Novel double-input-arc bevel gear reduction gearbox

A technology of spiral bevel gear and reduction box, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., to achieve the effect of improving utilization, improving transmission accuracy and strength, and reducing backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

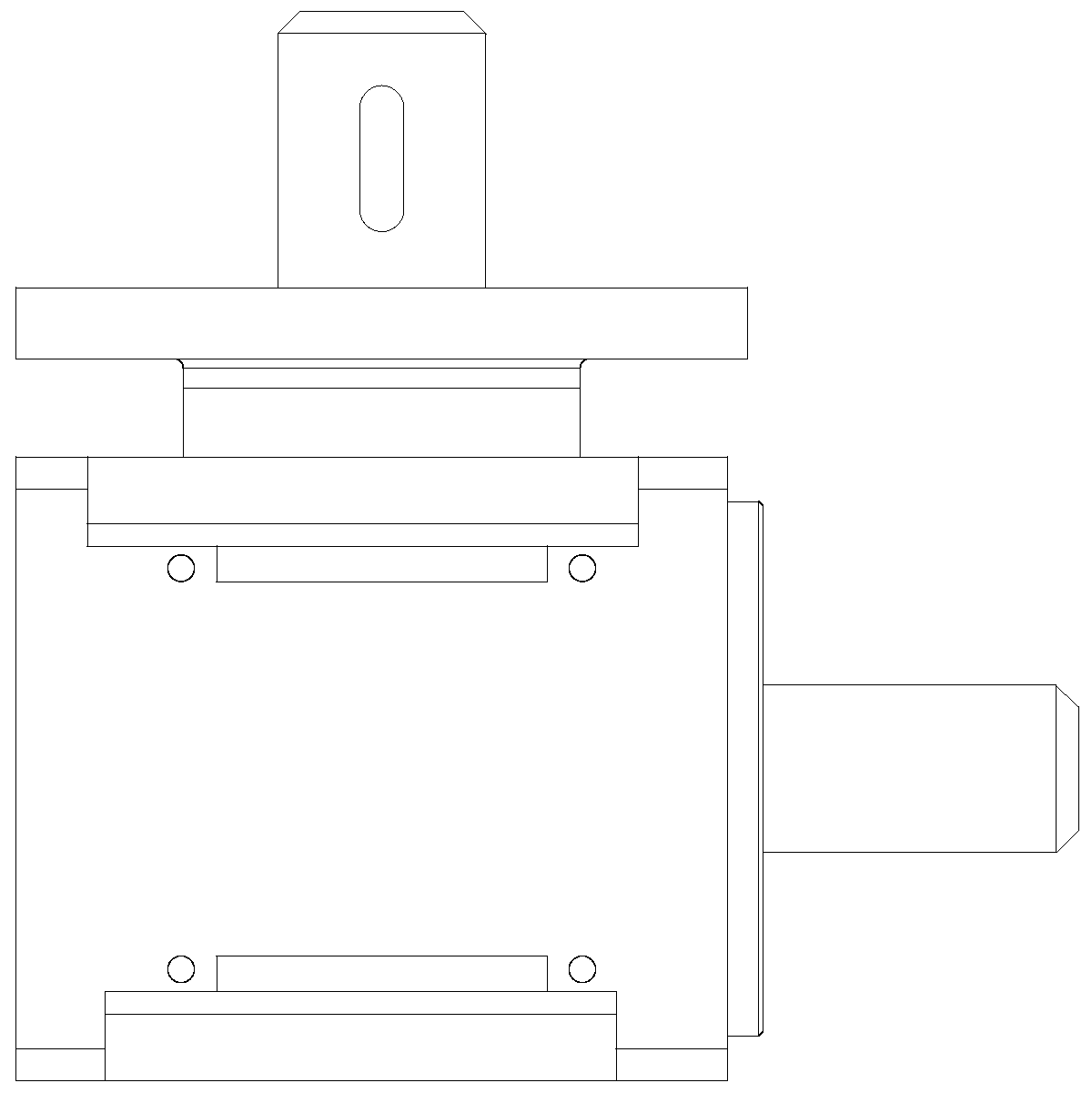

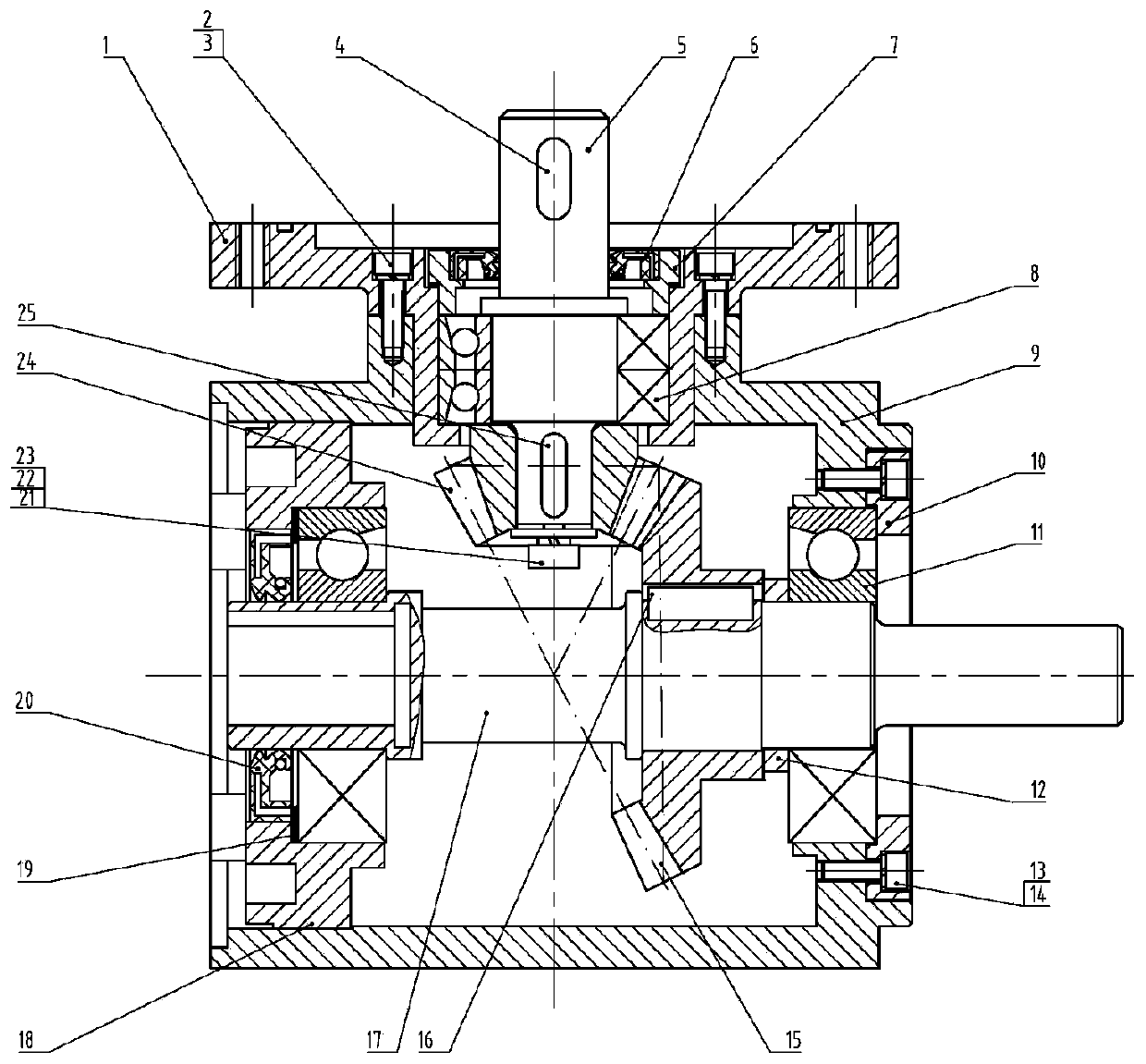

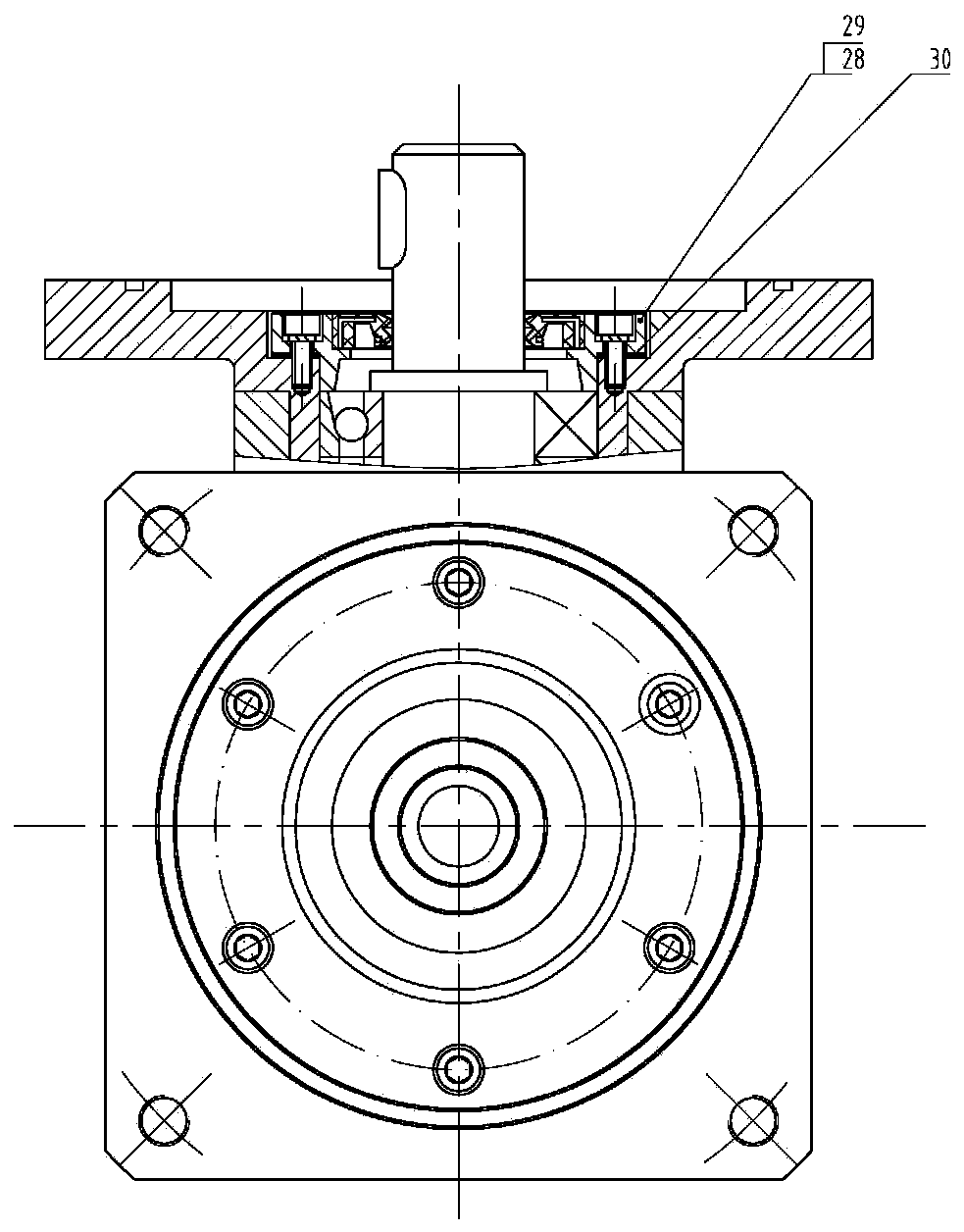

[0015] combine Figure 1 to Figure 7 , a new type of double-input spiral bevel gear reducer, including upper end cover 1, screw 2, washer 3, flat key 4, hand wheel shaft 5, oil seal 6, bearing end cover 7, angular contact ball bearing 8, box body 9, Right end cover 10, angular contact ball bearing 11, sleeve 12, screw 13, washer 14, large bevel gear 15, flat key 16, long shaft 17, left end cover 18, bearing gasket 19, oil seal 20, screw 21, washer 22 , Pinion baffle 23, pinion bevel gear 24, key 25, screw 26, washer 27, screw 28, washer 29, adjusting gasket 30.

[0016] The upper end face, the left end face and the right end face openings of the box body 9 are respectively provided with an upper end cover 1, a left end cover 18, and a right end cover 10, the outer ring of the upper bearing 8 is fixed on the upper end cover 1, and the hand wheel shaft 5 passes through the upper end cover 1 , the upper bearing 8 extends into the inner cavity of the box body 9, the handwheel sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com