Underground sewage pipeline health detection device and installation method of detection device

A technology for health detection and sewage pipelines, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of fiber waste, long fiber length, etc., to reduce the length of use, save costs, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

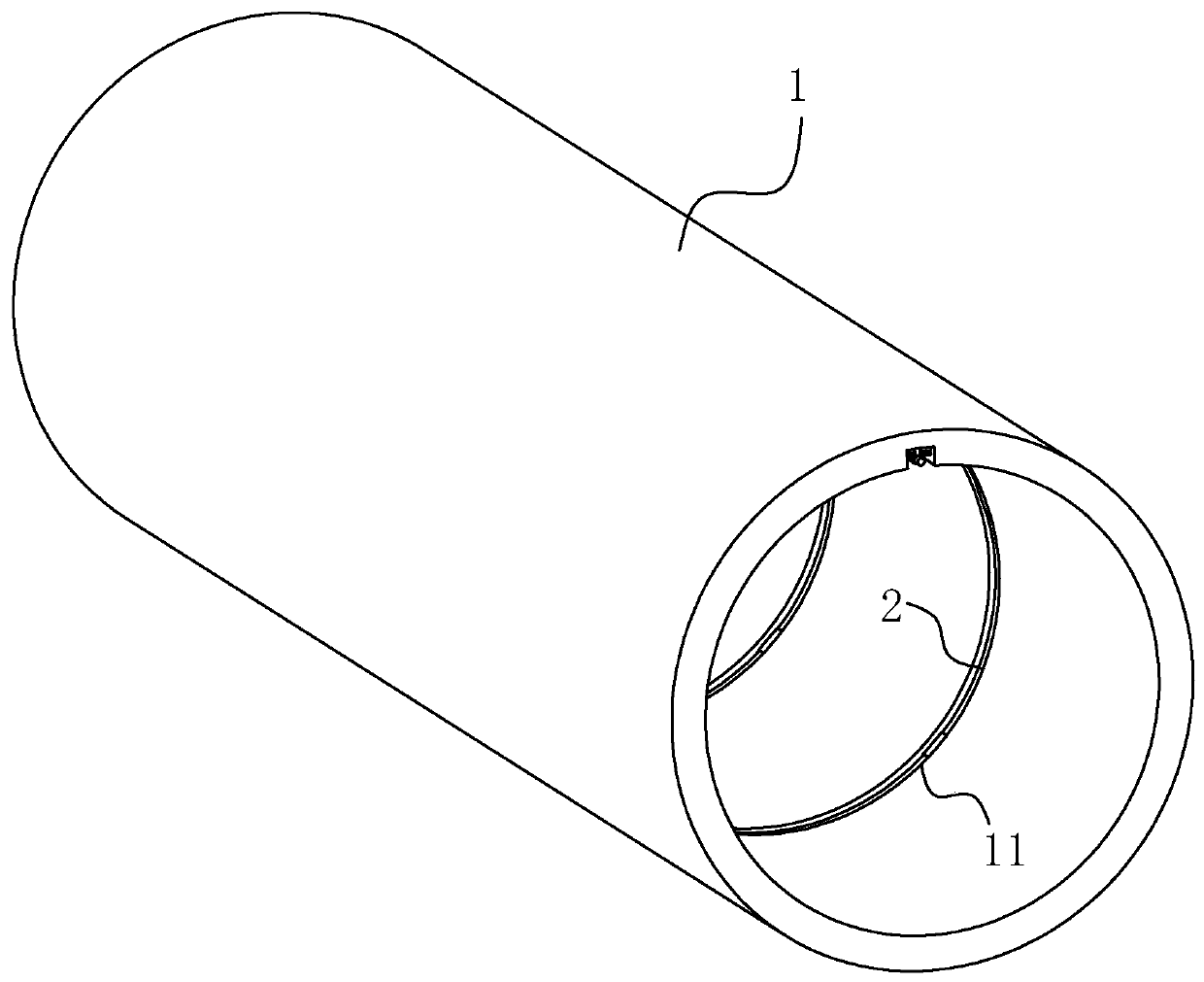

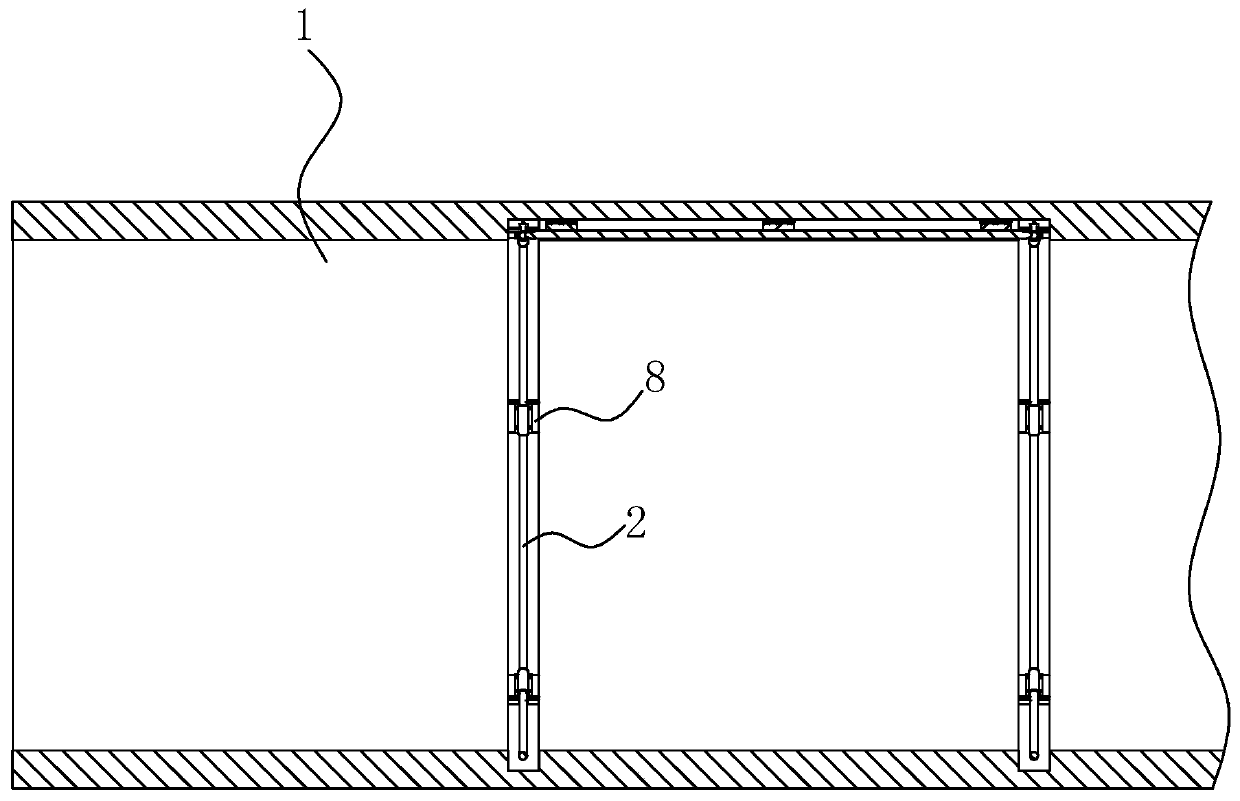

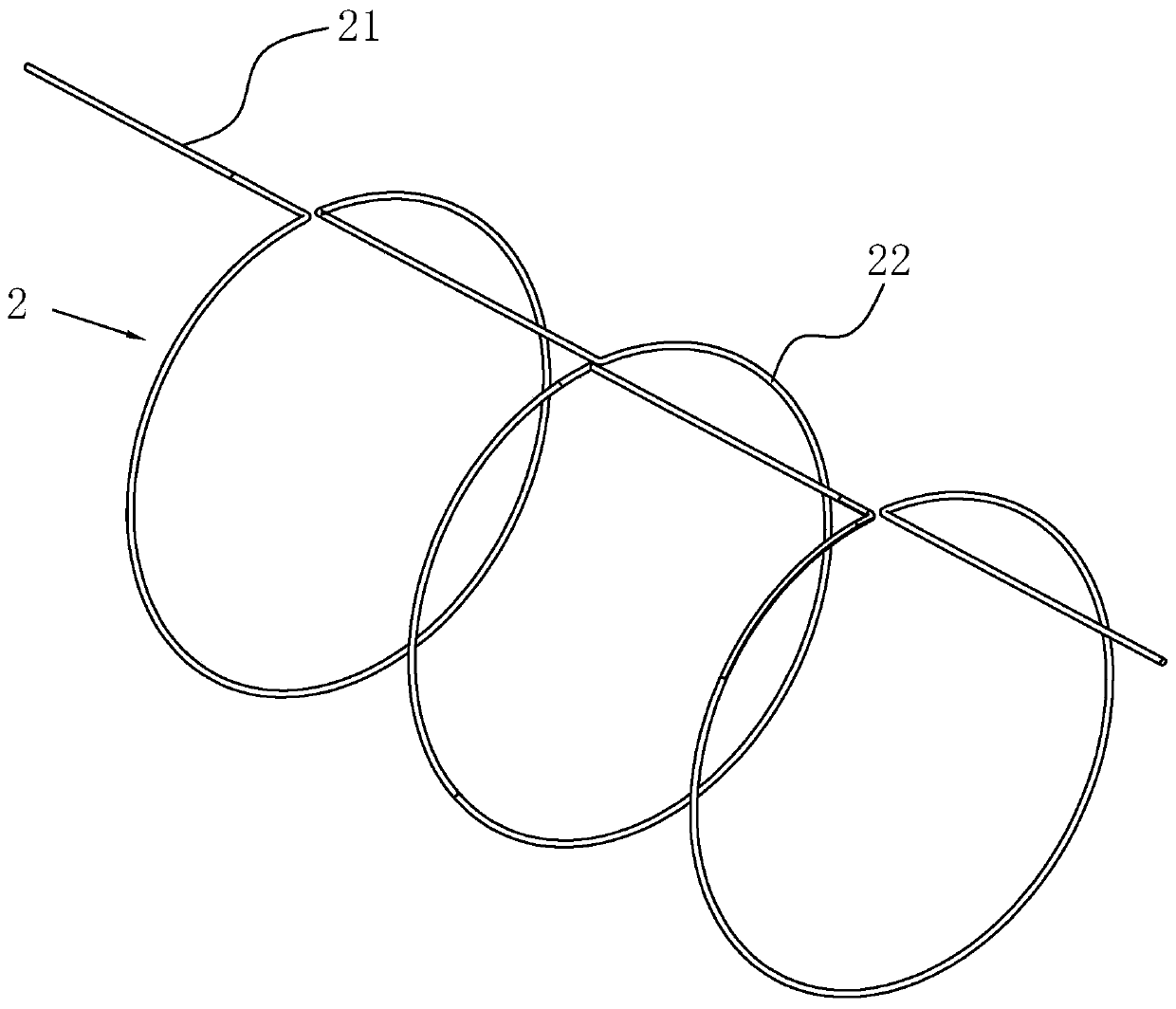

[0044] refer to figure 1 as well as figure 2 , is a health detection device for an underground sewage pipeline 1 disclosed by the present invention, comprising a detection optical cable 2 laid on the pipeline 1 along the length direction of the pipeline 1, referring to image 3The detection optical cable 2 is composed of an axial section 21 and a circumferential section 22 at intervals. The interval between the axial section 21 and the circumferential section 22 is determined according to the inner diameter of the pipe 1. If the inner diameter of the pipe 1 is small, all of them are arranged in a straight line. On the pipeline 1, there is a fixing device for fixing the detection optical cable 2 on the pipeline 1. During detection, the axial section 21 detects the data in the axial direction of the pipeline 1, and the circumferential section 22 detects the data in the circumferential direction. When laying, the straight section and the circumferential section 22 are combined ...

Embodiment 2

[0052] A method for installing a detection device, comprising the following steps:

[0053] Step S1: Line setting, first use the ink cartridge to draw the line and put the line on the surface of the pipeline 1 to draw the planned laying line. The line is kept straight along the axial direction of the pipeline 1, and the line is guaranteed to be circular along the circumferential direction. Use ink cartridges The way of drawing the line can roughly plan the direction of the detection optical cable 2 and improve the accuracy in the laying process.

[0054] In step S1, for the pipeline 1 laid by the open cut method, the detection optical cable 2 is arranged on the outer wall of the pipeline 1; for the pipeline 1 laid by the underground excavation method, the detection optical cable 2 is arranged on the inner wall of the pipeline 1, according to specific construction conditions Selecting the laying position of the detection optical cable 2 is not only convenient for operation, but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com