Hollowed-out pipe orifice shrinking device

A shrinking device and hollow-out technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as single function of the nozzle shrinking device, increase equipment maintenance costs, and affect the normal use of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

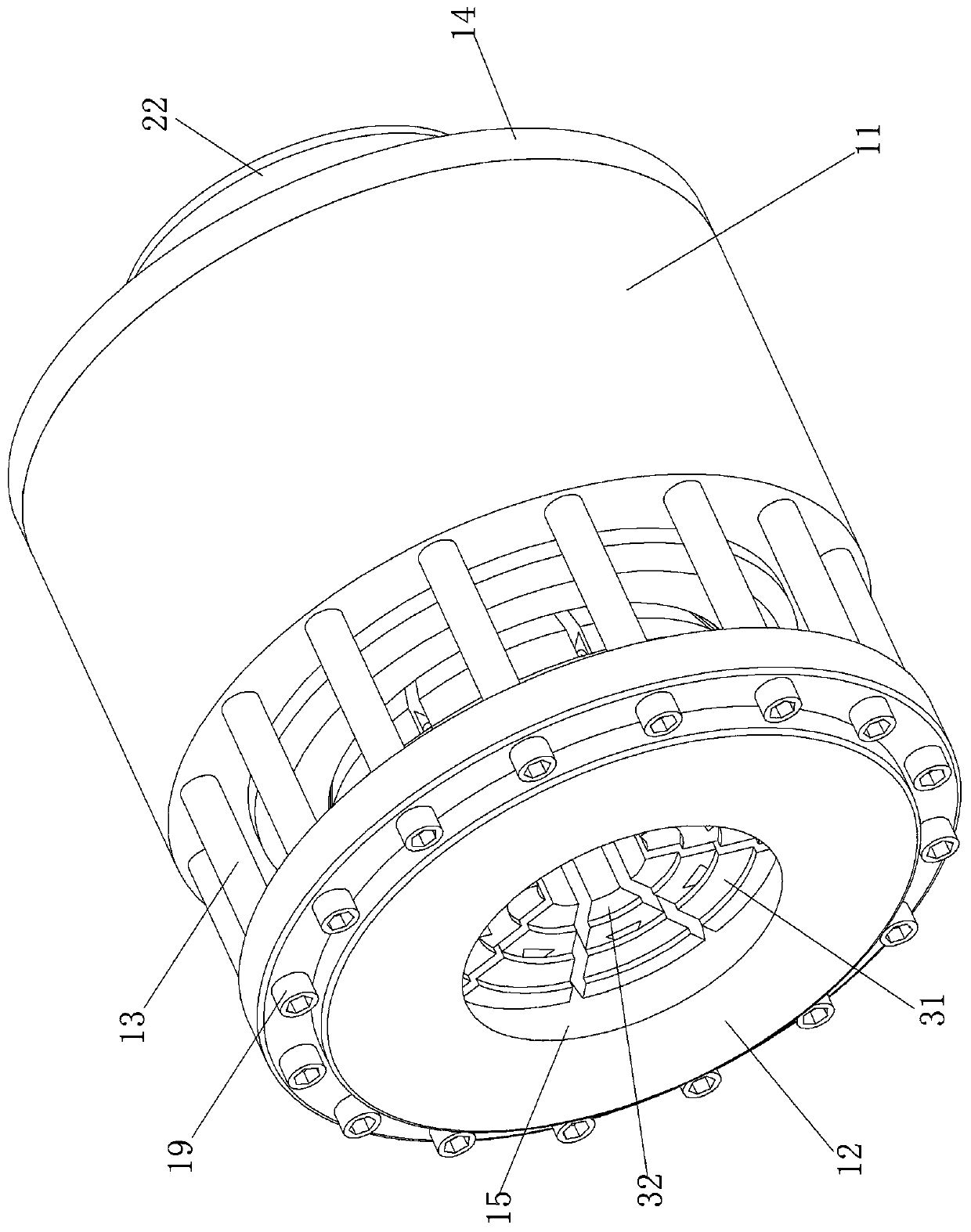

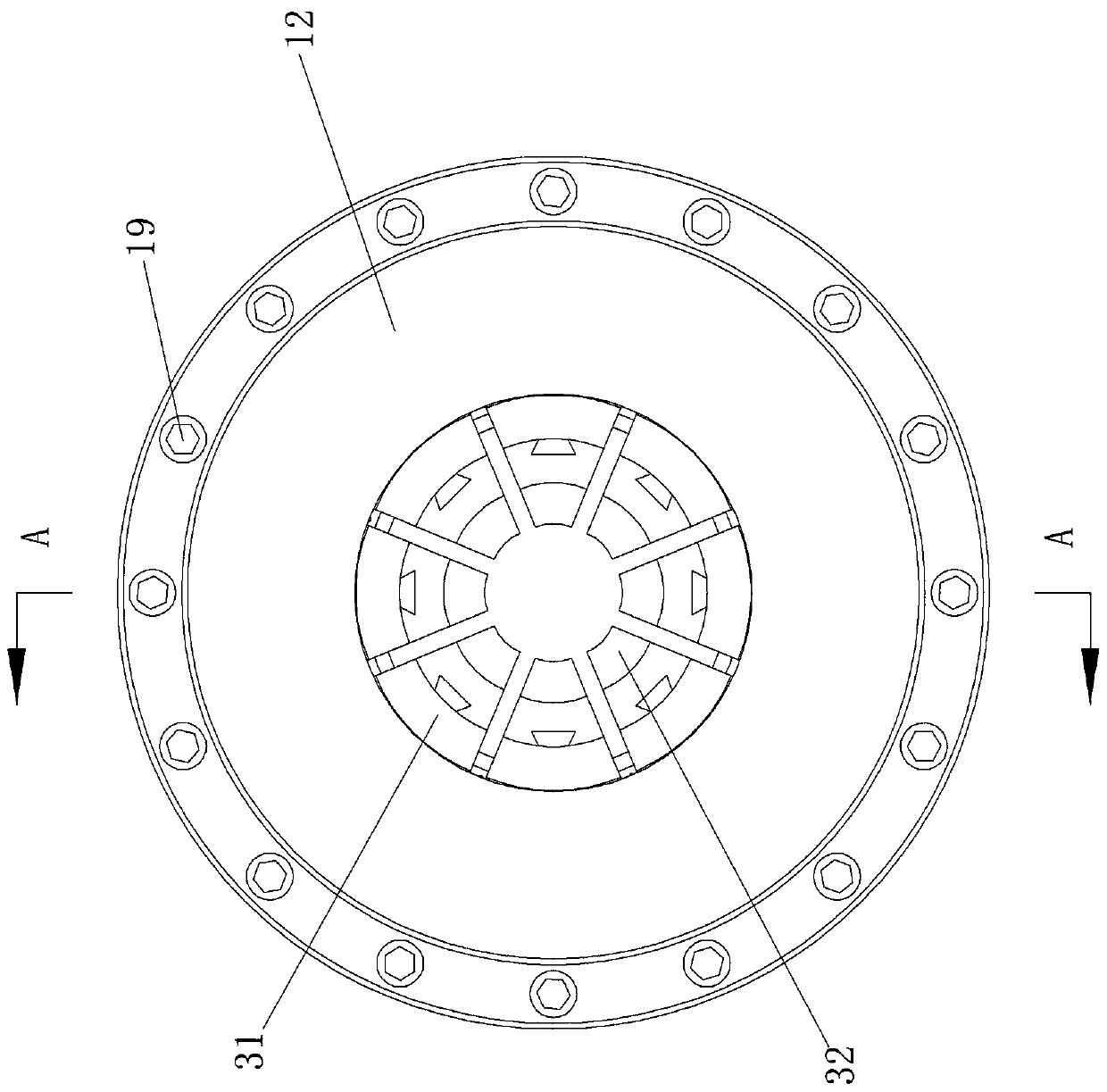

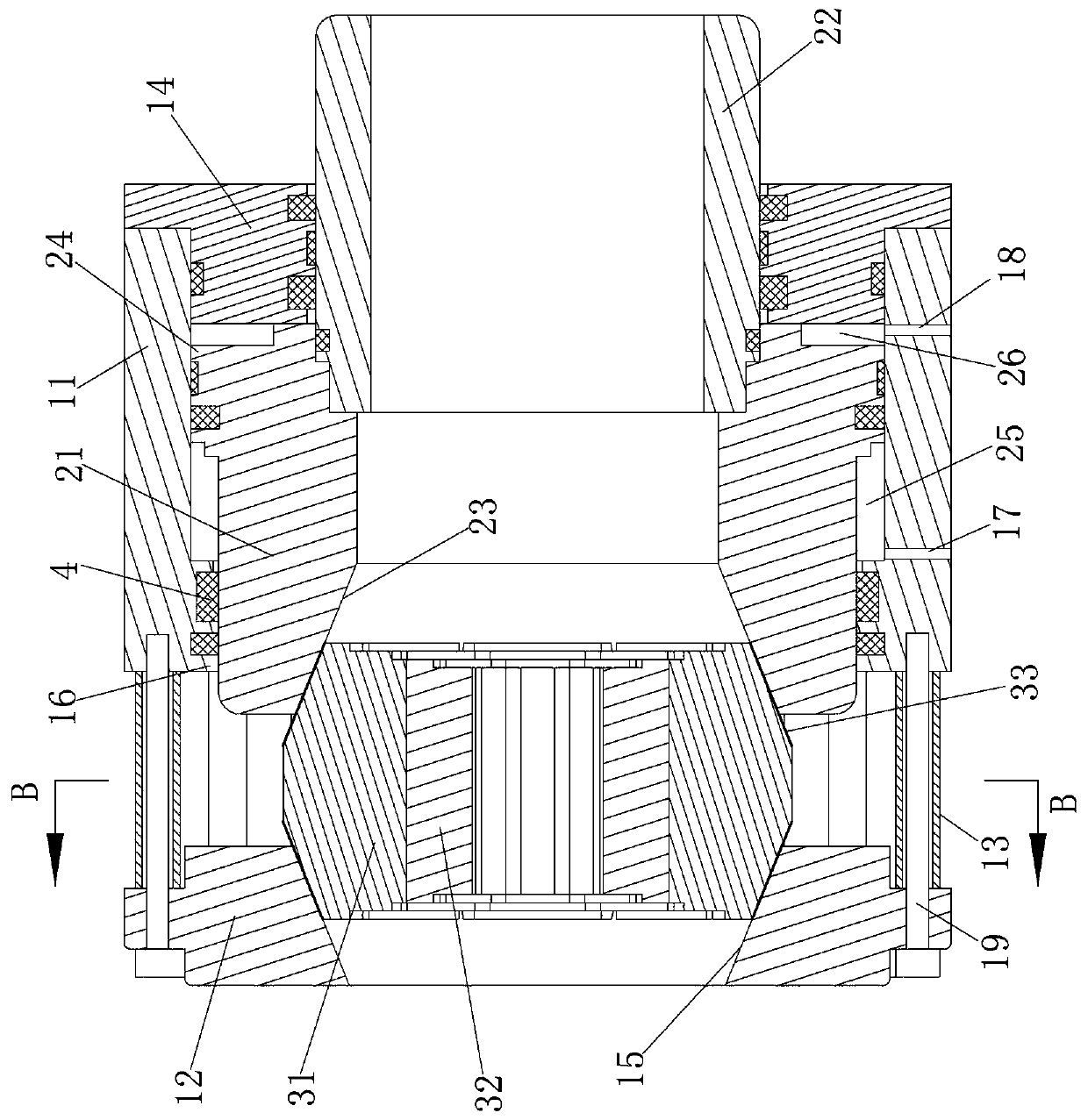

[0023] Embodiment one, see Figure 1-6 , a hollowed-out nozzle shrinking device, the device includes a fixed seat, a drive body installed inside the fixed seat and a shrinking mold;

[0024] The fixed seat includes a cylindrical main body, a guide flange and a sealing end plate respectively fixed at both ends of the main body, and the guide flange is fixed on the outer surface of the main body by bolts uniformly distributed along its edge and along the circumference. On the end face, the bolts horizontally penetrate the guide flange and are screwed on the outer end face of the main body. A sleeve is set on each bolt and the two ends of the sleeve are respectively supported on the end face of the guide flange and the main body. The guide flange is fixed on the main body through the bolt sleeve, and a hollow area is formed between them. When the tube is shrunk, the slag and other sheds can fall out through the gap between the mold seat monomers and the hollow area. To prevent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com