Simple constant-pressure fixture

A simple and simple technology for clamping, applied in clamping, manufacturing tools, supports, etc., can solve the problems of complicated fixture operation, inability to achieve rapid clamping, and inability to well adapt to the clamping needs of workpieces of different thicknesses, and achieve the structure of the fixture. Simple, suitable for mass production, avoids the effect of insufficient pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

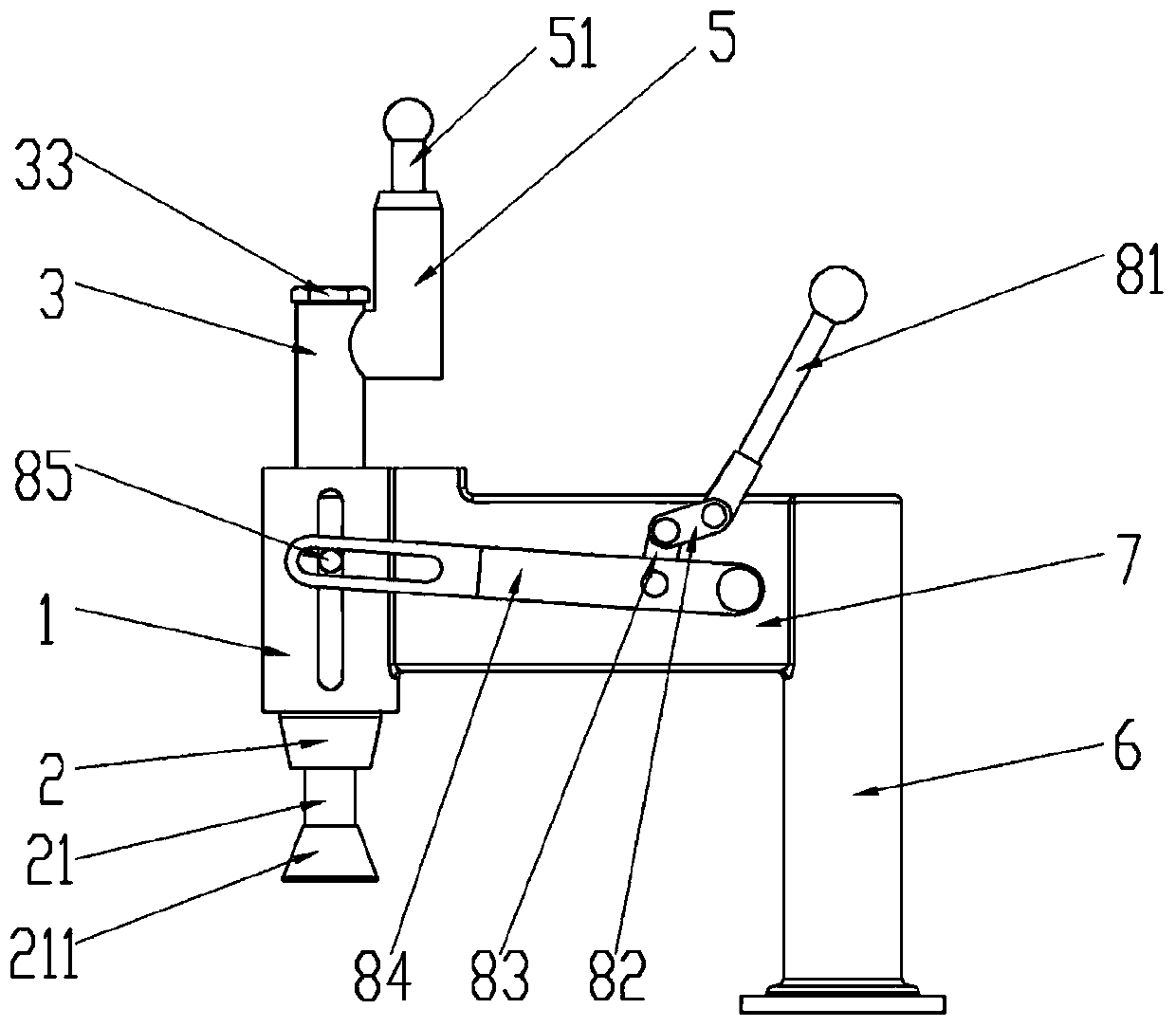

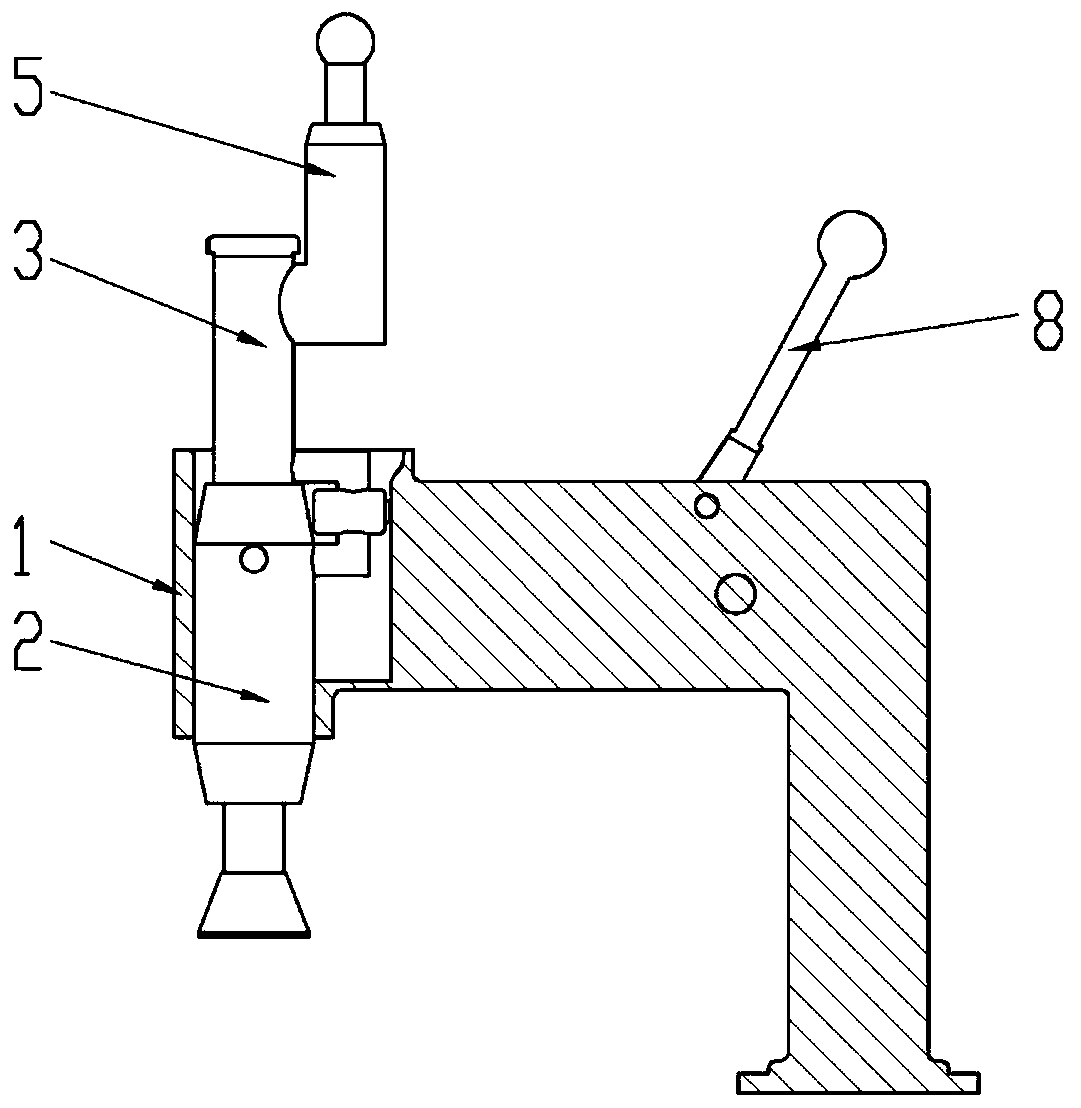

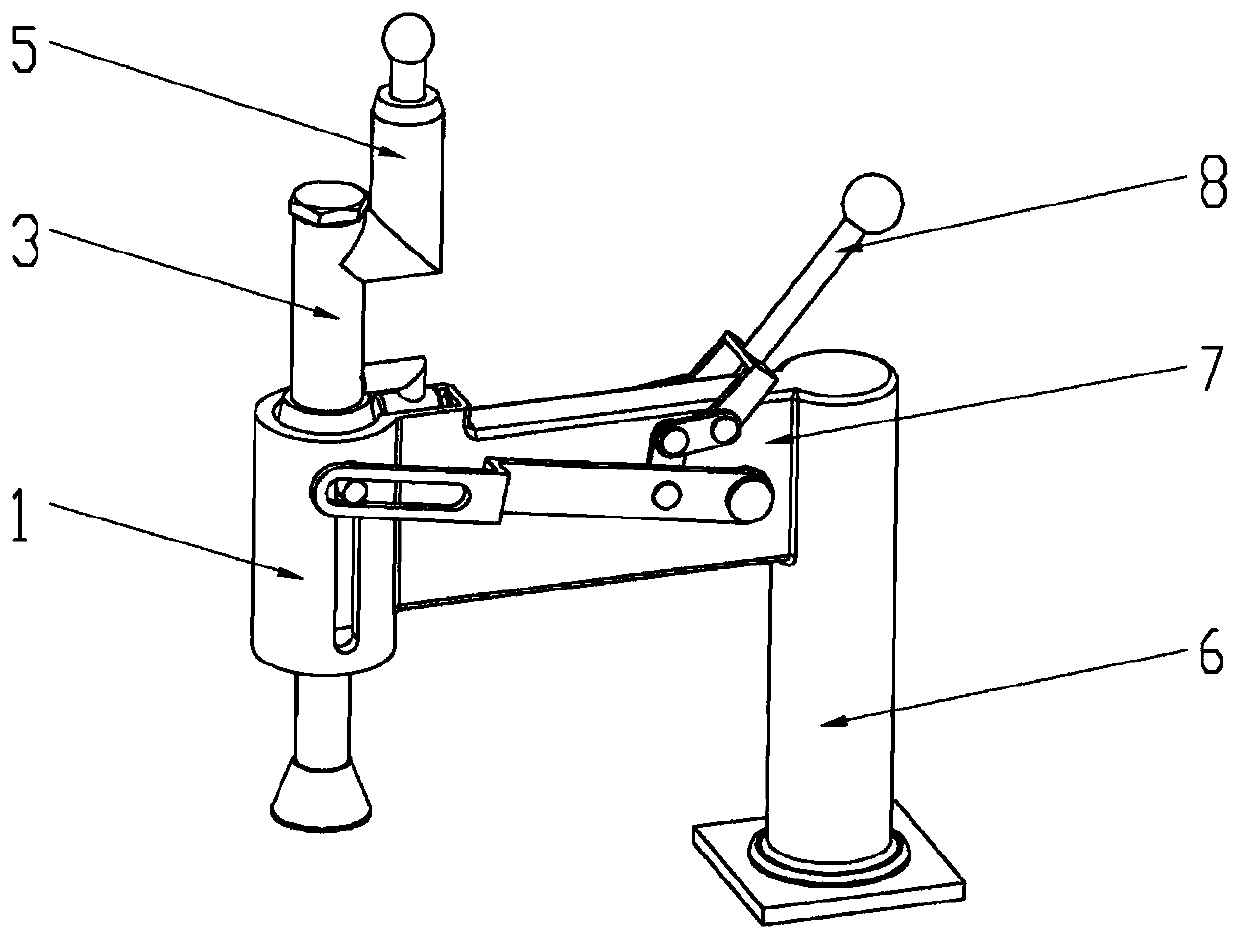

[0038] refer to Figure 1 to Figure 9 , the present application provides a simple constant pressure fixture, including a guide sleeve 1 , a pressing cylinder 2 and an upper cylinder 3 .

[0039] Wherein, the compression cylinder 2 is arranged in the guide sleeve 1 and can slide back and forth along the length direction of the guide sleeve 1. The compression cylinder 2 is provided with a compression piston 21. The cavity between them is filled with a liquid medium. The bottom end of the upper oil cylinder 3 is fixedly connected with the top end of the compression oil cylinder 2 and communicates with each other. A pressure limiting barrier 31 is placed at the place where the two communicate with each other. A pressure limiting spring 32 is arranged in the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com