An anti-freeze pullout device and its construction method

A freeze-pulling and square-shaped technology, applied in infrastructure engineering, construction, etc., can solve the problems of high construction cost, insufficient anti-freeze-pulling ability, long construction period of anti-freeze-pulling foundation, etc. The effect of improving the side friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

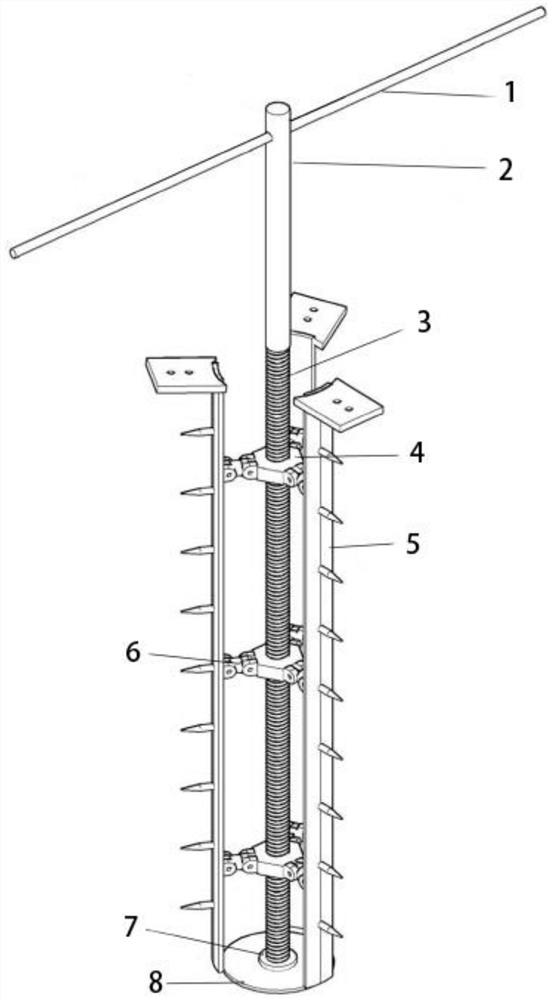

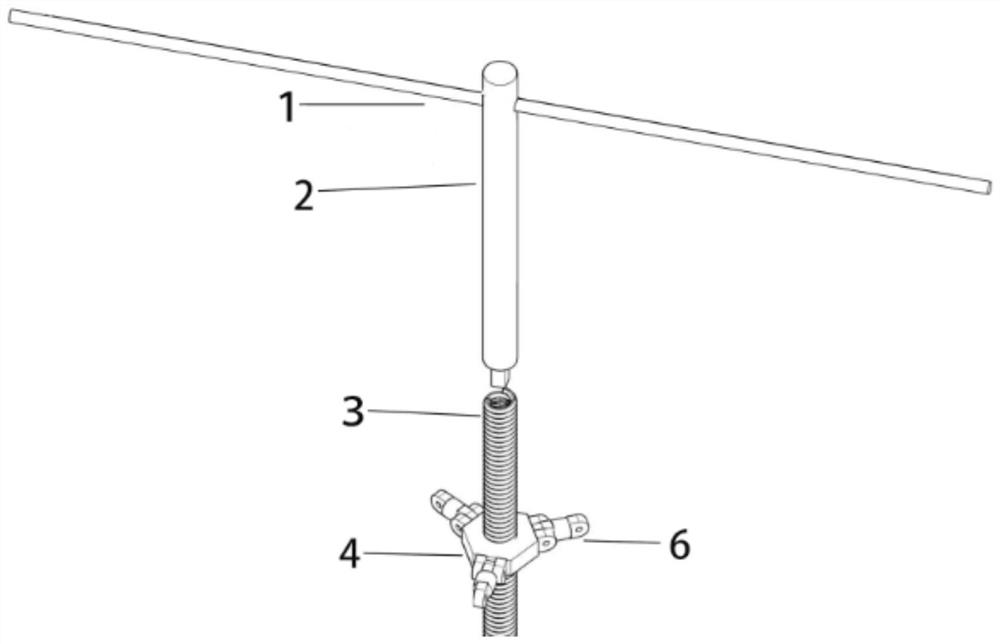

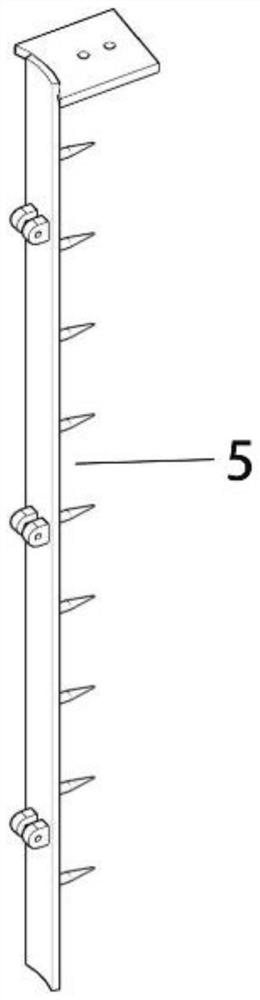

[0030] Below in conjunction with accompanying drawing and further illustrate technical scheme of the present invention by specific embodiment:

[0031] Chassis 8, the chassis is a round steel plate, which is placed horizontally at the bottom of the borehole. The diameter of the chassis should be smaller than the diameter of the push pin plate when it is in the open state, and the thickness of the chassis is generally not less than 30mm to ensure that the chassis has a certain quality, so that the whole device can be stabilized, and the foundation screw can be righted to make the main body of the device in a vertical state .

[0032] Thrust bearing 7, the thrust bearing is a cast boss circular seat bearing, which is connected to the chassis by bolts, and it is interference-jointed with the unthreaded part of the lower part of the screw rod, so that the screw rod forms a whole with the chassis under the action of the thrust bearing, The thrust bearing can play a role in limitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com