Automatic release device and washing machine

A technology of automatic feeding and detergent, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of low washing ratio, increase the cost of a single laundry, waste water, electricity and time, etc., achieve remarkable results and be suitable for promotion The effect of simple use and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

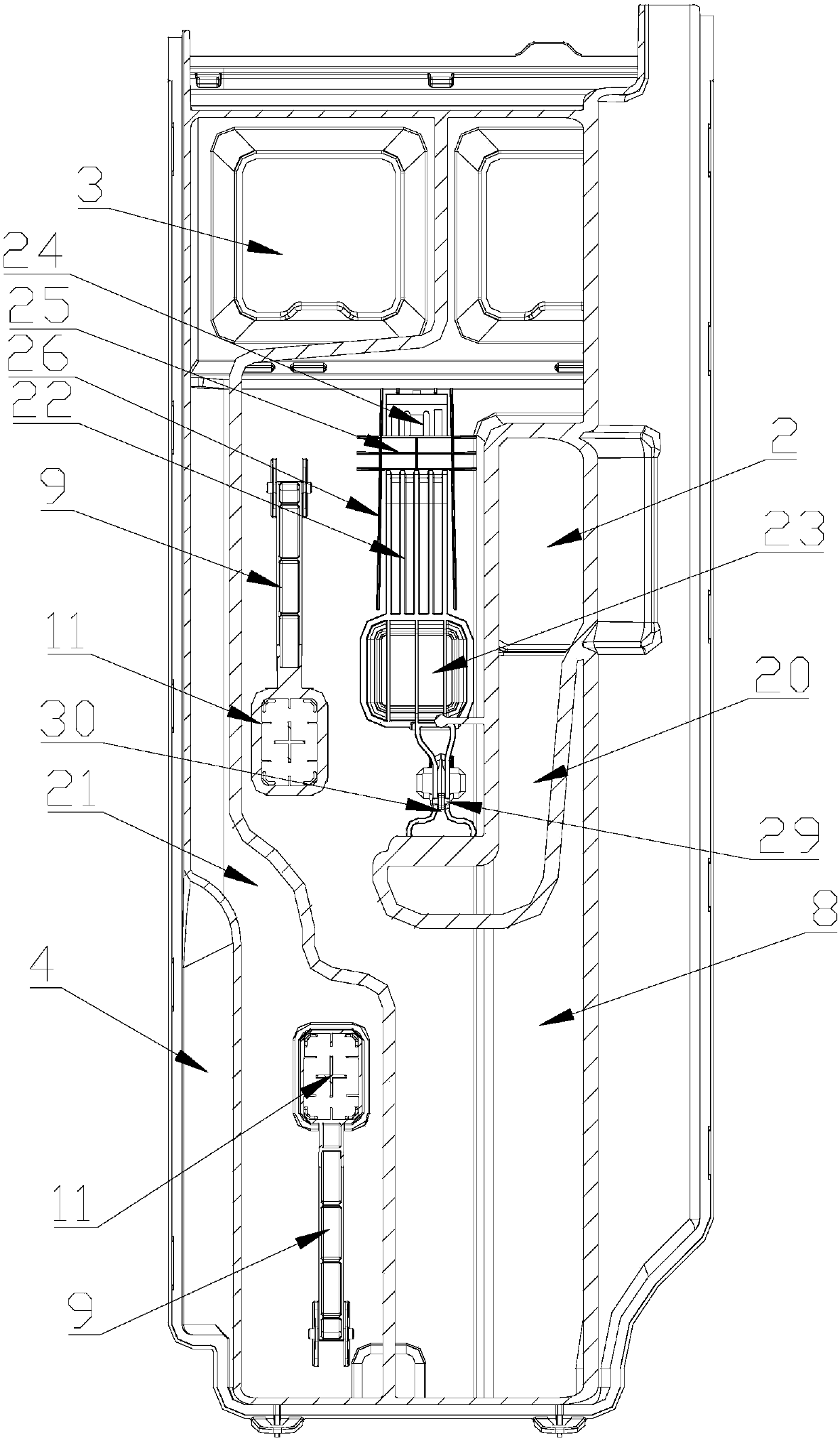

[0044] Such as Figure 1 to Figure 9As shown, this embodiment introduces an automatic delivery device, which includes a washing box 200, the detergent box 200 includes at least one chamber for containing detergent, the bottom of the chamber is provided with a liquid outlet 33, and the bottom of the chamber is provided with a The flow channel 31 is recessed, and the end of the flow channel 31 communicates with the liquid outlet 33 , so that the detergent remaining in the chamber can be discharged to the liquid outlet 33 along the flow channel 31 . A one-way valve 34 is installed at the liquid outlet 33 , so that the detergent or softener stored in the chamber flows out of the chamber through the one-way valve 34 .

[0045] By setting the flow channel connected with the liquid outlet at the bottom of the detergent box chamber, so that the liquids such as detergent stored in the chamber converge and flow to the flow channel, avoiding a large area of residual liquid at the botto...

Embodiment 2

[0054] Such as Figure 1 to Figure 9 As shown, this embodiment introduces an automatic dispensing device, which includes a drawable detergent box 200 installed in the water box 100. The detergent box 200 is equipped with a pressing rod 22 that is plugged and connected at one end. The pressing rod 22 The other end is provided with a locking tongue 28 that protrudes outwards, so that the locking tongue can be retracted toward the inside of the detergent box to release the locked state of the locking tongue after the user presses the pressure bar.

[0055] By installing a pressure rod that can produce elastic deformation under the action of external force on the detergent box, the user can press the pressure rod to make the lock tongue set on the pressure rod shrink and move, and then the lock tongue is separated from the water box. Or the purpose of locking the limit.

[0056] In this embodiment, the detergent box 200 includes a housing and an upper cover 4 fastened to the top....

Embodiment 3

[0067] Such as Figure 1 to Figure 9 As shown, an automatic dispensing device is introduced in this embodiment, which includes a detergent box 200. The detergent box 200 is provided with at least one chamber for detergent storage; the chamber is provided with a float 11 for floating and liquid surface A magnet 12 is provided inside the float 11 , and a reed switch 13 is correspondingly installed under the float 11 to detect the height of the float 11 and obtain the liquid level in the detergent box chamber 200 .

[0068] By installing a float that floats with the liquid level in the detergent and softener liquid storage chamber of the detergent box, and detecting the magnet set inside the float to obtain the height change of the float, and then achieve the liquid level in the detergent box chamber The purpose of high-speed and accurate detection is to issue an alarm in time to remind the user that the detergent and softener stored in the chamber are insufficient.

[0069] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com