A large aerospace shell sawing equipment and its sawing method

A sawing, large-scale technology, applied in metal sawing equipment, sawing machine devices, sawing machine attachments, etc., to achieve the effect of improving the adaptability of sawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

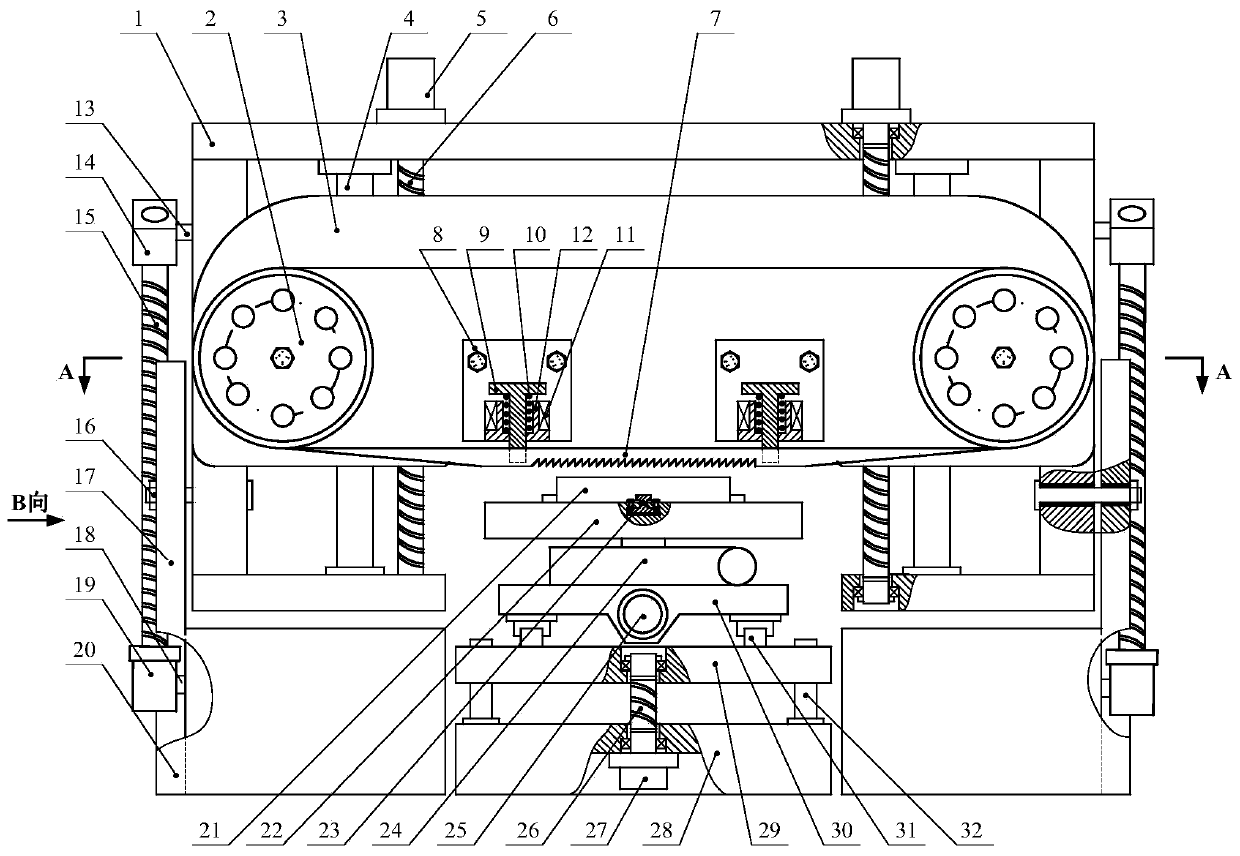

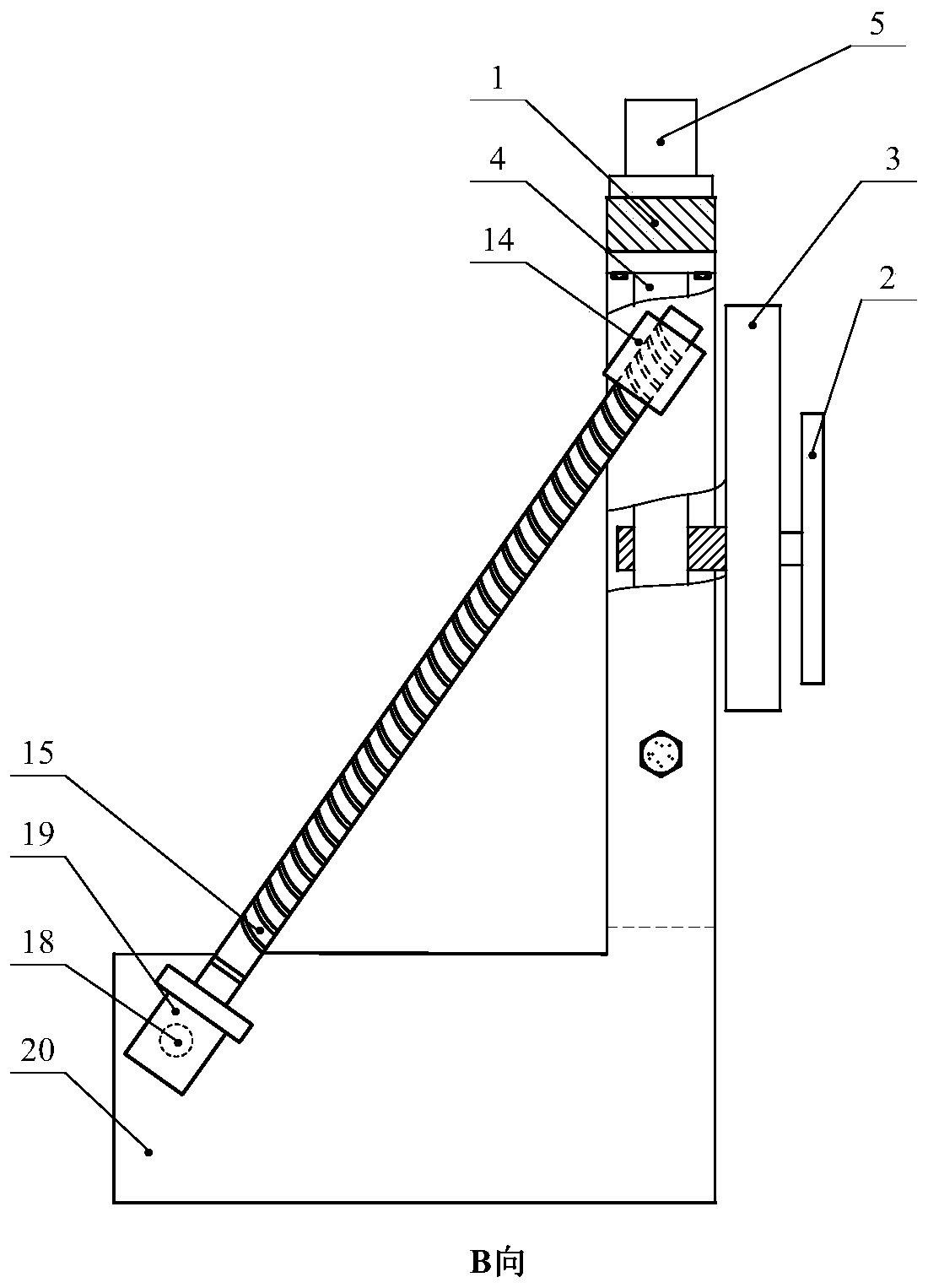

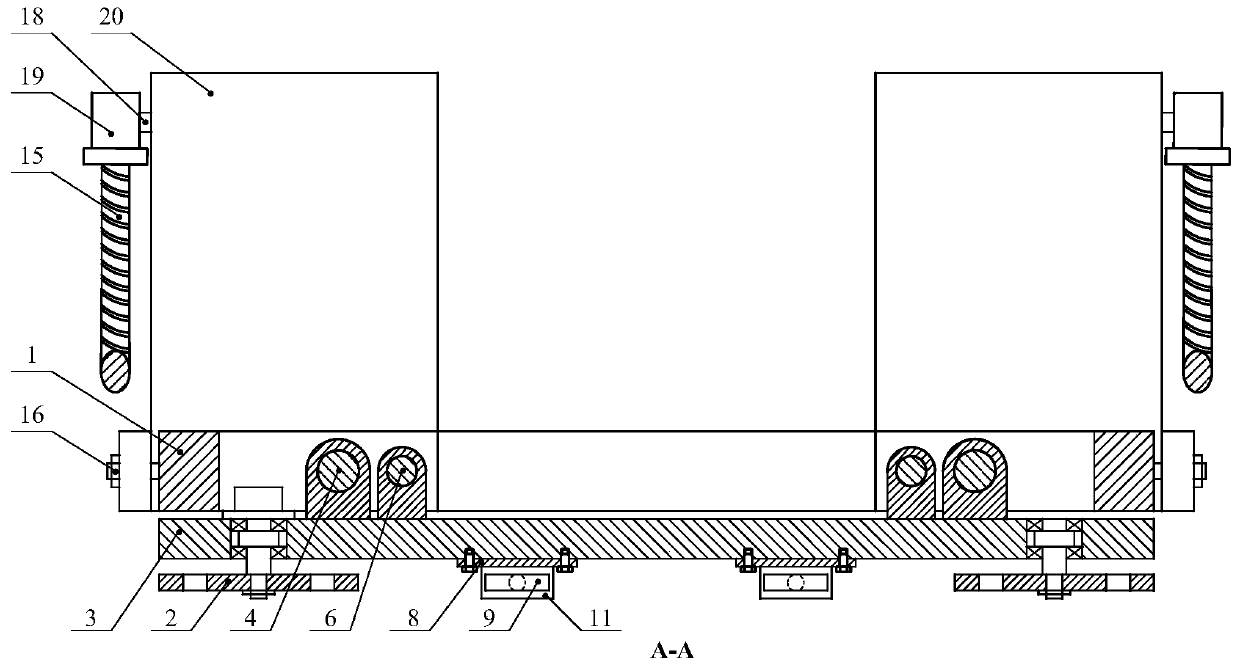

[0031] The present invention will be further described below in conjunction with accompanying drawing.

[0032] like figure 1 , 2 As shown in and 3, the aerospace large-scale shell sawing equipment includes a gantry 1, a guide column 4, a band saw wheel 2, a saw frame 3, a saw band 7, a rotating shaft 16, a bracket 17, a machine base 20, a workbench 22, Clamping slider 23, guide chip breaking assembly, feed drive assembly, tangential adjustment drive assembly, two-axis worktable drive mechanism and pulsation generating assembly 24.

[0033] Two brackets 17 are respectively fixed on two ends of the machine base 20 . The portal frame 1 and two supports 17 form a revolving pair through the rotating shaft 16 . Gantry 1 is positioned directly above machine base 20 . The tangential adjustment drive assembly includes a nut pin 13 , a tangential adjustment nut 14 , a tangential adjustment lead screw 15 , a motor pin 18 and a tangential adjustment motor 19 . Tangential adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com