Ink jetting device printing head for printed circuit board

An inkjet device and printed circuit technology, applied in printing devices, printing, typewriters, etc., can solve the problems of incomplete circuit boards, dry ink, inconvenient use, etc., and achieve the effects of convenient operation, convenient printing, and simple devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

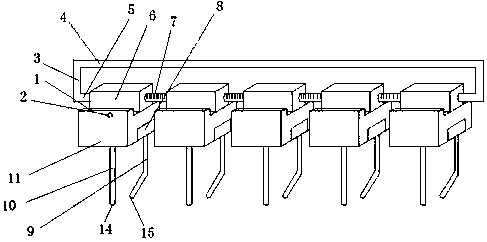

[0017] Such as Figure 1-2 Shown, a kind of printed circuit board inkjet device printing head comprises printing head device 11 and lateral connecting rod 3, and the lower end of described printing head device 11 is provided with inkjet tube 10 and oil outlet 14, and printing head The upper end of the device 11 is provided with a fixed connection post 6, one side of the fixed connection post 6 is provided with a card slot 1, one side of the print head device 11 is provided with a blower device 8, and the lower end of the blower device 8 is provided with a There is an air outlet duct 9 and an air outlet 15, the inside of the print head device 11 is provided with a piezoelectric device 13, and one side of the piezoelectric device 13 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com