Positioning grid special-shaped spot-welding electrode

A technology for positioning grids and spot welding electrodes, which is applied in welding media, welding equipment, welding/cutting media/materials, etc., to stabilize the quality of welding spots, save spot welding time, and have a good fit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

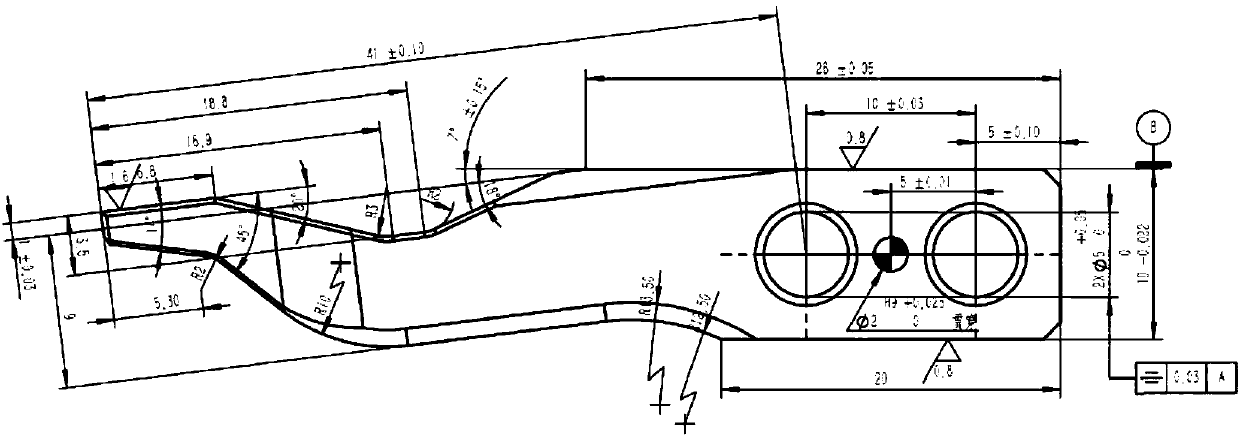

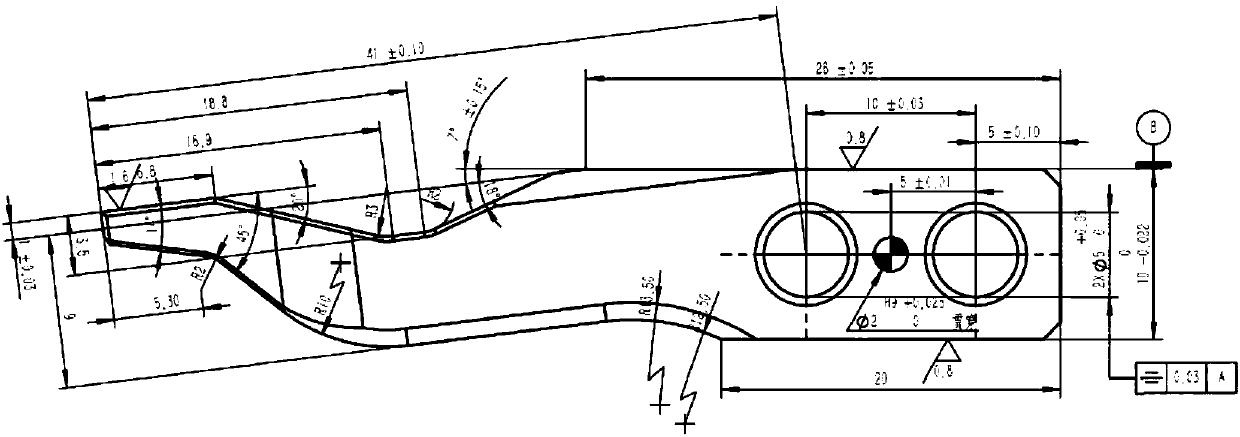

[0014] Such as figure 1 with figure 2 As shown, a special-shaped spot welding electrode with a positioning grid is in the shape of a long plate as a whole and is divided into three parts: left, middle and right. The left part is a terminal, the shape is a right-angled trapezoid, the left end is an upper base, the upper end is a right-angled side, and the lower end is a hypotenuse. The included angle between the right-angled side and the horizontal line is 6.85° to 7.15°, and the included angle between the hypotenuse and the right-angled side is 14°. The middle part is an arc segment, the whole is "S" shape, the upper end is a "V" concave part, the angle between the left side of the "V" shape and the right-angled side of the end is greater than or equal to 20°, the right side of the end and the horizontal line The included angle is greater than or eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com