Method and device for operating an internal combustion engine

A technology for internal combustion engines and fuels, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as cylinder torque differences, internal combustion engine running stability, or adverse effects on emission performance, so as to avoid fine-tuning and reduce inaccurate error diagnosis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

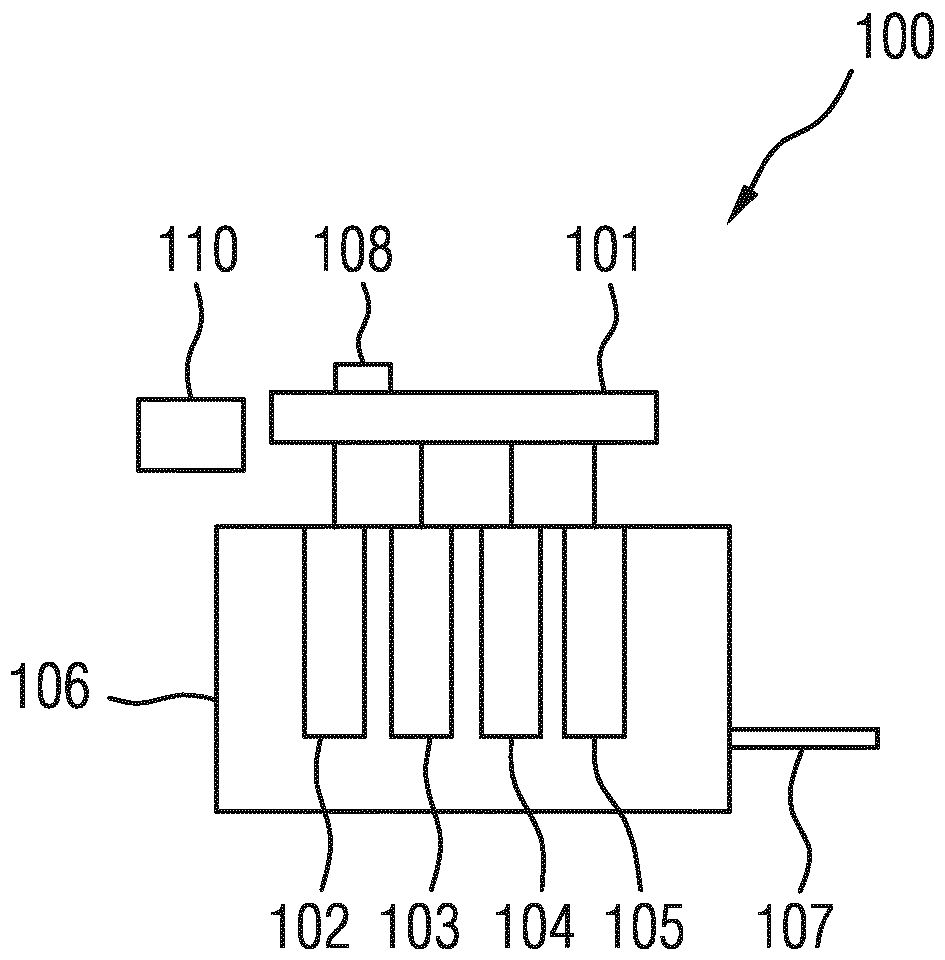

[0031] figure 1 A system 100 is shown with an internal combustion engine 106 and a fuel distributor 101 (also referred to as a common rail). Fuel from a fuel tank (not shown) is accumulated under high pressure in fuel distributor 101 and then injected directly into cylinders 102 , 103 , 104 and 105 of internal combustion engine 106 . Combustion of the injected fuel results in a torque output from the cylinders 102 to 105 to a crankshaft 107 of the internal combustion engine 106 . In the exemplary embodiment shown, internal combustion engine 106 has four cylinders 102 to 105 . According to other exemplary embodiments, the internal combustion engine has more or less than four cylinders. Cylinders 102 to 105 can also be referred to as combustion chambers of internal combustion engine 106 .

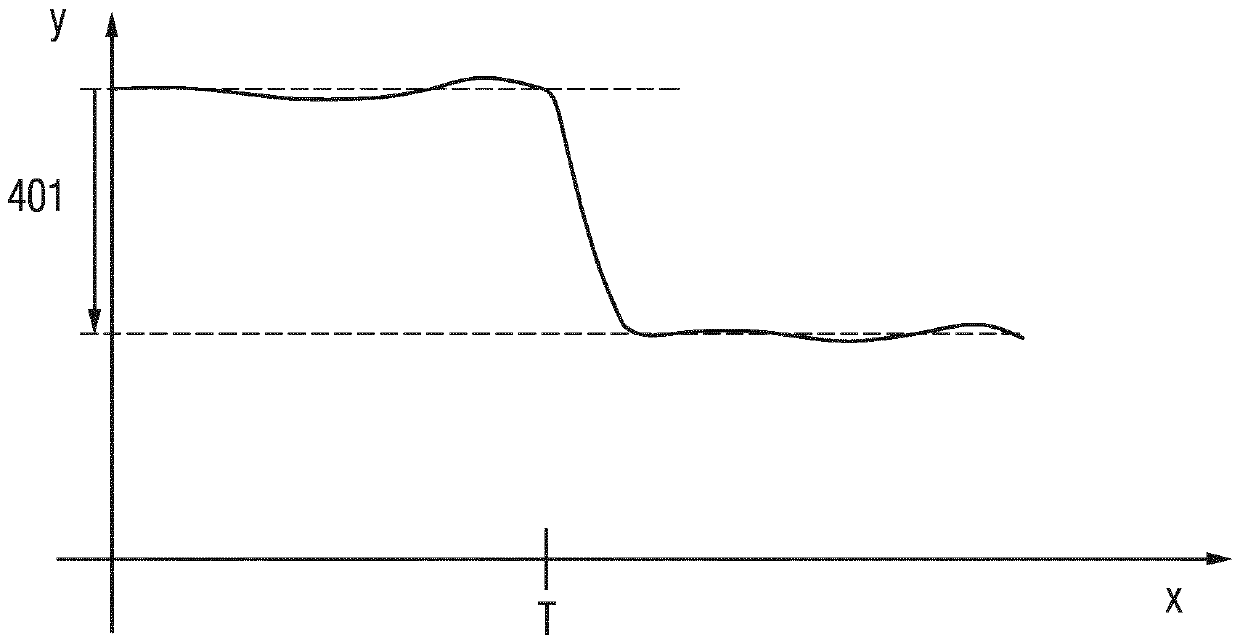

[0032] The actual amount of fuel injected may vary between the individual cylinders 102 - 105 based on manufacturing tolerances within the system 100 and due to aging phenomena. For examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com