Coil unloading system and coil unloading method

A steel coil and reel technology, which is applied in the field of oriented silicon steel finishing units, can solve problems such as affecting production efficiency, coil collapse, and falling, and achieve the effect of automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

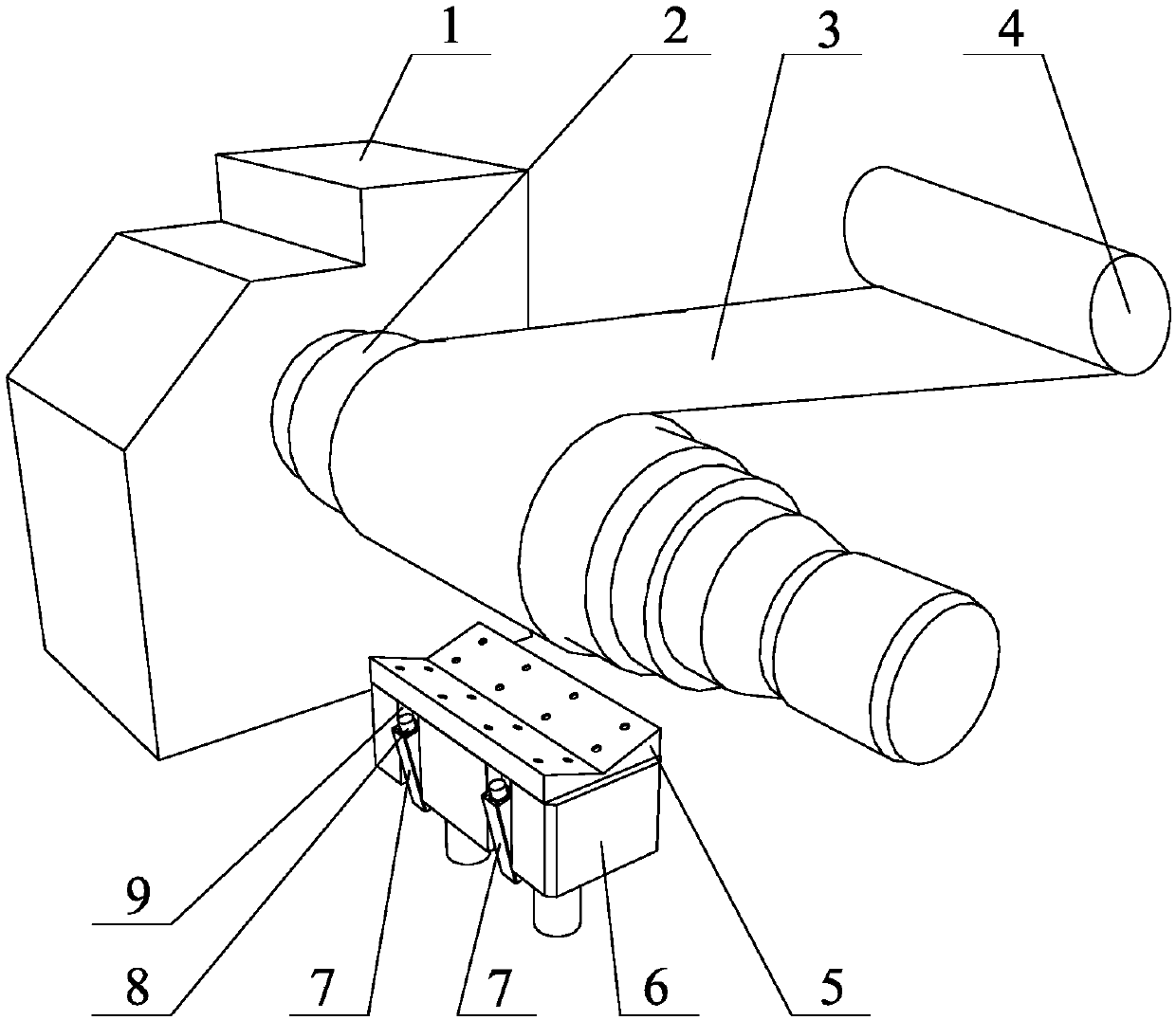

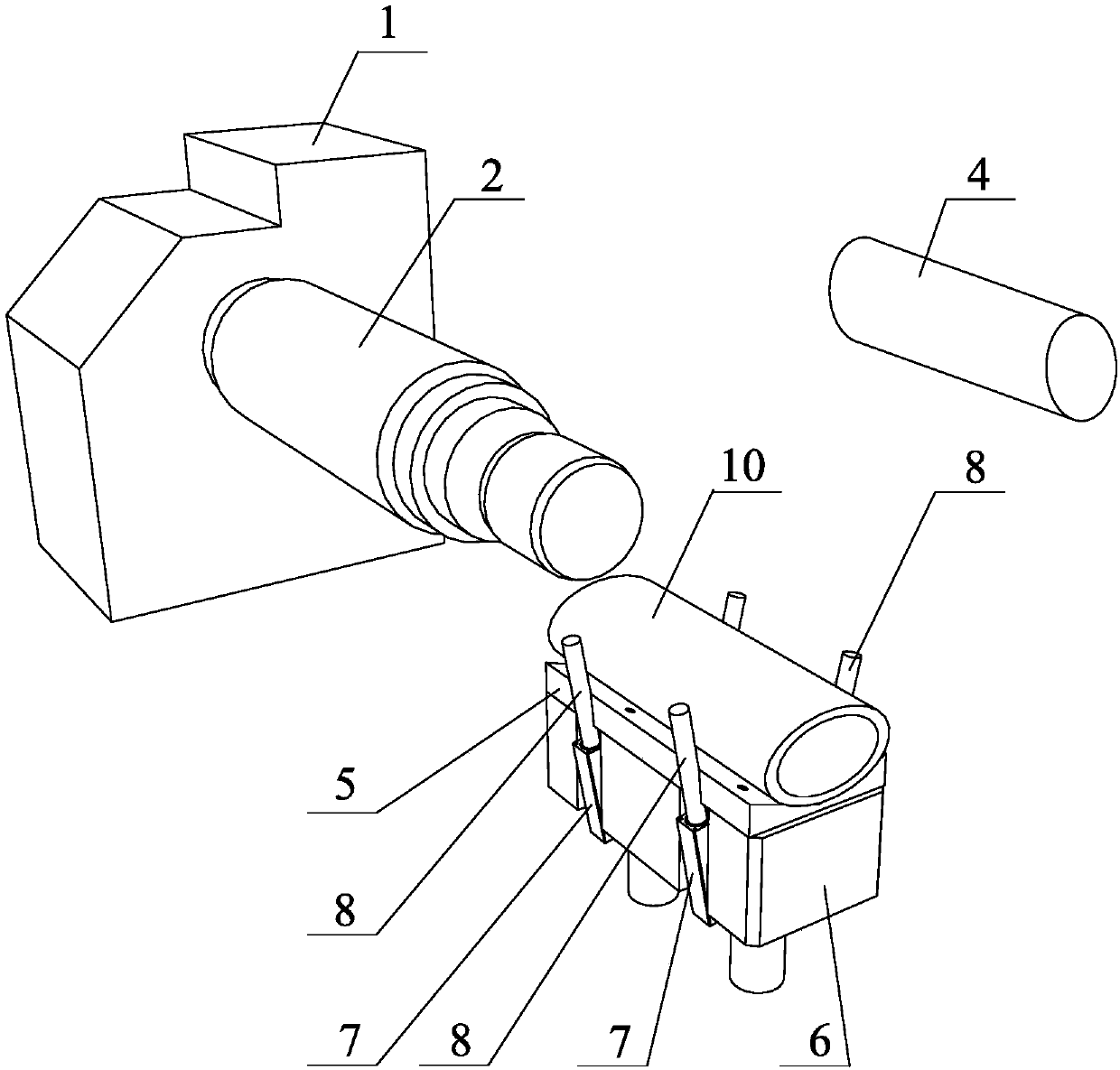

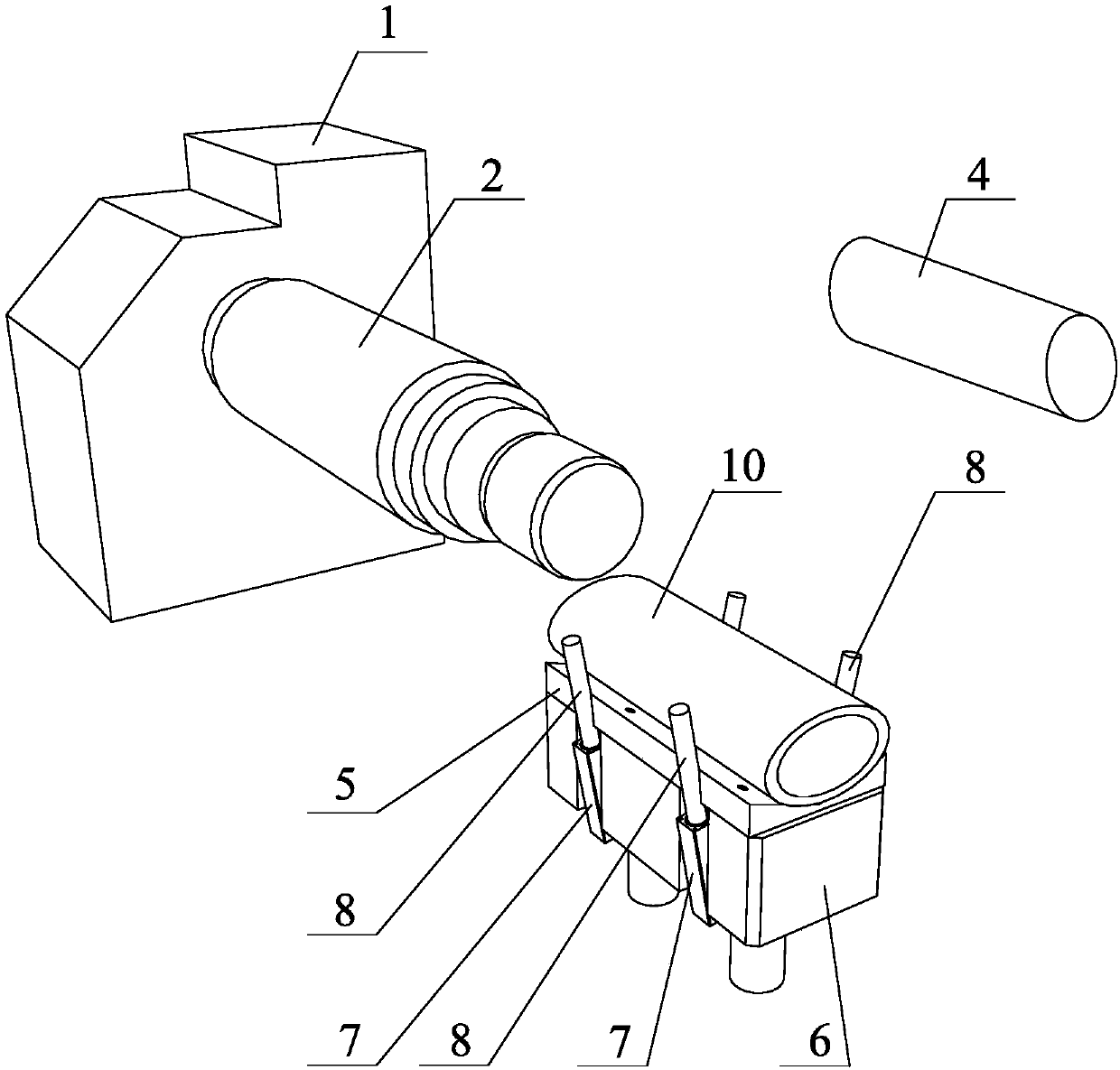

[0027] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

[0028] see figure 1 , figure 2 , the coil unloading system of the present invention is used for unloading the steel coil 10 on the reel 2 of the coiler 1, especially suitable for unloading the steel coil 10 with a small outer diameter. The coil unloading system includes a coil unloading trolley (not shown in the figure), and the coil unloading trolley includes a mobile base 6 and a saddle 5 fixed on the mobile base 6 . Above-mentioned mobile base 6 can move along the axial direction of reel 2, and this function can be realized in many ways, for example, be provided with traveling wheel below mobile base 6, be provided with the track for walking of traveling wheel along the axial direction of reel 2. The saddle 5 is used to accept the steel coil 10. In order to make the coil unloading trolley suitable for steel coils 10 of vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com