Dimensional tooling and dimensioning method for large-size integrally formed heat-proof structure

An integral molding and shape-dimensional technology, applied in applications, household appliances, household components, etc., can solve the problems of low-density fiber three-dimensional structure easy to deform, size cannot maintain shape, etc., to solve the problem of structural dimension accuracy control and realize product maintenance. Shape, to ensure the effect of reshaping the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

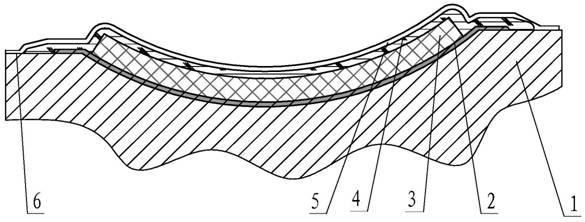

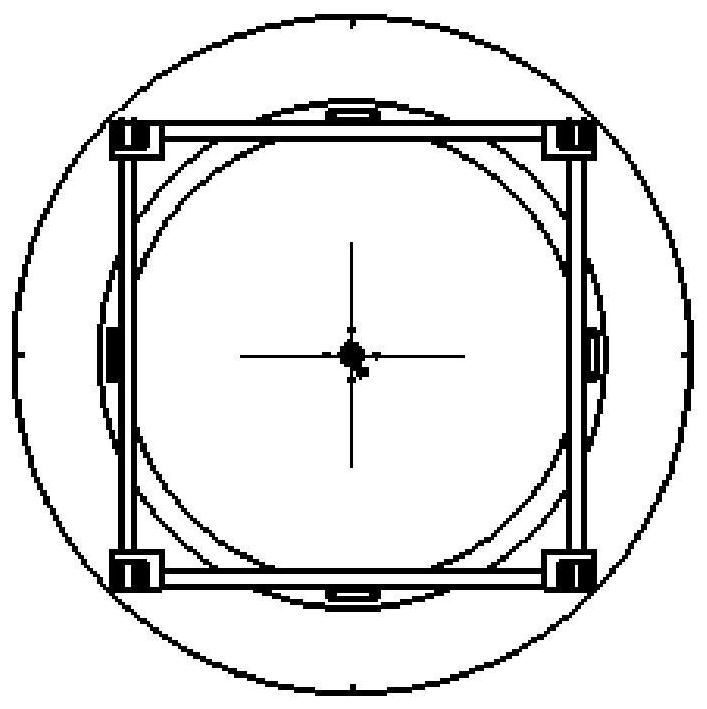

[0049] The invention is used in the overall molding process of the heat-resistant material, and the porosity is filled with resin to form a rigid structure stage, and the size and shape control of the integrally formed heat-resistant structure product is realized by adopting the pneumatic shape dimensioning tooling and vacuum pumping and pressurizing technology.

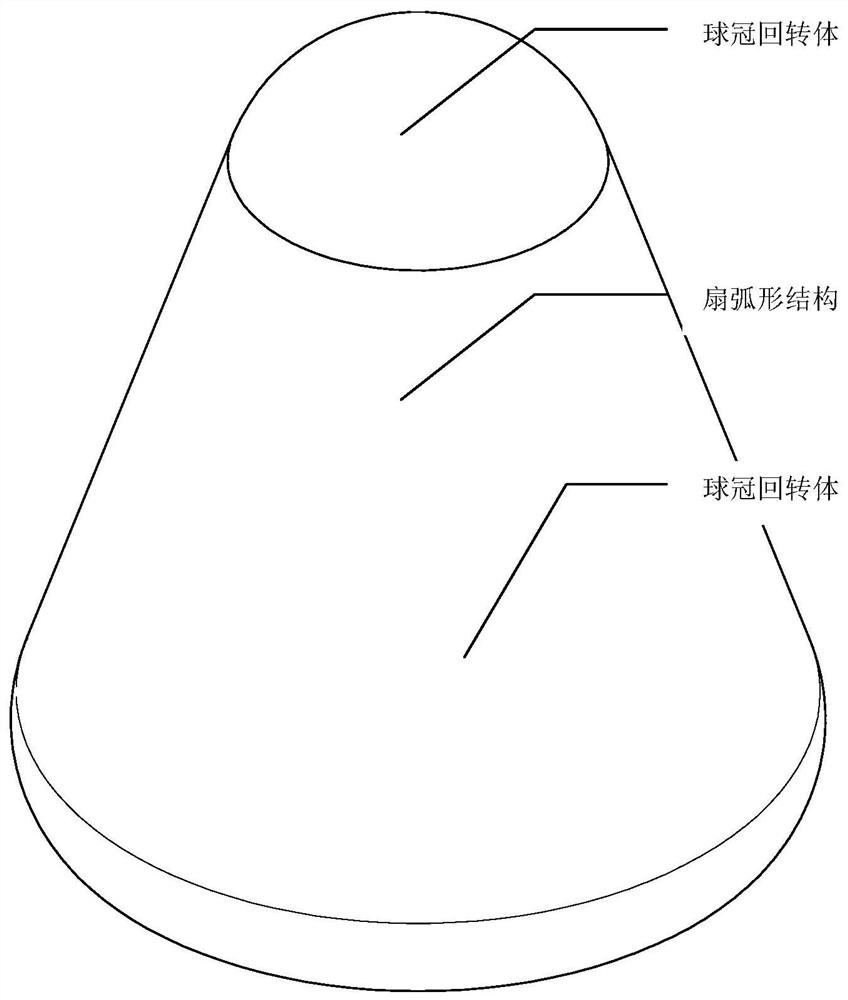

[0050] Hereinafter, the present invention will be described in detail by taking a large-sized, integrally formed heat-proof structure of a reversible spaceship with a low-density fiber three-dimensional structure as a reinforcing phase as an example. The so-called large size means that the maximum projected area of the integrally formed heat-proof structure is greater than 2m 2 Structure.

[0051] Such as figure 1 As shown, the structure of the aerodynamic shape of the exothermi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com