Method for operating belt drive device

A technology of belt transmission and belt, which is applied in the direction of transmission, belt/chain/gear, machine/engine, etc., can solve the problems of belt slip, slipping, belt slipping, etc., and achieve the effect of fast attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

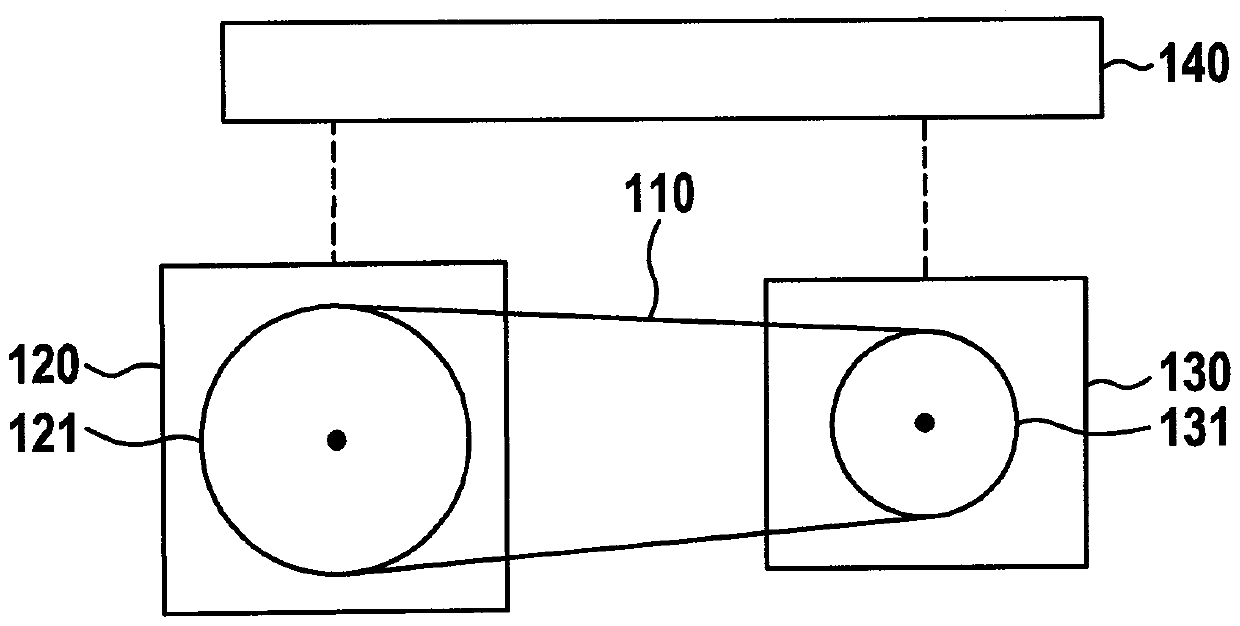

[0048] exist figure 1 A belt drive of a motor vehicle is schematically shown in and denoted by 100 .

[0049] Via the belt 110 of the belt drive 100 , the internal combustion engine 120 of the motor vehicle is connected for torque transmission to an electric machine 130 in the form of a belt-driven starter generator.

[0050] The internal combustion engine 120 and the electric machine 130 each have a belt pulley 121 or 131 , which are connected via a belt 110 for torque transmission. Belt pulley 121 of internal combustion engine 120 can be designed, for example, as a crankshaft drive wheel, and belt pulley 131 of electric machine 130 can be designed, for example, as a drive wheel of starter generator 130 .

[0051] Starter generator 130 can be operated as a motor, for example for starting or supporting internal combustion engine 120 , torque being transmitted from belt pulley 131 of starter generator 130 to belt pulley 121 of internal combustion engine 120 . During generator...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap