Support skeleton for adjusting inter-turn resistance of uninsulated superconducting magnet and using method

A technology of superconducting magnets and supporting skeletons, applied in superconducting magnets/coils, magnetic objects, circuits, etc., can solve problems such as damaged strips and inter-turn resistance that cannot be adjusted, and achieve the effect of simple adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

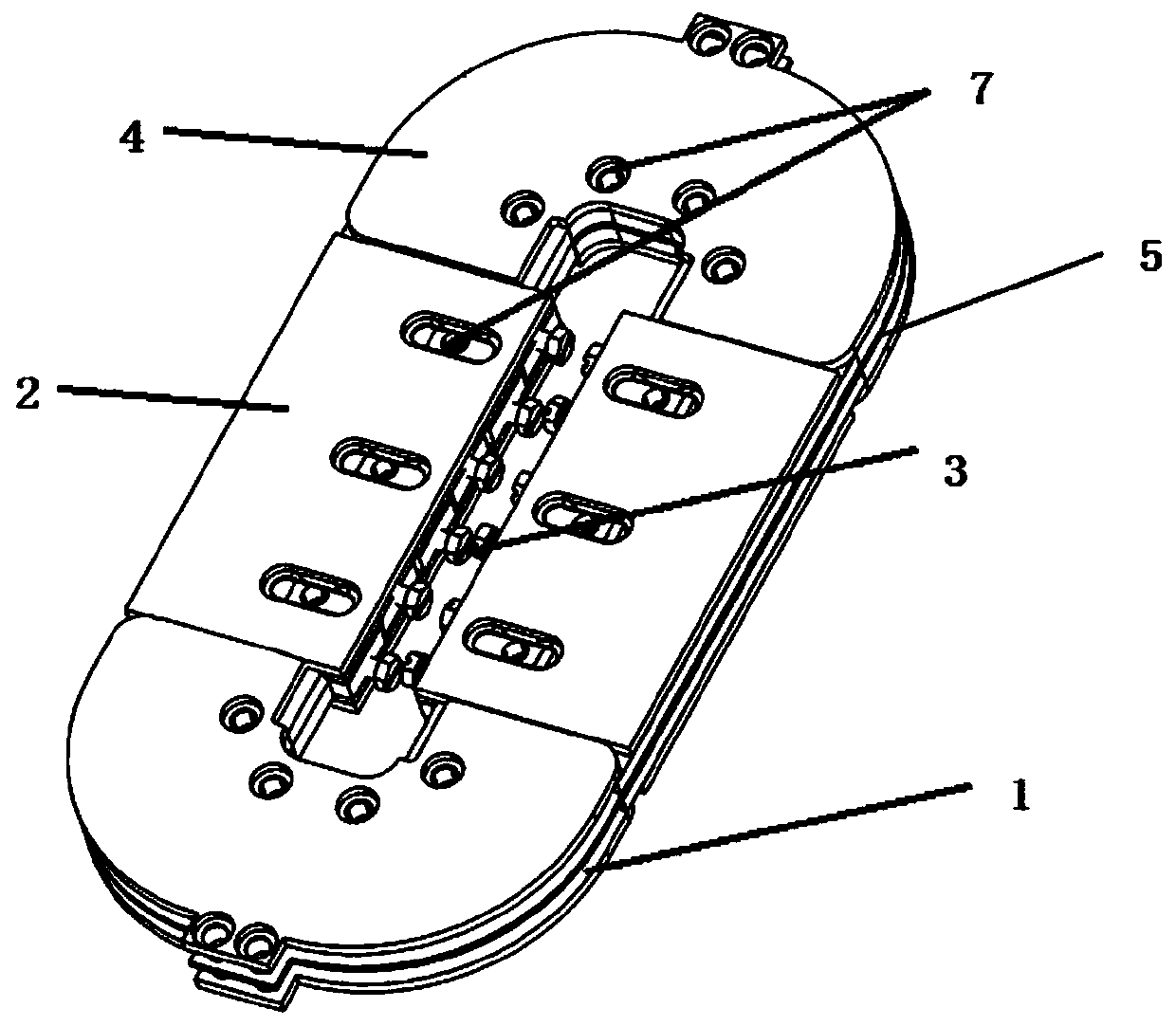

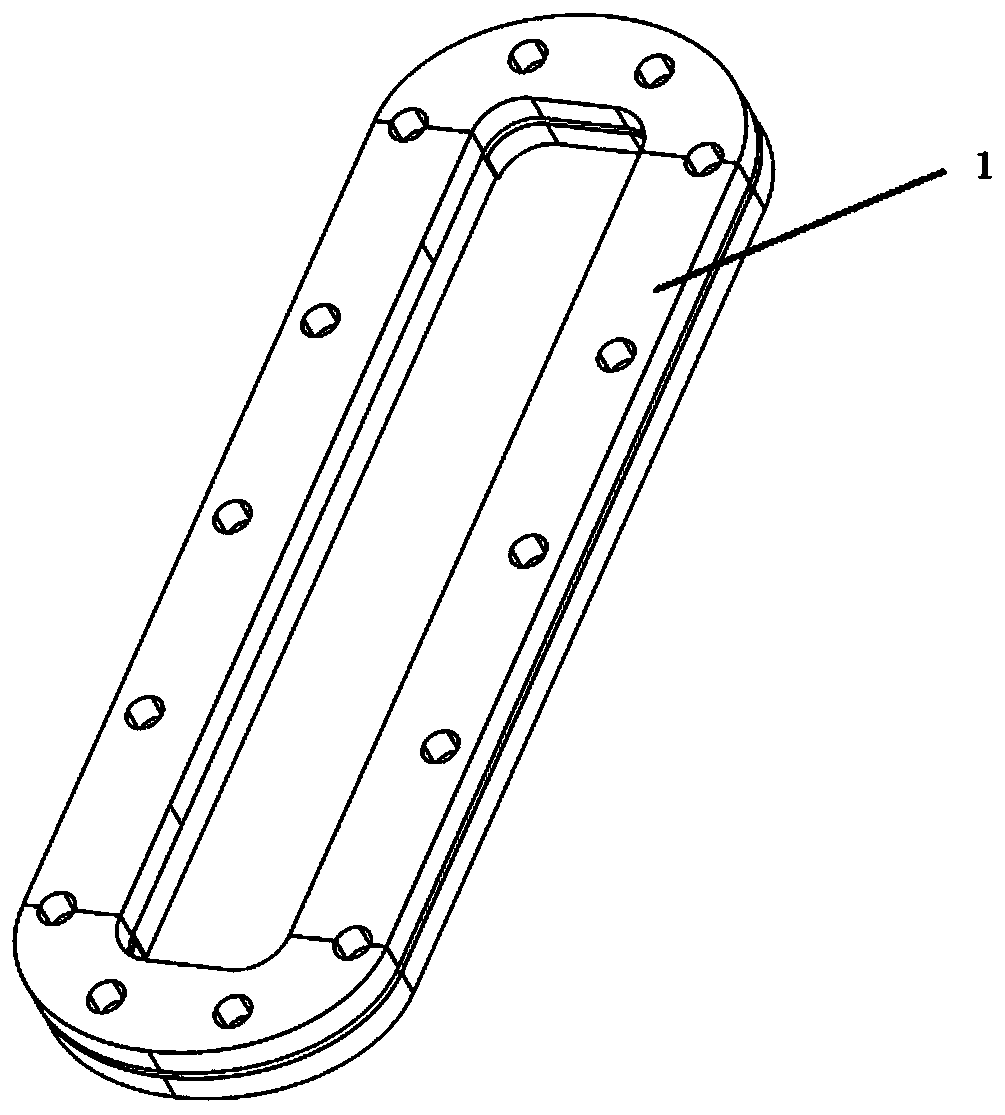

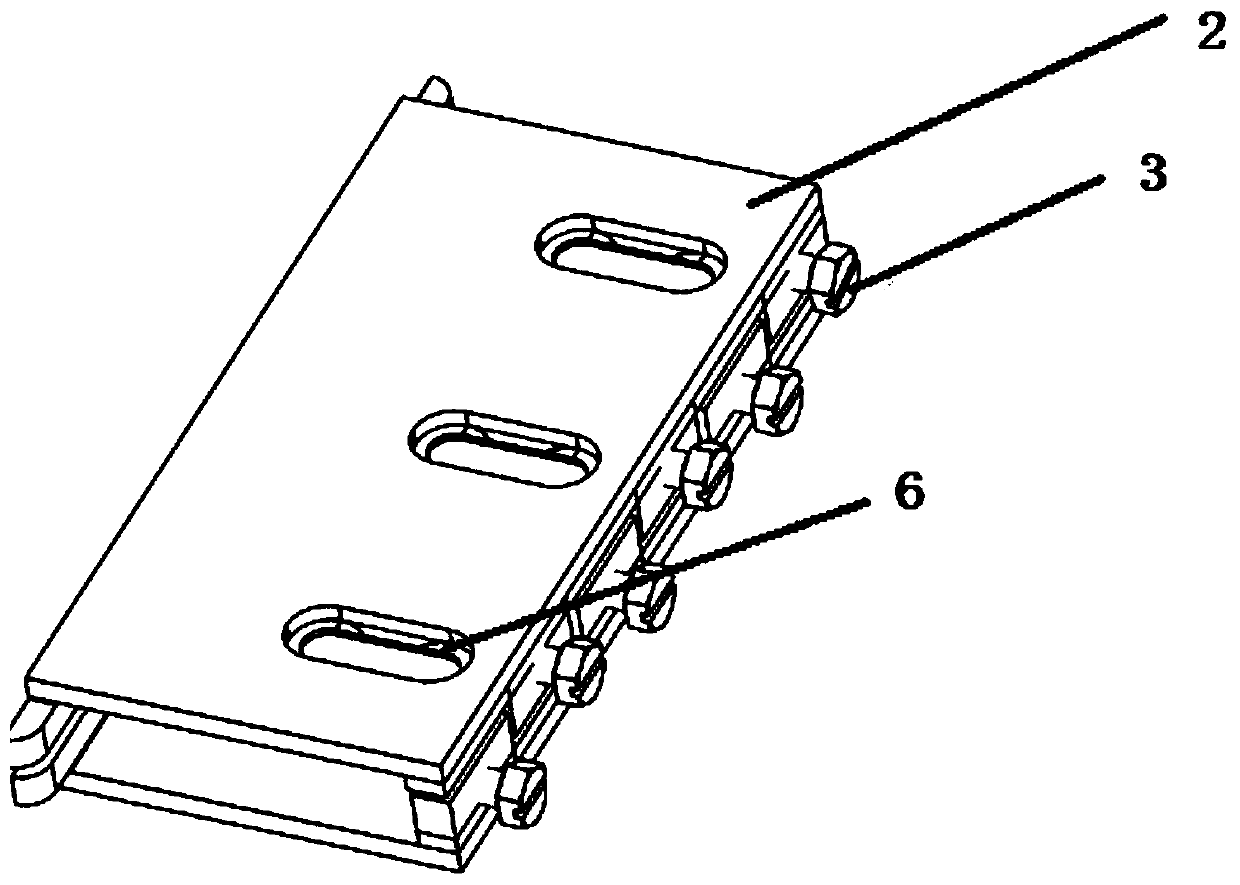

[0038] figure 1 Shown is a schematic diagram of a support skeleton for adjusting the interturn resistance of an uninsulated superconducting magnet for a double pie coil according to a preferred embodiment of the present invention, figure 2 , image 3 , Figure 4 with Figure 5 respectively figure 1 Schematic diagram of the coil bobbins, splints, cover plates, and lanes supporting the bobbin shown.

[0039] In this embodiment, the supporting frame for adjusting the turn-to-turn resistance of a non-insulated superconducting magnet includes a coil frame 1, a splint 2, an adjustment device 3, a cover plate 4, and a lane divider 5; the coil frame 