Multifunctional heat dissipation case for electric forklift

An electric forklift, multi-functional technology, applied in the field of forklifts, can solve the problem of poor heat dissipation effect of the battery, and achieve the effect of good heat dissipation effect, ensuring cleanliness and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

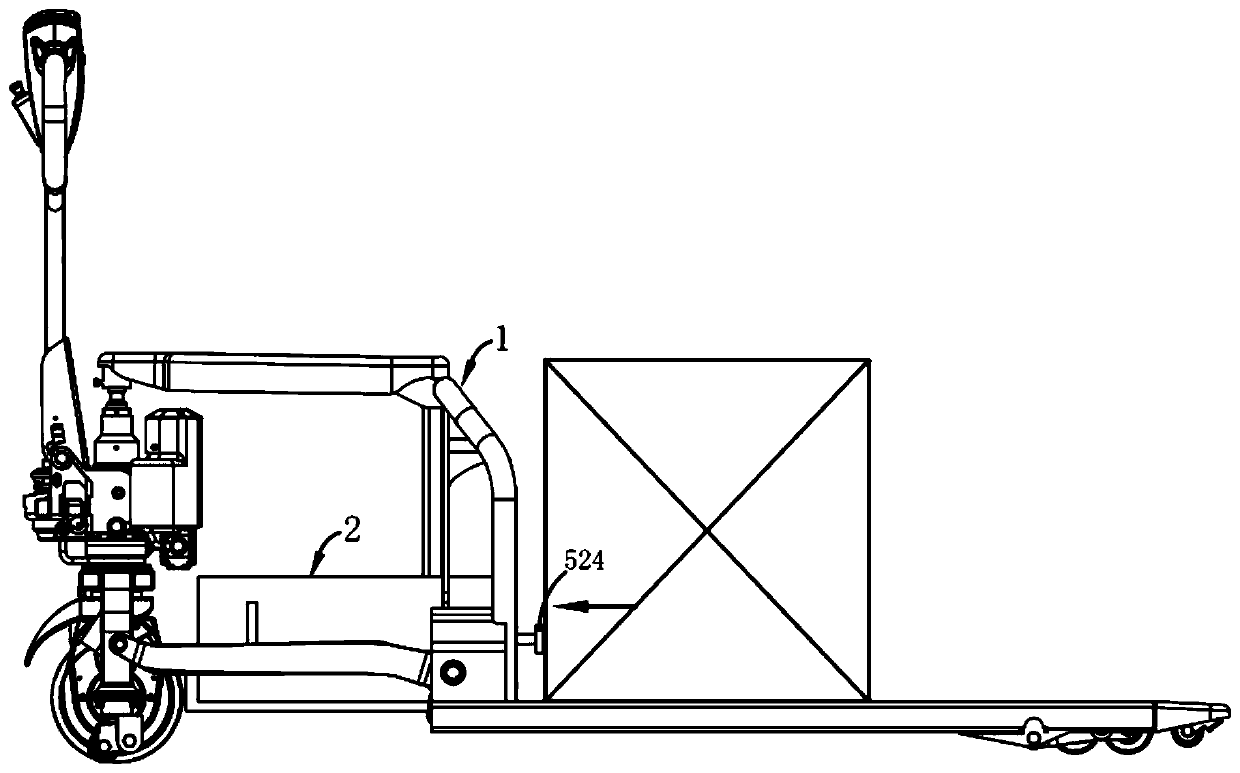

[0035] Such as Figures 1 to 4 As shown, a multifunctional heat dissipation chassis for an electric forklift includes a power storage device 2 arranged on the vehicle frame 1 for driving the forklift, and the power storage device 2 includes:

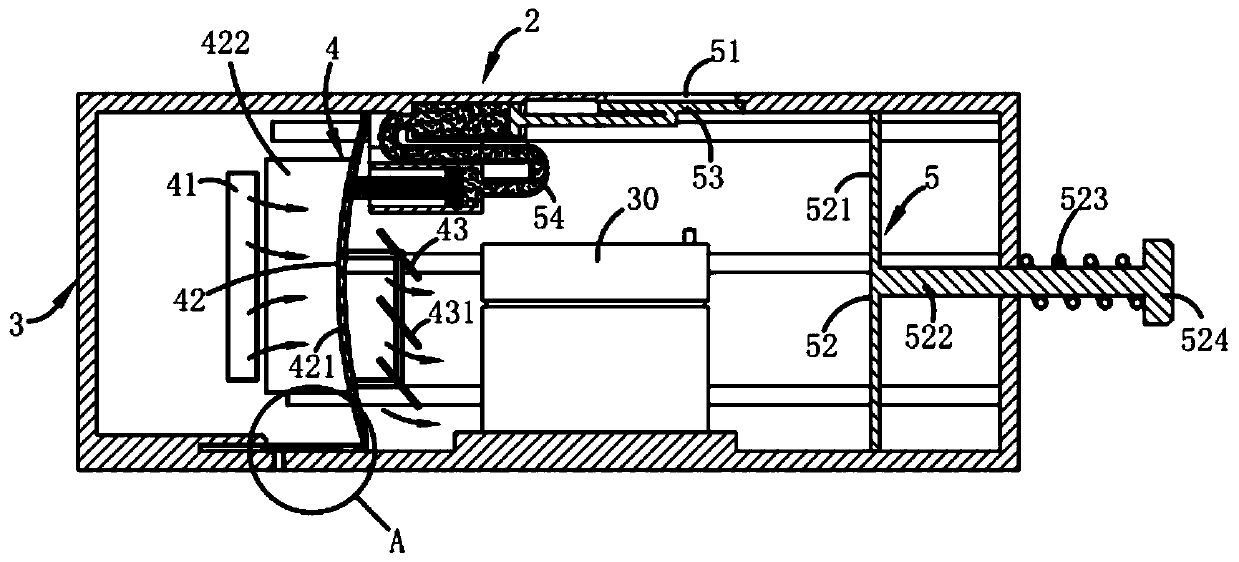

[0036] Case 3, the case 3 is used to place the storage battery 30;

[0037] Dust-proof mechanism 4, the dust-proof mechanism 4 is used to remove dust from the airflow entering the chassis 3, the dustproof mechanism 4 includes an airflow passage A41 opened on the chassis 3, an airflow passa...

Embodiment 2

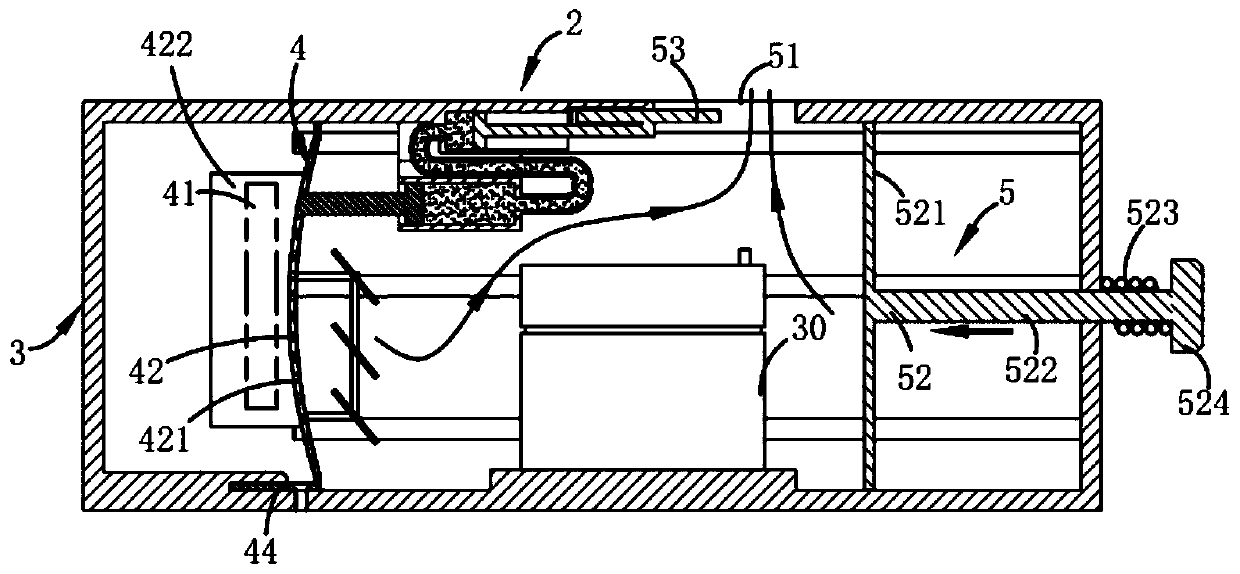

[0043] Such as figure 2 with 4 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that the airflow guiding part 43 is connected to the filter screen 421 and includes a plurality of air deflectors 431 distributed successively along the vertical direction. The airflow drives the wind deflector 431 to swing; in this embodiment, the wind deflector 431 is set as a light flat plate structure, and the wind deflector 431 is set by free rotation to realize the change of the inclination angle of the wind deflector 431 through the change of the air flow direction When the airflow enters the chassis 3 through the airflow channel A41, it is guided by the air deflector 431, so that the airflow flows to the bottom of the b...

Embodiment 3

[0046] Such as Figures 2 to 4 As shown, the parts identical or corresponding to those in the second embodiment adopt the reference numerals corresponding to the second embodiment. For the sake of simplicity, only the differences between the second embodiment and the second embodiment are described below; the difference between the third embodiment and the second embodiment The difference is that: the exhaust passage B51 is opened on the top of the chassis 3 and located above the battery 30, the exhaust passage B51 is arranged in cooperation with the sealing plate 53, and the sealing plate 53 and the filter assembly 42 is connected, and the sealing plate 53 is controlled to open and close the exhaust channel B51 through the movement of the filter assembly 42 .

[0047] Further, such as figure 2 with 8 As shown, the heat dissipation mechanism 5 also includes a hydraulic transmission part 54 connecting the sealing plate 53 and the filter assembly 42. The hydraulic transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com