An automatic detection method of ultrasonic c-scanning based on industrial robot

An industrial robot, automatic detection technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. Frequent pose adjustment and other problems, to achieve the effect of simplifying the motion path, high detection efficiency, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

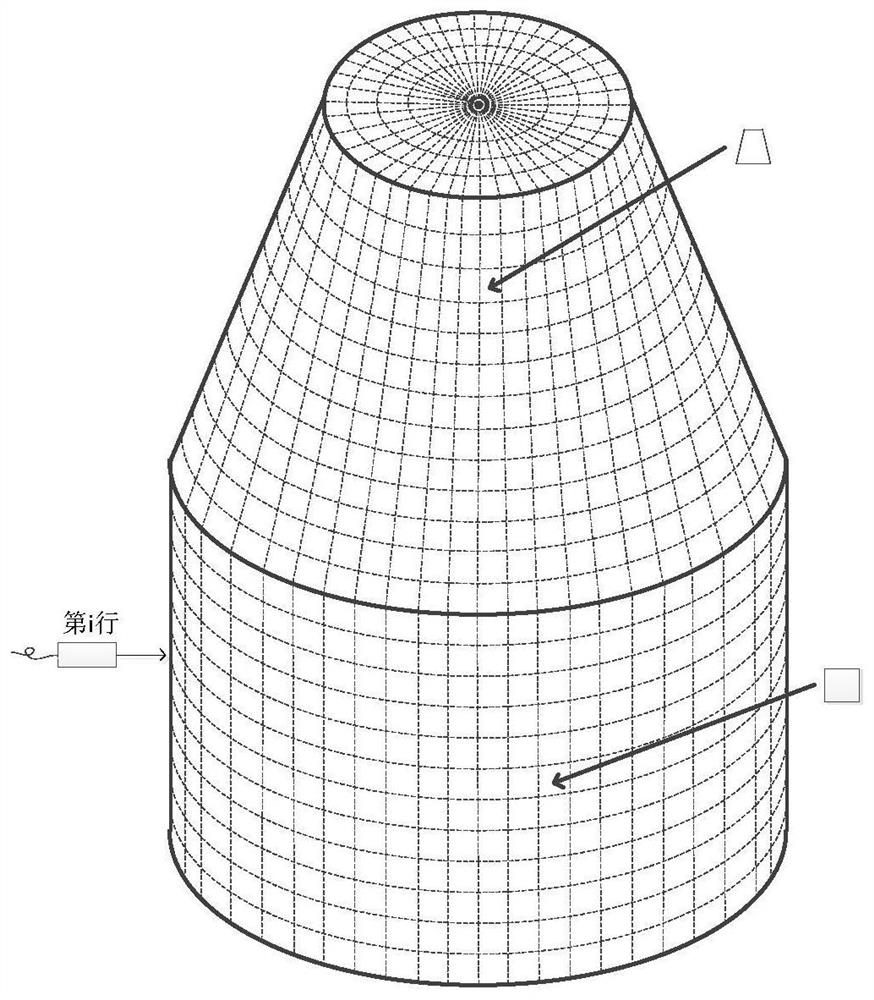

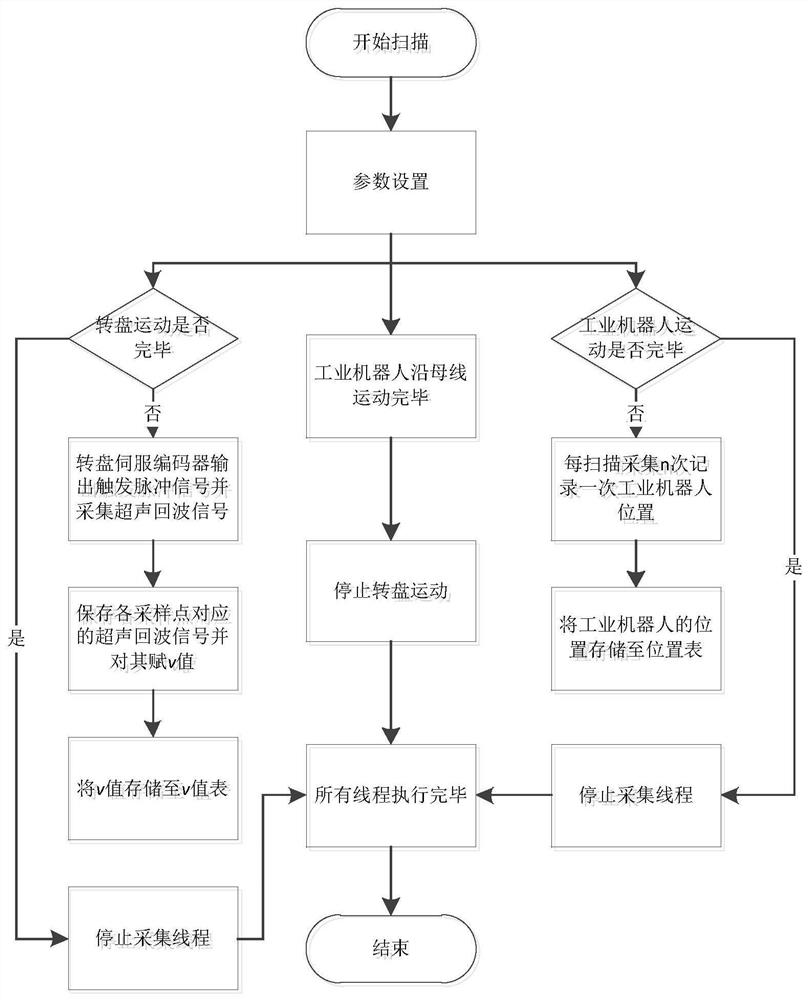

[0043] A kind of ultrasonic C-scan automatic detection method based on industrial robot, comprises the following steps:

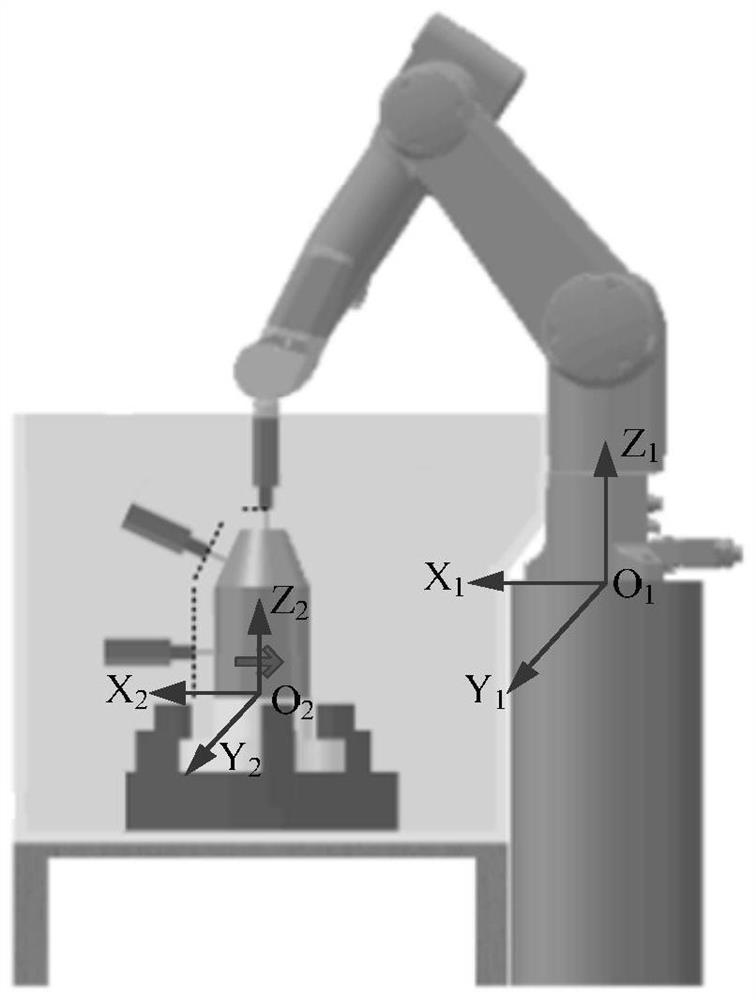

[0044] Step S1. In order to realize accurate path planning based on the CAD model of the workpiece, and facilitate the accurate correspondence between the ultrasonic signal and the spatial position of the C-scan 3D imaging model during the scanning process, it is necessary to use a special teaching pendant for industrial robots or other auxiliary methods to define the reference of the detection system Coordinate System. Place the workpiece to be measured at the center of the turntable, teach the world coordinate system and the reference coordinate system, as follows figure 1 As shown, the world coordinate system is fixed on the base of the industrial robot manipulator and fixed with the installation of the manipulator. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com