Pneumatic capillary tube clamping device

A technology of clamping device and capillary tube, which is applied in the direction of measuring device, instrument, liquid/fluid solid measurement, etc., can solve the problems of low efficiency, cumbersome loading and unloading, etc., and achieve the effect of efficient operation, labor liberation, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

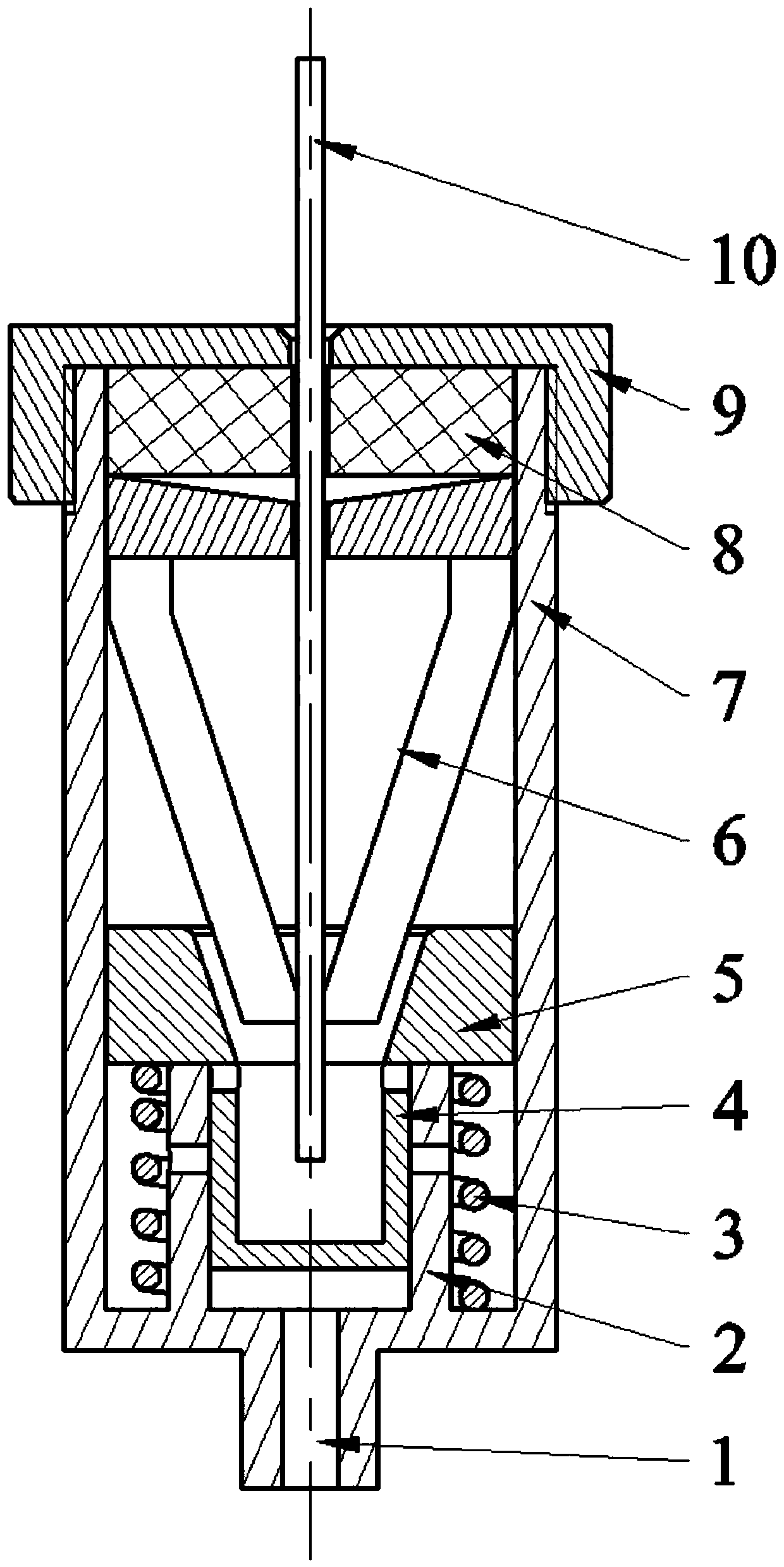

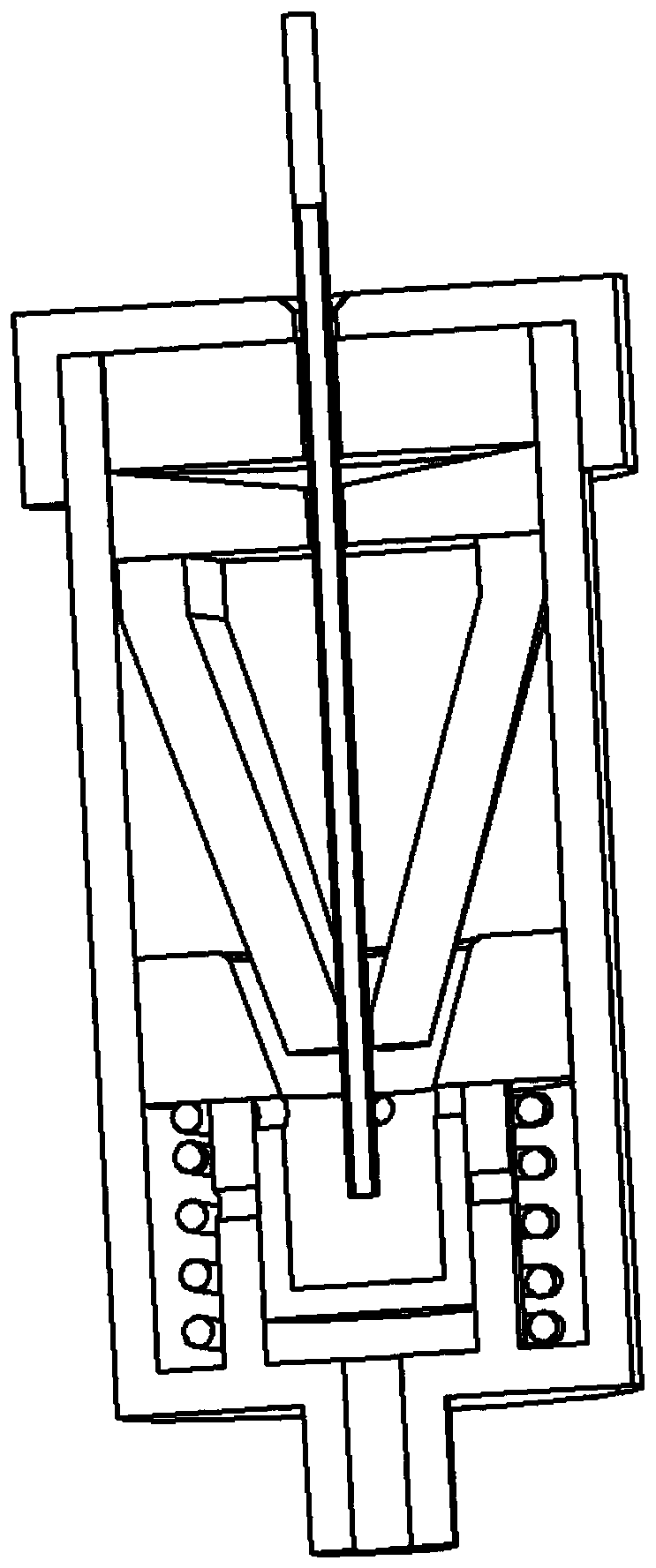

[0025] like Figure 1-2 As shown, a pneumatic capillary clamping device includes a cylinder 7 , a piston 4 , a cylinder head 9 , a spring 3 , a clamping seal 6 and a rubber ring 8 .

