Motor magnetic steel

A magnetic steel and curved surface technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of low load speed, high noise, large load current, etc., and achieve the effect of reducing motor torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

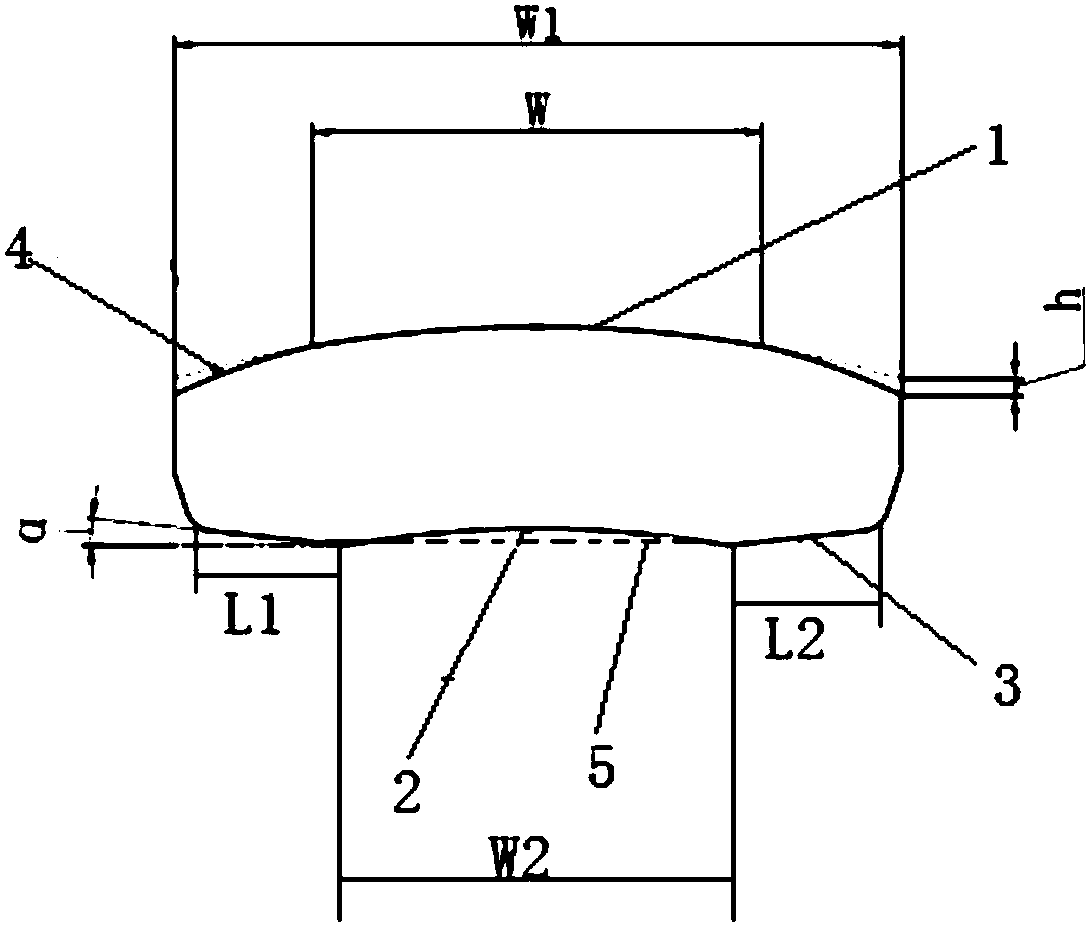

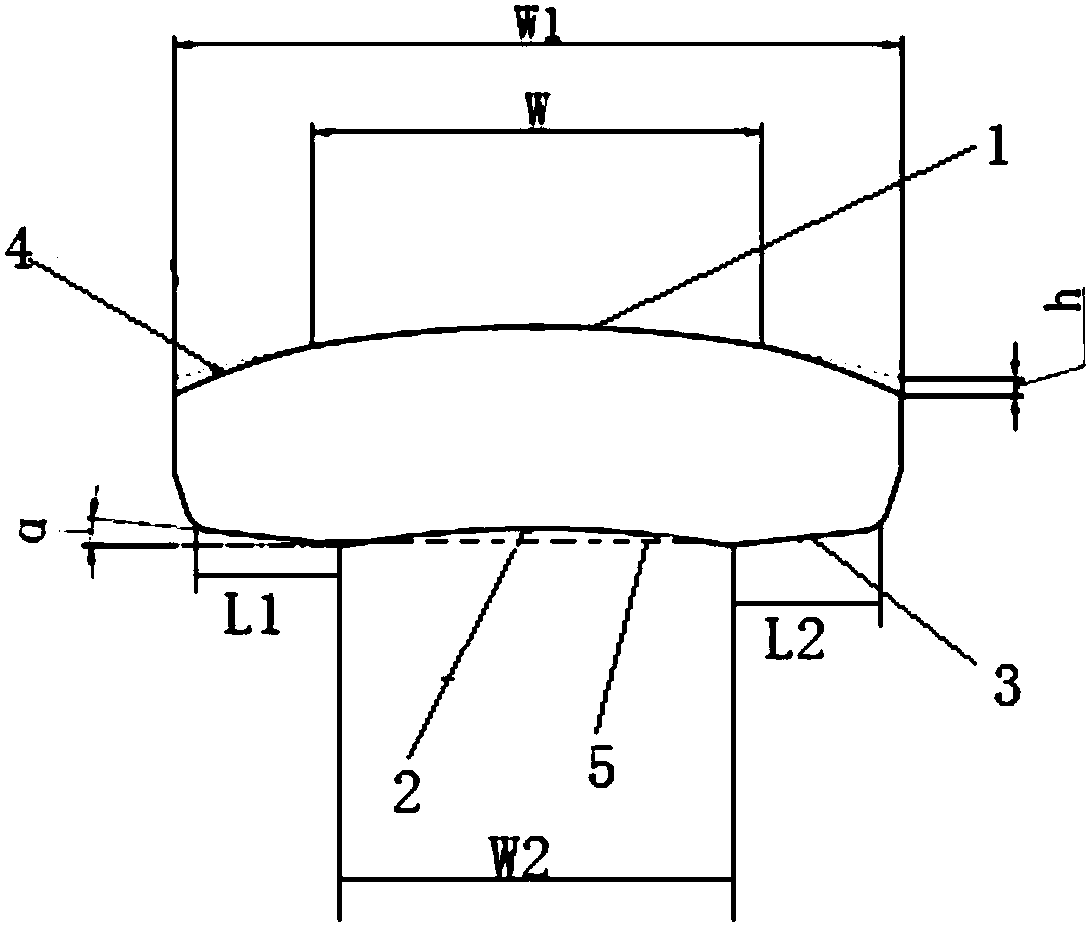

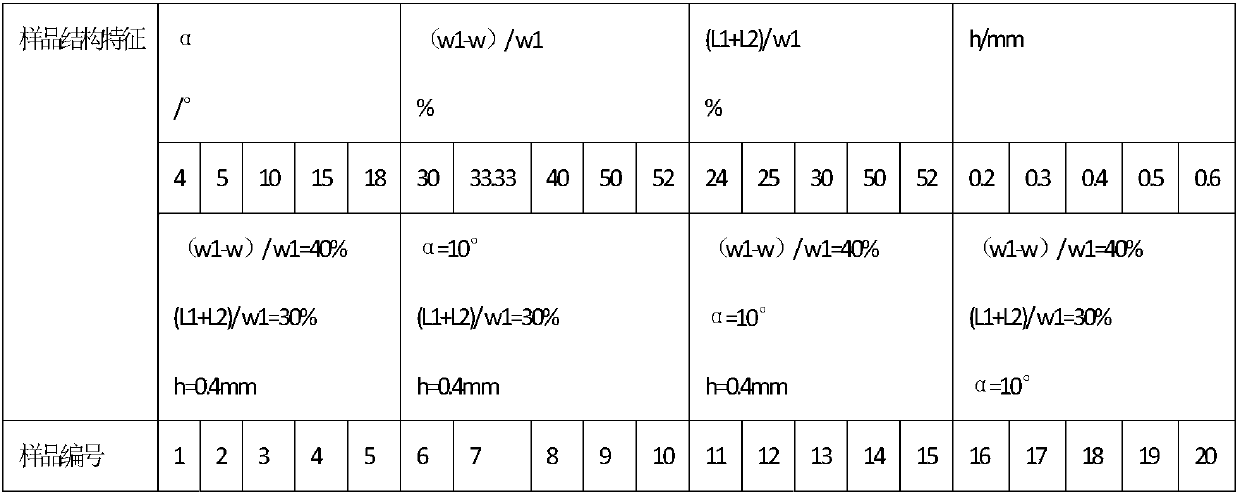

[0011] Embodiment 1: adopt the same batch of molding slurry, under the same molding, sintering, detection process conditions, the product made, such as figure 1 Combined with sample No. 2 in Table 1, it is a motor magnet. The radian of the outer arc surface of the magnet body is determined according to the motor shell to ensure that the magnet and the motor shell are firmly attached. The two ends of the outer arc surface 1 respectively have an arc surface that transitions with the radian of the outer arc surface. There is a certain gap between the extension surface of the outer arc surface and the arc surface. This gap is an air gap, and this arc surface is an air gap transition arc 4. The center of the air gap transition arc 4 deviates from the center of the outer arc surface 1 of the magnetic steel, and the total width of the air gap (w1‐w) is 40% of the total width w1 of the magnetic steel (w1‐w) / w1=40%); the outer arc surface of the main body 1 The vertical distance h betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com