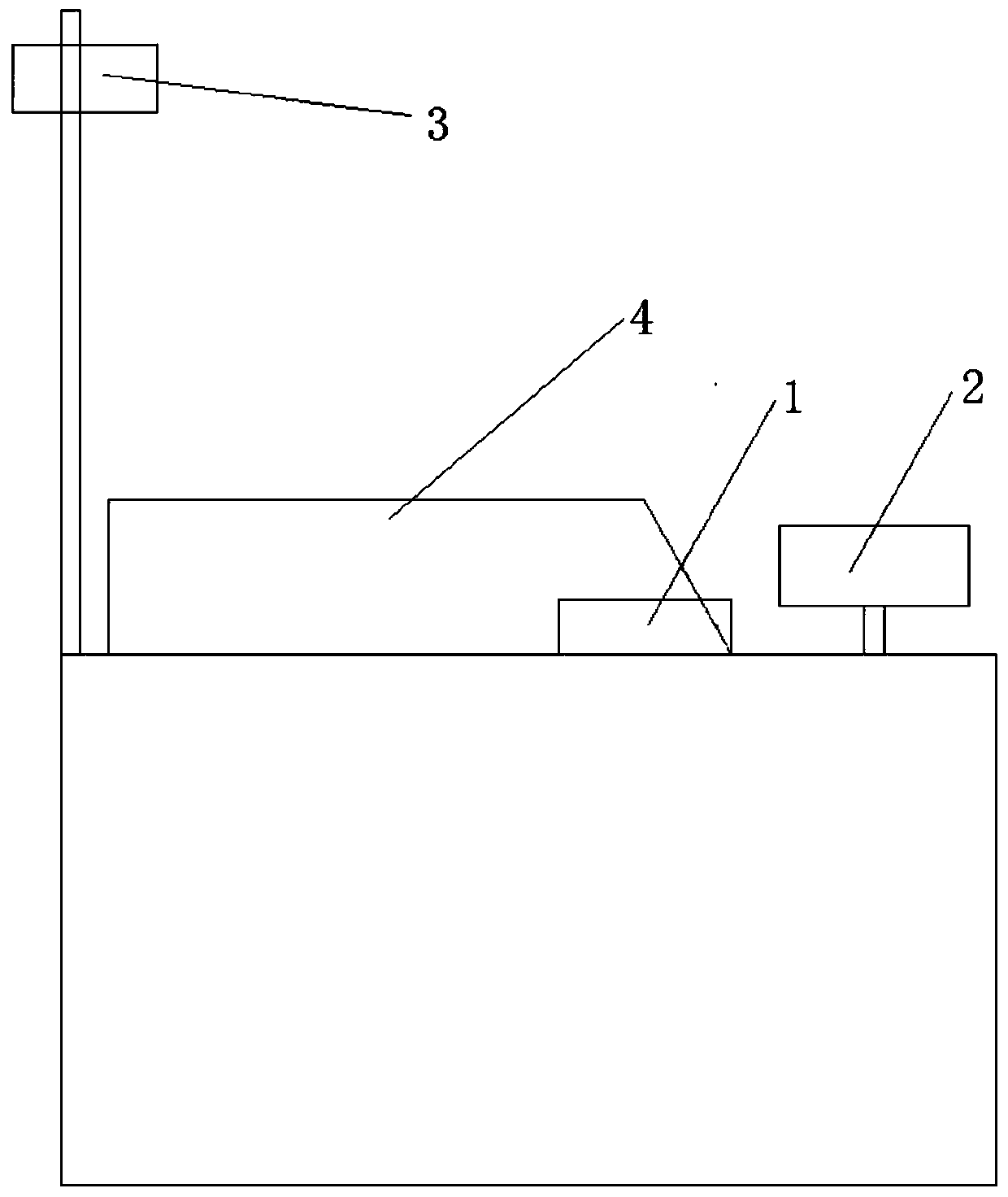

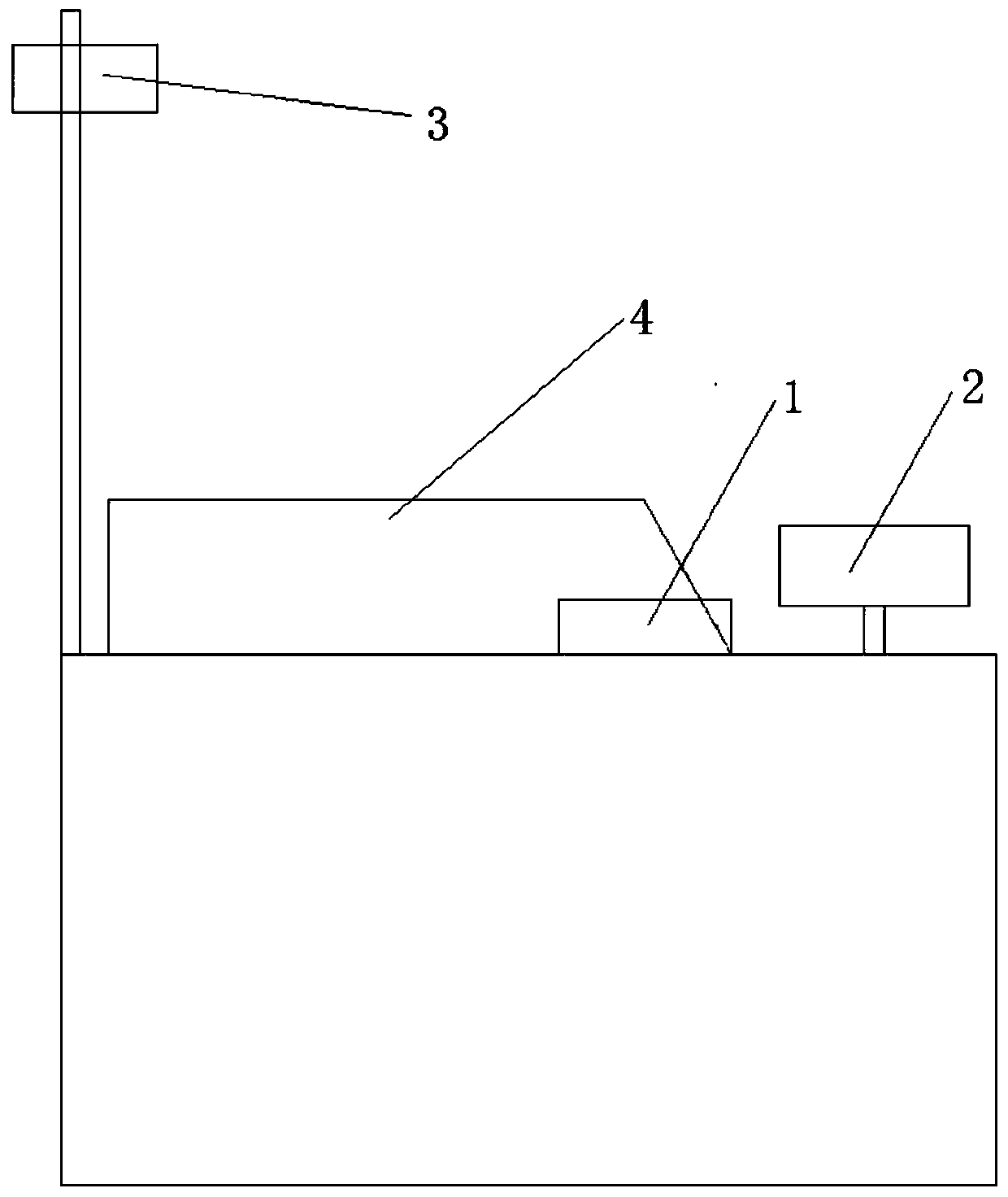

[0053] Such as figure 1 As shown, a manual volume measurement system for monitoring compliance, which includes a smart terminal 2 and a volume measuring instrument 1 and a photographing device 3 respectively connected to the smart terminal 2 by signals; wherein,

[0054] The volume measuring instrument 1 is suitable for measuring the length, width, and height of the object to be measured; and the volume value calculated according to the length, width, and height; and sending the length, width, height, and volume value to the intelligent terminal 2;

[0055] The smart terminal 2 is adapted to trigger the photographing device 3 to take pictures when the measurer confirms the length, width and height of the object to be measured;

[0056] The photographing device 3 is adapted to take photos of the object to be measured when the object to be measured is measured under the trigger of the smart terminal 2, and send the photos to the smart terminal 2;

[0057] The smart terminal 2 i...

Embodiment 2

[0068] A method of operation of a manual volume measurement system for monitoring compliance, the method steps comprising:

[0069] The object to be measured is placed on the weighing platform of the weighing device 4, and the weighing device 4 weighs the weight value of the object to be measured;

[0070] Use the scanning gun to scan the information identification code of the object to be tested, and the scanning gun sends the scanned identification information to the smart terminal 2;

[0071] The smart terminal 2 takes the received identification information as a trigger signal to read the weight value taken by the weighing device 4 and trigger the photographing device 3 to take pictures;

[0072] Use the volume measuring instrument 1 to measure the length of the object to be measured, press the confirmation key of the volume measuring instrument 1, the volume measuring instrument 1 will send the length to the smart terminal 2 and trigger the shooting device 3 to take pictu...

Embodiment 3

[0083] The method of this embodiment is basically the same as that of Embodiment 1, the difference is that: in the method steps in Embodiment 2, "place the object to be measured on the weighing platform of the weighing device 4, and the weighing device 4 weighs the object to be measured The weight value of the object; use the scanning gun to scan the information identification code of the object to be measured, and the scanning gun sends the scanned identification information to the intelligent terminal 2; the intelligent terminal 2 takes the received identification information as a trigger signal to read the weighing device 4 to weigh weight value and trigger the shooting device 3 to take pictures;”

[0084] Replaced with "Use a scanning gun to scan the information identification code on the object to be tested, the scanning gun sends the scanned identification information to the smart terminal 2, and the smart terminal 2 uses the received identification information as a trigg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com