Cooking method of automatic cooking utensil

A cooking method and automatic cooking technology, which is applied to cooking utensils, household utensils, kitchen utensils, etc., can solve the problems of uneven heating and mixing of ingredients, bad taste, etc., and achieve the effect of increasing the probability of heating, avoiding the stickiness of ingredients, and promoting heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

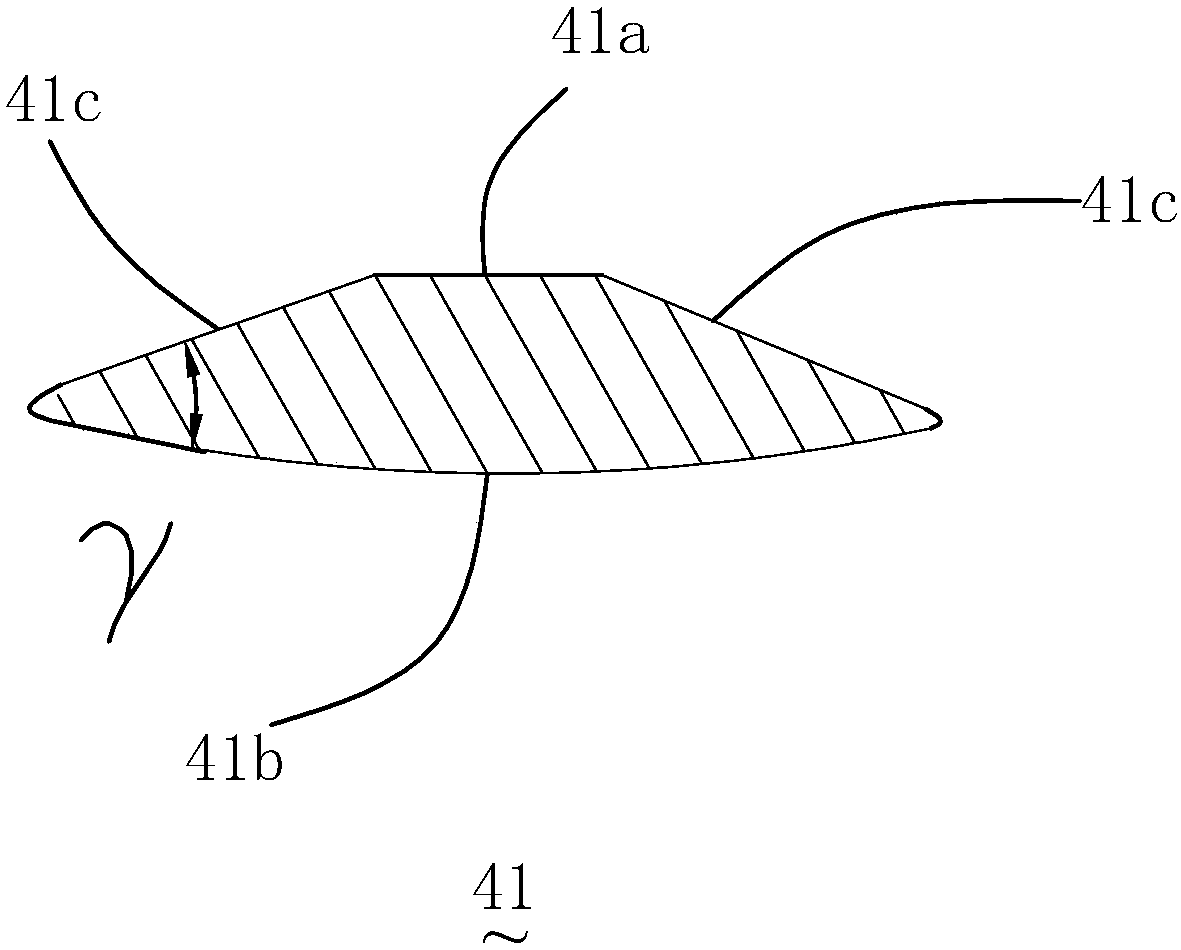

[0033] combine Figures 1 to 4 As shown, in the embodiment of the present invention, the automatic cooking appliance includes a machine base 10, a pot body 20, a pot cover 30, a stirring paddle 40, and a driving device 50 for driving the stirring paddle 40, and the pot body 20 is a rotating Body, the pot body 20 is embedded into the machine base 10, the pot cover 30 is fastened on the pot body 20, the stirring paddle 40 is arranged in the pot body 20 in a laterally swingable manner, and the swing center axis of the stirring paddle 40 is in line with the The central axis of rotation of the pot body 20 is vertical. The cooking utensil also includes a heating device 60 , which may be electromagnetic heating or electric heating tube heating. The shape of the heating device 60 is adapted to the outer wall of the pot body 20 . It can be understood that the stirring paddle 40 can be fixed on the pot cover 30, and when the pot cover 30 is fastened on the pot body 20, the stirring pad...

Embodiment 2

[0068] Different from Embodiment 1, in this embodiment, if Figure 8 As shown, the heating device forms a first heating area S on the pot body. In the preheating stage, the stirring paddle 40 swings at a first deviation angle to make the material deviate from the first heating area, and in the first deviation The angle stops the first time. It can be understood that the first heating area on the pot body is an area corresponding to the shape of the heating device.

[0069] In this way, at least most of the ingredients can be moved to a side other than the first heating area of the pot body 20 by the stirring paddle 40, so that the ingredients and the seasoning are separated. During the stirring process and the process of continuing at this angle, cooking oil and The liquid seasoning can flow back to the central area of the bottom of the pot body 20 through the gap between the stirring paddle 40 and the pot body 20, so that the heat at the bottom of the pot body can be tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com