Diamond cutting blade experiment device

A technology of diamond cutting and experimental equipment, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of unsatisfactory enterprises, unstable data due to human factors, poor working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

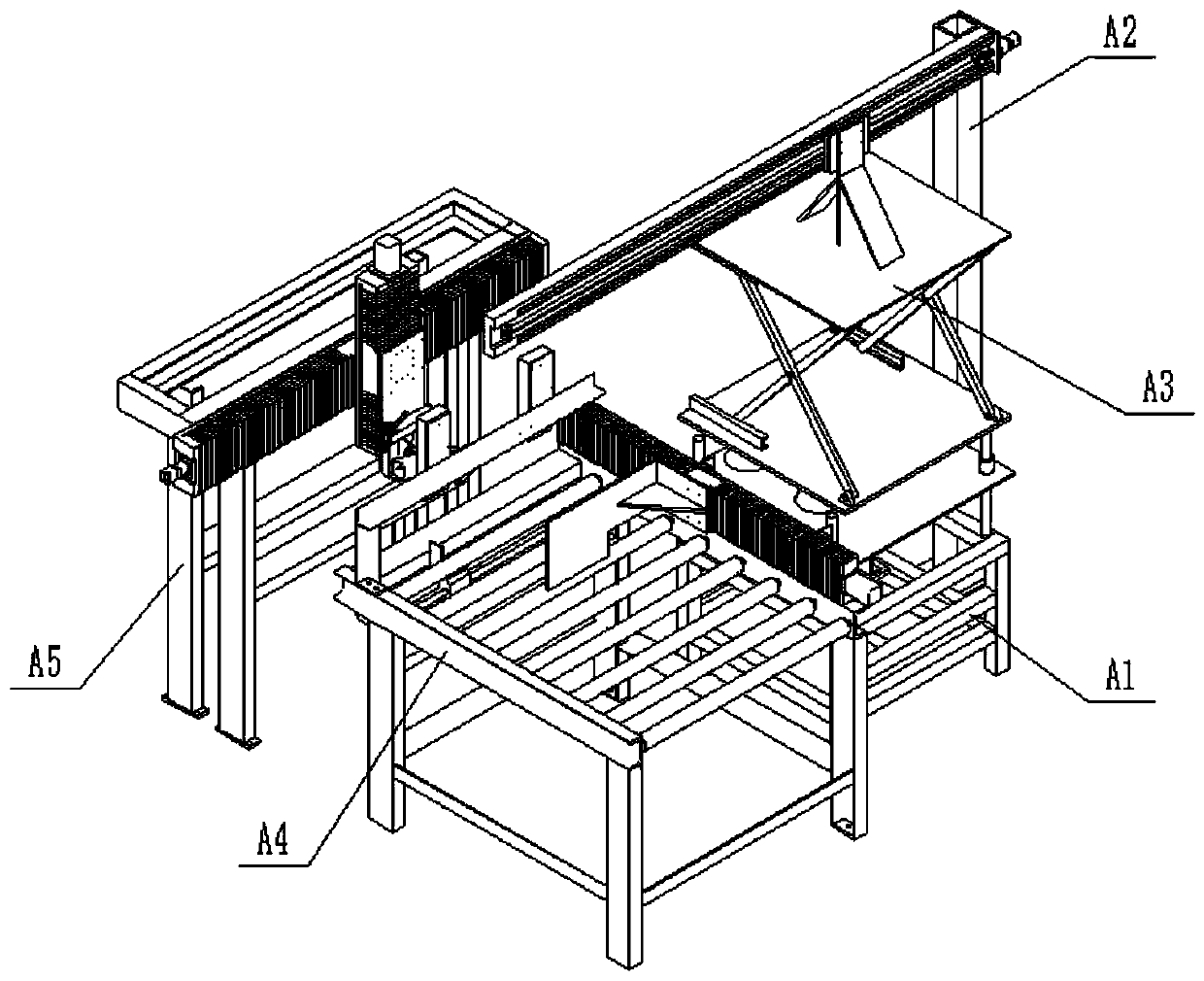

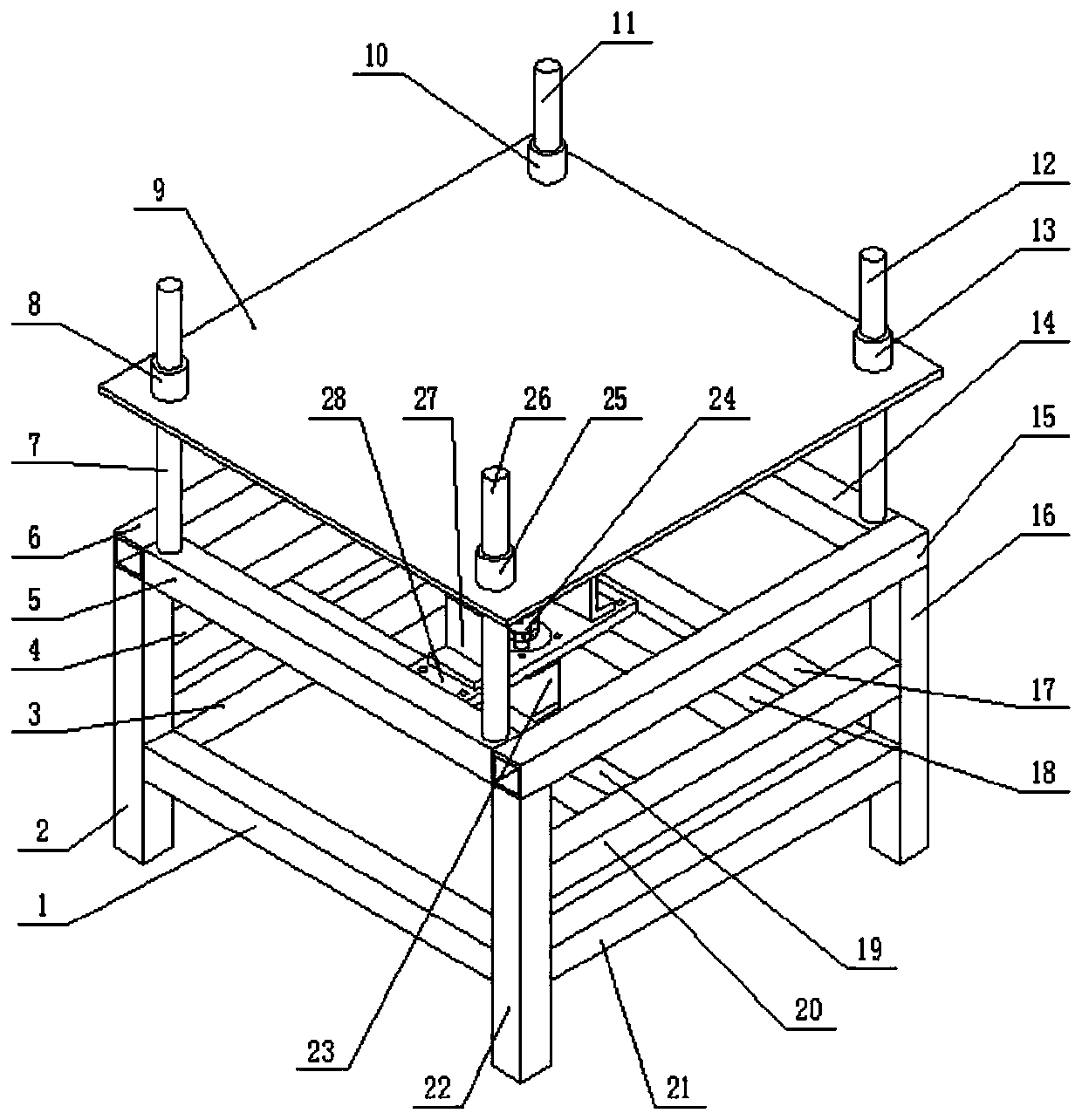

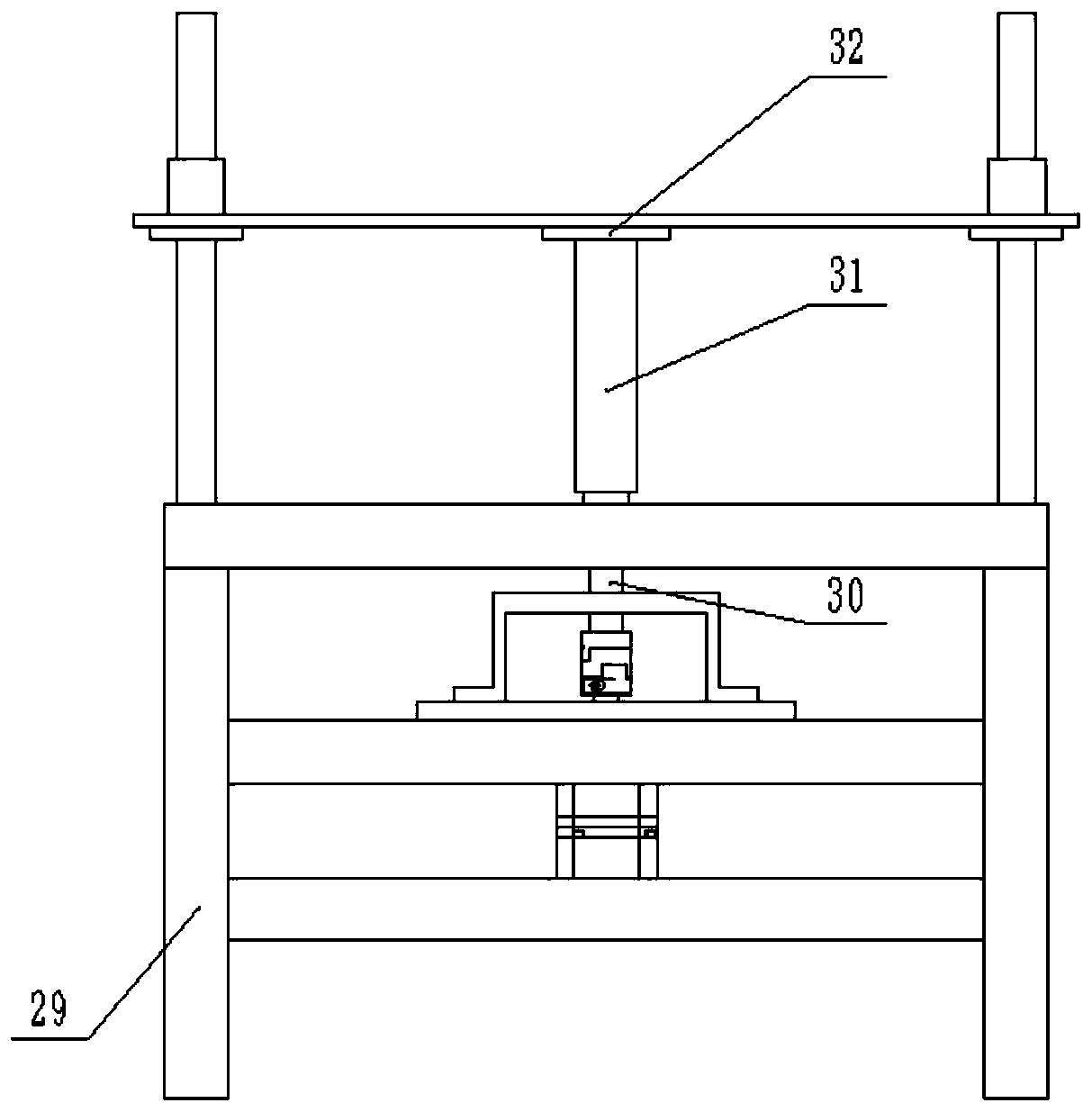

[0041] see Figure 1 to Figure 15 .

[0042] The automatic feeding action of material cutting is completed by material cutting lifting support part A1, material cutting automatic feeding support part A2, and scissor lift platform part A3. At first a certain amount of cutting material is put on the discharge plate 9 of the material lifting bracket part A1 manually, and now the lifting screw 30 is in the longest state stretching into the piston part 31. Then the cylinder 71 in the scissor lift platform part A3 retracts, so that 4 pneumatic suction cups 63, 65, 67, 68 contact with the cut material placed on the topmost on the discharge plate 9, and now 4 pneumatic suction cups 63, 65, 67, 68 work to absorb cutting material. Cylinder 71 stretches out then, makes 4 pneumatic suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com