Efficient multi-scale recognizing method for milling tool injuries

An identification method and damage identification technology, which is applied to metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problem of not considering the multi-scale problem of milling cutter damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

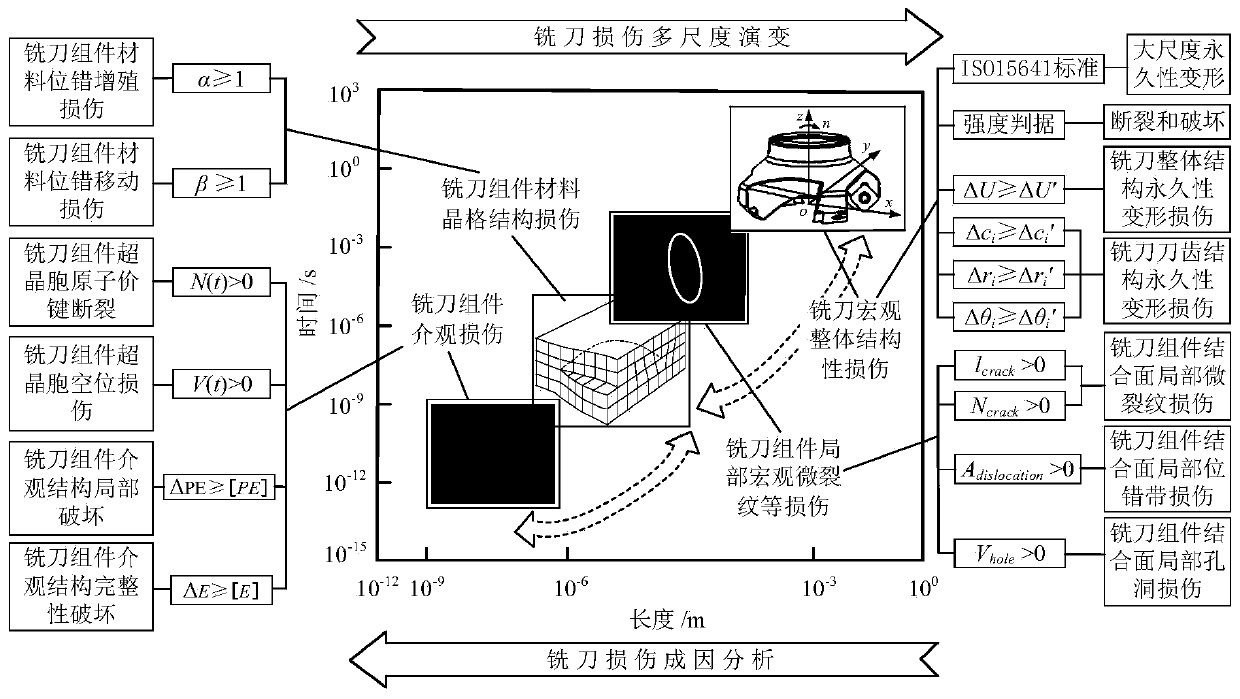

[0102] A multi-scale identification method for efficient milling cutter damage, comprising the following steps:

[0103] Step a, scale division of milling cutter damage identification criteria;

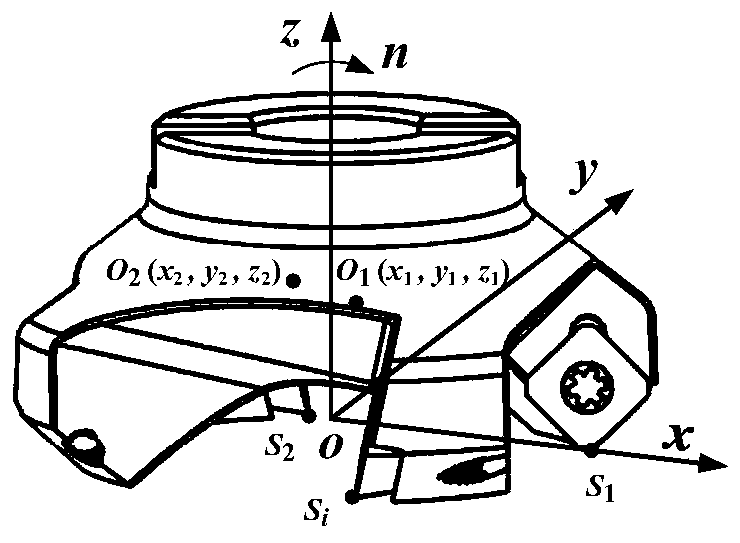

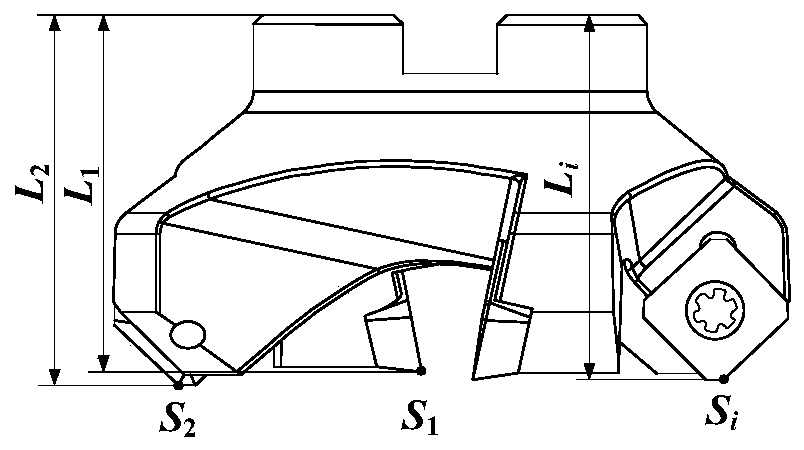

[0104] Step b, establishing the milling cutter structure and its working load characteristic model;

[0105] Step c, measuring and identifying the permanent deformation of the milling cutter;

[0106] Step d, milling cutter stress field analysis and local damage discrimination;

[0107] Step e, identifying damage to the material tissue structure of the milling cutter assembly;

[0108] Step f, identification of mesoscopic damage formation of the milling cutter assembly;

[0109] Step g, multi-scale identification and experimental verification of milling cutter damage.

[0110] Further: the scale division of the milling cutter damage identification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com