Solid-wood five-axis processing center

A five-axis machining center and solid wood technology, applied in wood processing equipment, manufacturing tools, special forming/shaping machines, etc., can solve problems that affect production efficiency, high labor costs, and high risks, and achieve production efficiency and automation. High efficiency, safe and efficient processing, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

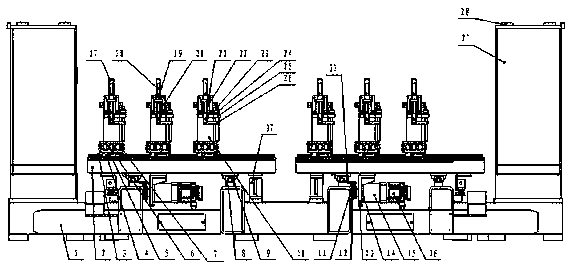

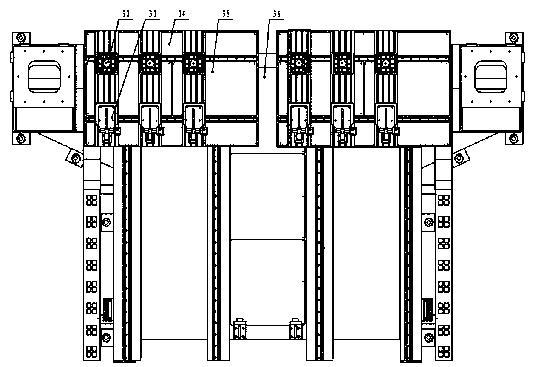

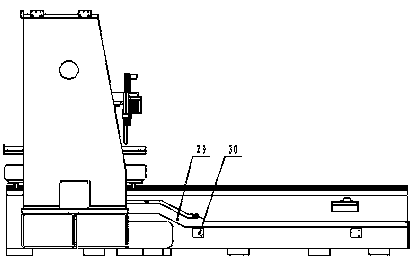

[0050] Example 1: A solid wood five-axis machining center with a structure such as figure 1 Shown; a solid wood five-axis machining center, including a bed part, a crossbeam part, a cross slide part, a Z slide part, a five-axis head part and an automatic feeding part, the bed part is placed on the ground; the crossbeam Part of it is connected with the upper end of the column 27 of the bed part through the beam 38; the cross slide part is slidingly connected with the third guide rail 46 of the cross beam part through the third guide rail slider 88; the Z slide part is connected through the first The four-rail slider 87 is slidingly connected with the fourth guide rail 55 of the cross slide part; the five-axis head part is connected with the Z slide plate 81 of the Z slide part through the C-axis reducer flange 92; The material part is installed on the front end of the bed 1 of the bed part through the feeding bracket 131 .

[0051] Wherein, the bed part includes a bed 1 and a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap