Improved multi-target Jaya algorithm based discrete manufacture workshop production arranging method

A discrete manufacturing workshop, multi-target technology, applied in the field of intelligent manufacturing, can solve the problems of low production efficiency, low accuracy, poor energy saving and emission reduction effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with accompanying drawing, the present invention is further described:

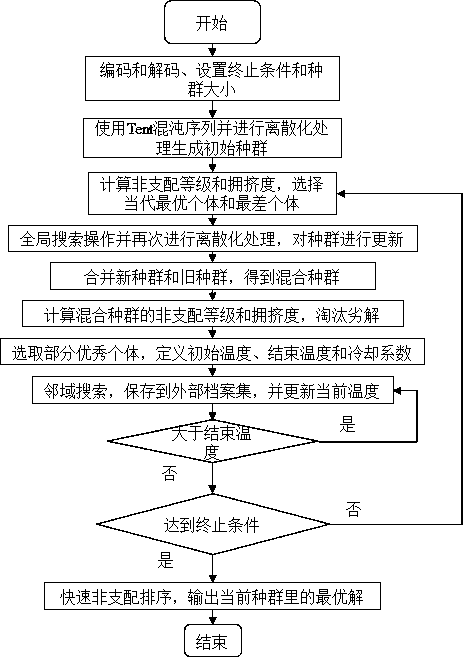

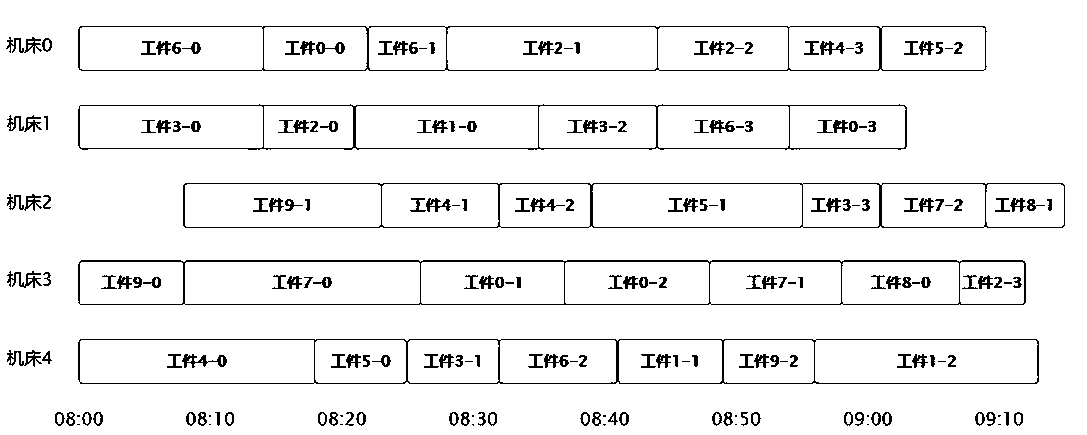

[0066] like Figures 1~8 As shown, the present invention provides a method for scheduling production in a discrete manufacturing workshop based on the improved multi-objective Jaya algorithm, which includes the following steps, as figure 1 shown,

[0067] S1: Monitor the real-time status of the discrete manufacturing workshop through the Internet of Things system and collect data; for example, an IoT system based on RFID technology can be used to monitor the real-time status and process data.

[0068] S2: Preprocess the collected data and capture information about abnormal conditions to obtain effective workshop data.

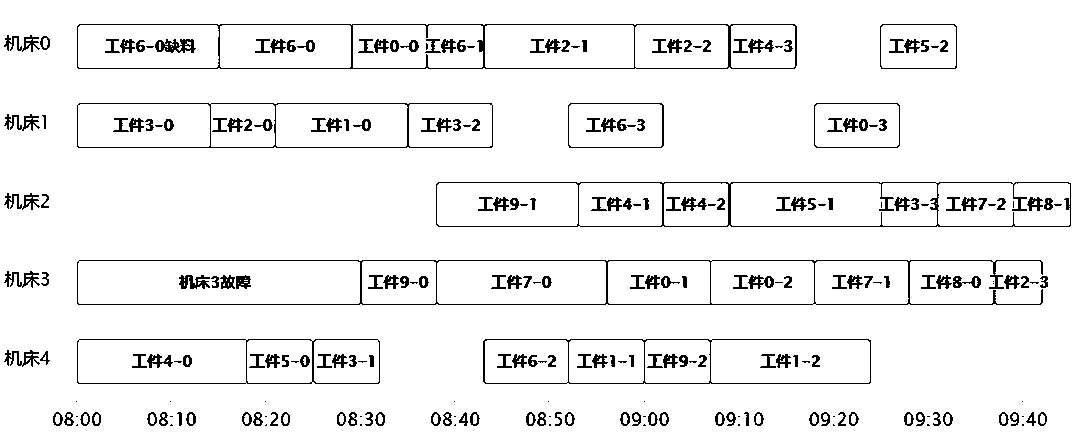

[0069] S3: Use the abnormal event database to match the effective workshop data, analyze and judge whether the abnormal situation affects the processing time of the workpiece, and if the abnormal situation affects the processing time of the workpiece, input th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com