Gas purification device

A technology of gas purification device and gas cylinder, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of secondary pollution, high processing cost, small filtration flow rate, etc., and achieve convenient replacement of filter elements, high adsorption efficiency, The effect of filtering large flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

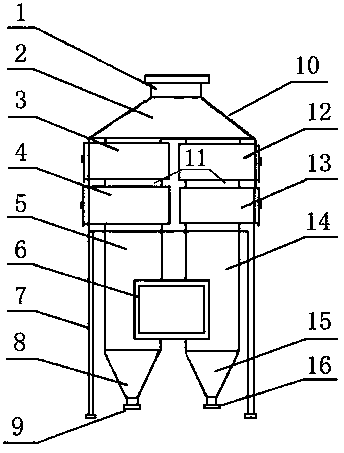

[0010] As shown in the accompanying drawings, a gas purification device consists of an air outlet pipe 1, a purification gas collection cover 2, a pull-out activated carbon filter layer a3, a pull-out activated carbon filter layer b4, an air cylinder a5, an air inlet 6, and legs 7. Dust collecting slag hopper a8, dust slag discharging pipe a9, body 10, connecting pipe 11, pull-out activated carbon filter layer c12, pull-type activated carbon filter layer d13, gas cylinder b14, dust-collecting slag hopper b15, exhaust Composed of dust and residue pipe b16; the upper part of the device body 10 is provided with a purification gas collection cover 2 that takes out the air pipe 1, and one side of the device body 10 is provided with a pull-out activated carbon filter layer a3 and a pull-out activated carbon filter layer b4, and the other side is provided with a Pull-out activated carbon filter layer c12 and pull-out activated carbon filter layer d13, device legs 7 are set around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com