1 is a non-insulated superconducting tape The material wound magnet provides a winding support, and the coil bobbin 1 is a geometrically symmetrical cylinder that runs through the hollow in the axial direction. The shape of the inner side of the cross section of the cylinder is a rounded rectangle, and the shape of the outer side is a...

Embodiment 2

[0049] In this embodiment, the support frame further includes a fixing device.

[0050] Since magnets are generally used in motors, the electromagnetic force of the stator and rotor will interact during operation; and the motor itself may also be directly used in motion scenarios. This is the unavoidable stress on the magnet or supporting frame during operation. In order to prevent the supporting frame or the magnet from being vibrated during operation, causing displacement, quenching or increased flux leakage, etc., preferably, after the assembly of each part of the supporting frame is completed, the fixing device is used to tighten each supporting frame. Solid, such as the connection between the fixed part of the splint 2 and the axial upper and lower surfaces of the coil bobbin 1, and the connection between the cover plate 4 and the axial upper and lower surfaces of the coil bobbin 1.

[0051] Considering the simplicity of the fastening operation and the reliability requir...

Embodiment 3

[0058] Through specific experiments, this embodiment describes in detail the method for using the support skeleton for adjusting the interturn resistance of non-insulated superconducting magnets involved in the present invention, which specifically includes the following steps:

[0059] Step 1, winding the non-insulated superconducting strip around the bobbin 1 to form a magnet;

[0060] Step 2, testing the charging delay of the magnet;

[0061] Step 3, if the charging delay of the magnet is too long, the inter-turn pressure of the coil is too large, use the adjusting device 3 to increase the relative position of the moving part of the splint 2, reduce the extrusion degree of the coil of the magnet, and test again; otherwise, use The adjusting device 3 reduces the relative position of the moving part of the splint 2, increases the extrusion degree of the coil of the magnet, and tests again;

[0062] Step 4: Repeat steps 2 and 3 until the charging delay of the magnet finally m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com