Current collector, cell and battery

A current collector, closed curve technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of increased battery cost, reduced battery safety, limited improvement in battery safety, etc. Short circuit area, control of heat build-up, effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of current collector

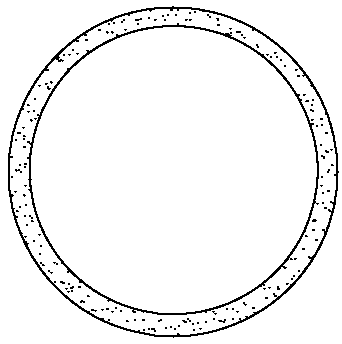

[0037] refer to Figure 10 , the aluminum foil with a thickness of 13 μm is pre-etched by laser, the laser travel speed is controlled to 100mm / s, the laser frequency is controlled to 300Hz, the laser duty cycle is controlled to 65%, and the laser etching pattern consists of multiple continuous or discontinuous Composed of a circle, the diameter of the circle is 3mm, the depth of the notch groove is 6μm, and the width of the notch groove is 10μm. Pay attention to dust control during the treatment process. After the laser etching is completed, the surface of the current collector is cleaned to remove the surface Metal shavings, which can then be coated with active substance slurries.

[0038] (2) Preparation of cathode sheet

[0039] The cathode active material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , the conductive agent Super-P, and the binder polyvinylidene fluoride are mixed in the N-methylpyrrolidone solvent system at a weight ratio o...

Embodiment 2

[0047] Prepare the battery according to the method of Example 1, the difference is:

[0048] (1) Preparation of current collector

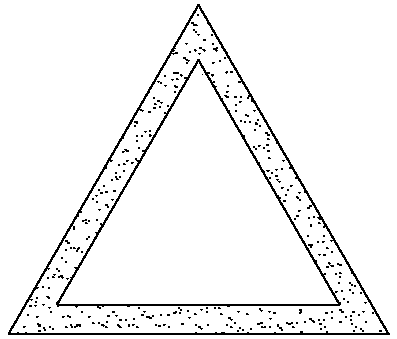

[0049] refer to Figure 11 , the aluminum foil with a thickness of 13 μm is pre-etched by laser, the laser travel speed is controlled to 100 mm / s, the laser frequency is controlled to 300 Hz, and the laser duty cycle is controlled to 65%. The laser etching pattern consists of multiple continuous squares, The side length of the square is 3mm, the depth of the notch groove is 6μm, and the width of the notch groove is 10μm. Pay attention to dust control during the treatment process. After the laser etching is completed, clean the surface of the current collector to remove the metal powder on the surface , and then the coating of the active material slurry can be carried out.

Embodiment 3

[0051] Prepare the battery according to the method of Example 1, the difference is:

[0052] (1) Preparation of current collector

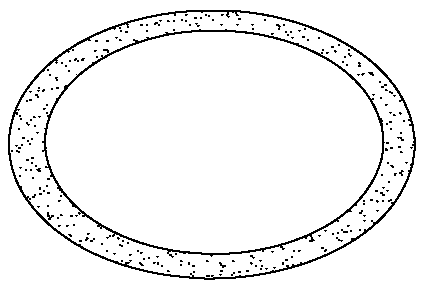

[0053] refer to Figure 12 , the aluminum foil with a thickness of 13 μm is pre-etched by laser, the laser travel speed is controlled to 100mm / s, the laser frequency is controlled to 300Hz, the laser duty cycle is controlled to 65%, and the laser etching pattern consists of multiple continuous square circumscribed circles The diameter of the circle is 3mm, the side length of the square is 2.121mm, the depth of the notch groove is 6μm, and the width of the notch groove is 10μm. Pay attention to dust control during the treatment process. The surface is cleaned to remove the metal powder on the surface, and then the coating of the active material slurry can be carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com