Water circulating device for cleaning lower case of battery to remove aluminum scraps

A technology for water circulation and aluminum scraps, which is applied to the field of water circulation equipment for cleaning aluminum scraps in the lower casing of batteries, can solve problems such as wasting water resources for cleaning effects, and achieve the effects of low efficiency, ensuring production safety, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

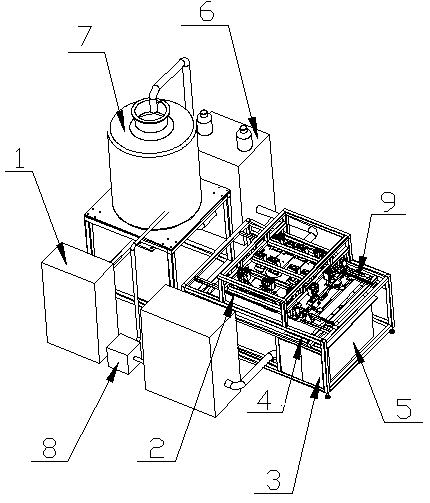

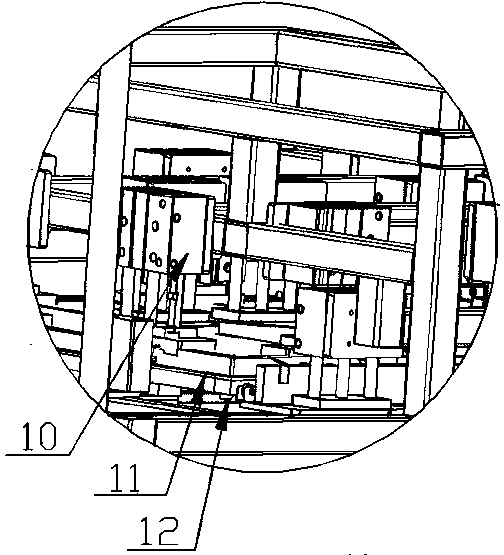

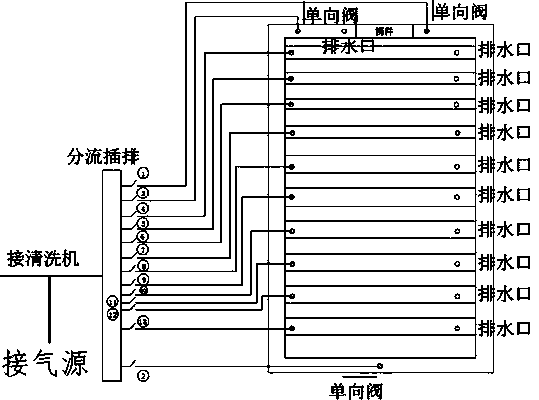

[0025] see Figure 1-Figure 5 , a water circulation device for cleaning aluminum chips in the battery lower shell, the cycle device includes a high-pressure cleaner module 1, a seal cleaning tooling module 2, a cleaning pipeline module 3, a coarse filter module for aluminum chips 4, a primary buffer water tank module 5, Aluminum chip fine filter module 6, secondary buffer water tank module 7, booster pump module 8, and loading and unloading module 9; the seal cleaning tooling module 2 includes a pressing cylinder 10, a sealing silicone pad 11, and a water filling and drain structure 12. The cleaning pipeline module 3 includes a high-pressure pipeline 13, a solenoid valve 14 for high-pressure water and a one-way valve 15; during cleaning operations, the high-pressure cleaner module 1 injects water into the machined hole of the lower shell that needs to be cleaned, The remaining processing holes are sealed by the silica gel pad in the sealing and cleaning tooling module 2, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com