[0026] The cylinder barrel 7 is a cylindrical structure, and one end has an external thread to cooperate with the internal thread of the cylinder head 9 to lock; the other end is an air inlet 1, which communicates with a compressed air source. The inner air inlet end of the cylinder 7 is provided with a cylinder 2 communicated with the air inlet 1, the cylinder 2 is tubular, the bottom of the cylinder 2 is integrated with the bottom of the cylinder 7, and the side wall of the cylinder 2 is provided with at least one through hole.

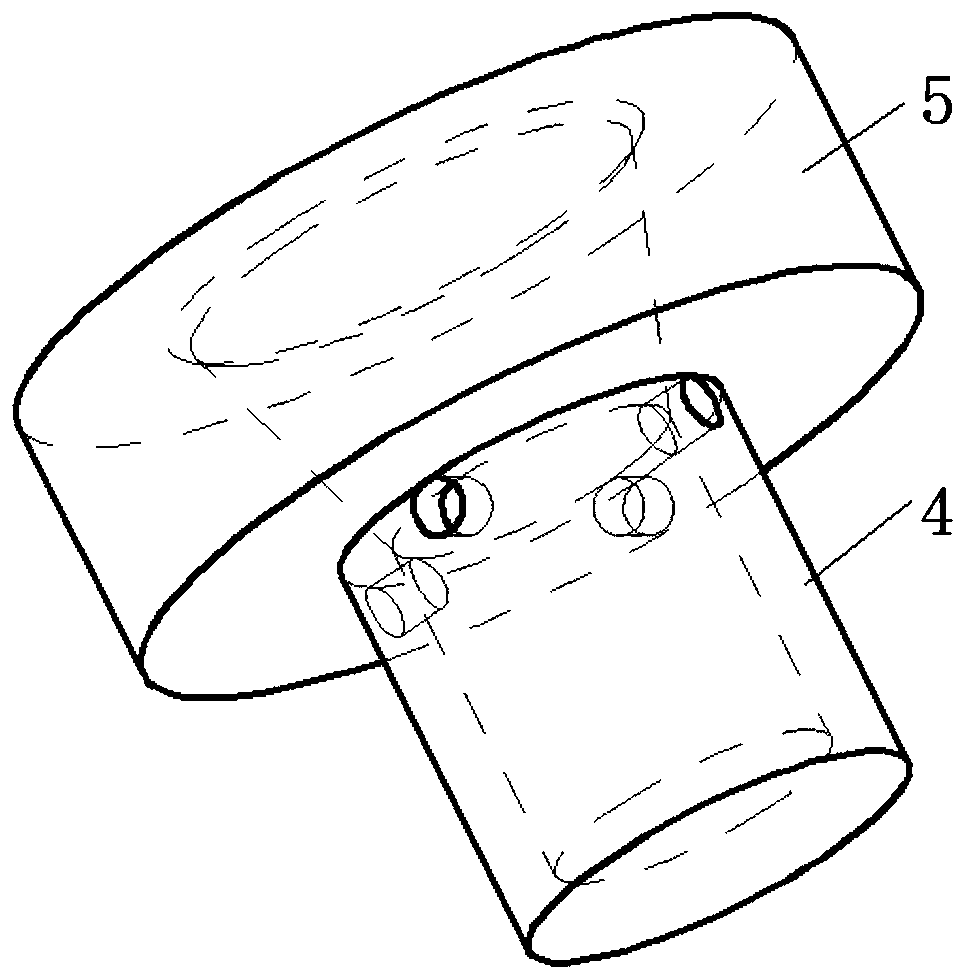

[0027] The piston 4 is installed in the cylinder 2. The outer diameter of the piston 4 is matched with the inner diameter of the cyli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap