Application of Semiconductor Composite Materials Modified by Fullerene Derivatives in Photocatalytic Degradation of Formaldehyde

A technology of fullerene derivatives and composite materials, applied in photocatalytic degradation of formaldehyde, in the field of semiconductor composite materials, can solve the problem of high recombination rate of photogenerated carriers, few semiconductor composite materials, rare and expensive precious metals, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

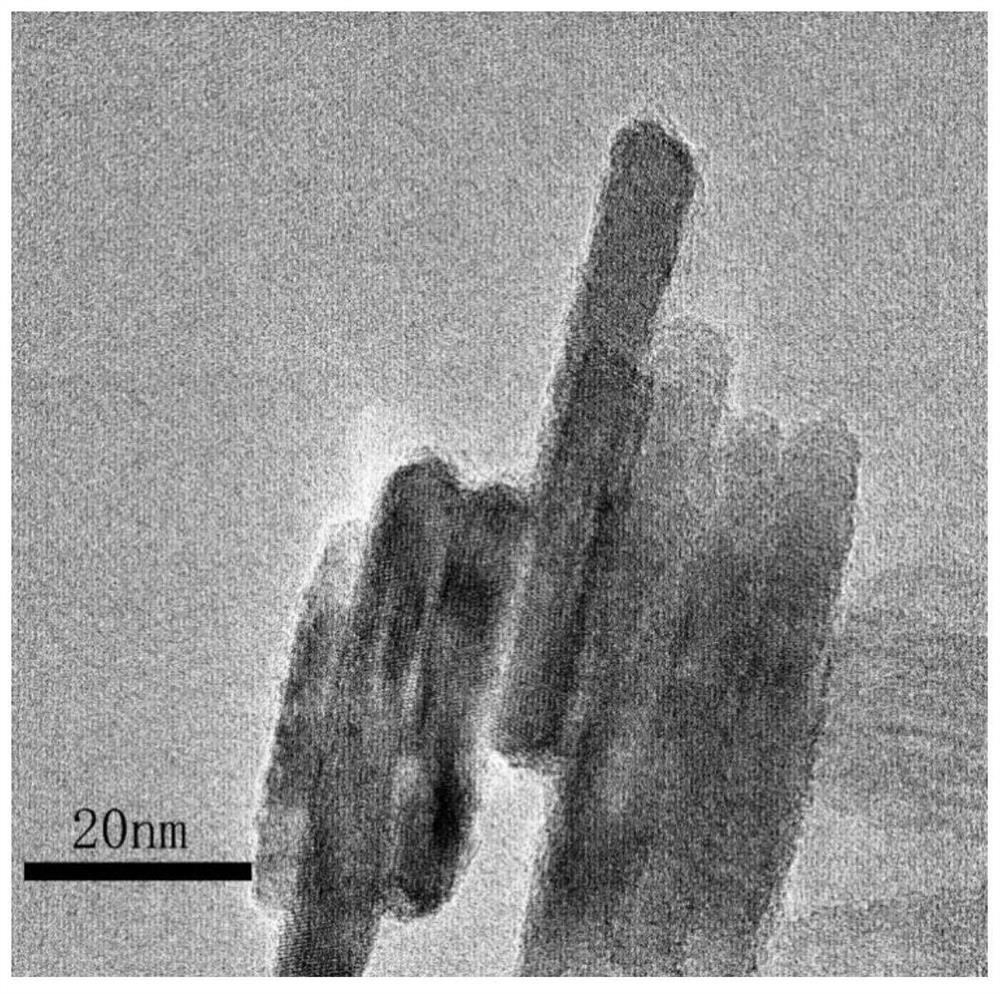

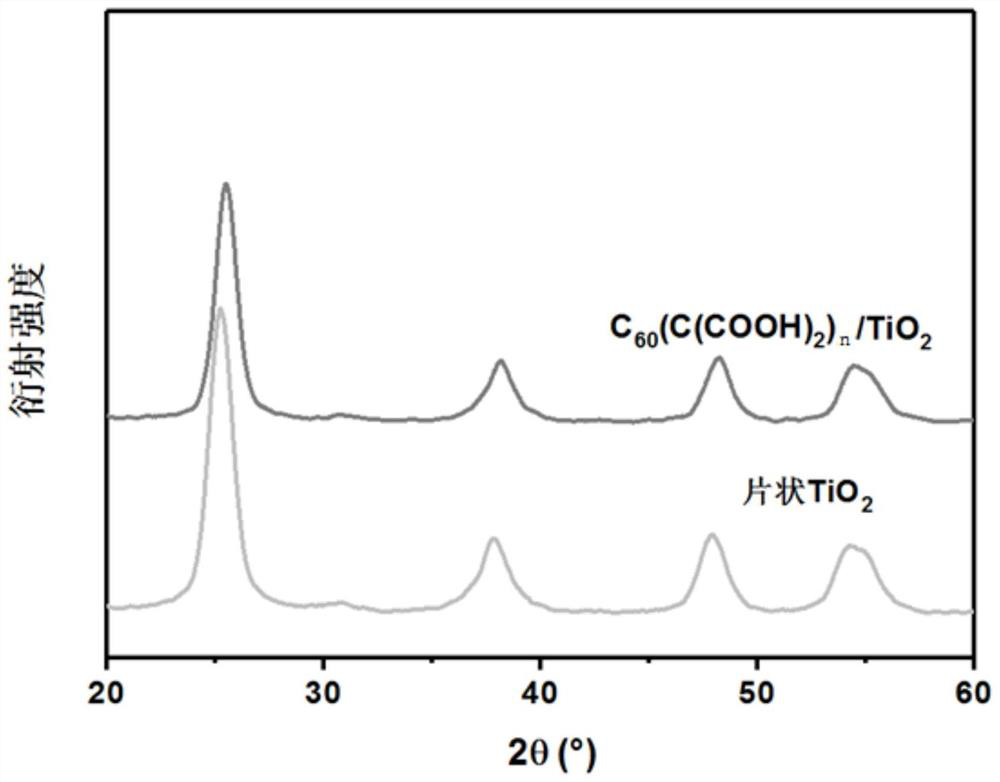

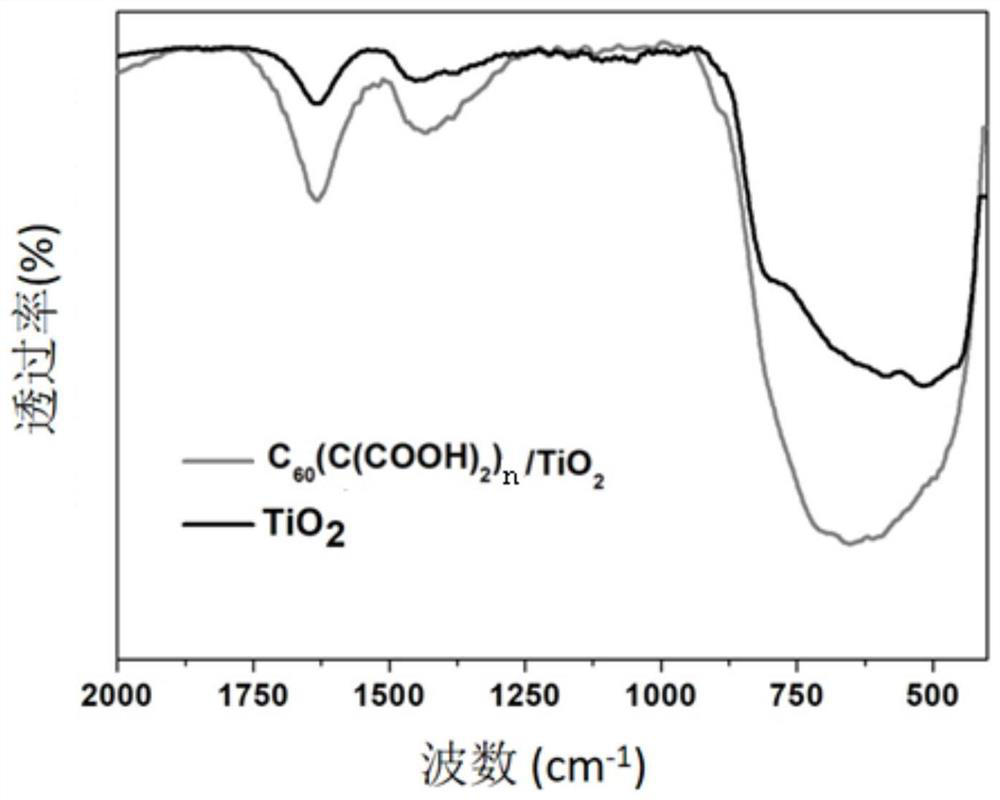

[0062]Example 1-1 C60Carboxyl derivative modified TiO2Composite material C60(C(COOH)2)n / TiO2Preparation

[0063]Flake TiO2Preparation: Mix 0.07 mol of tetrabutyl titanate and 5ml (40wt%) of hydrofluoric acid to control pH to obtain a mixed solution. The mixed solution is placed in a 100ml reactor and kept at 200°C for 20 hours. After the reaction, the temperature is lowered to obtain a flake The solution of titanium dioxide was filtered by centrifugation, washed with deionized water 3 times, and then washed 3 times with absolute ethanol, and dried overnight in an oven at 80° C. to obtain 0.068 mol of flake titanium dioxide solid powder.

[0064]Granular TiO2Preparation: Mix 17.5ml of ethanol and 35ml of water with ultrasonic for 15min to obtain a mixed solution, then add 3.4ml of tetrabutyl phthalate to another 17.5ml of ethanol, and then add the tetrabutyl titanate ethanol solution dropwise under stirring Into the above mixed solution, continue to stir for 2h, transfer the resulting susp...

Embodiment 1-2

[0074]Example 1-2 C60Amino derivative modified TiO2Composite material C60(EDA)n / TiO2Preparation

[0075]Flake TiO2Preparation method, particle TiO2The preparation method is the same as in Example 1-1.

[0076]C60Aminated derivative C60(EDA)nPreparation: Weigh 50mg of solid fullerene C with an analytical balance60Dissolve in 25ml of o-xylene solution, disperse ultrasonically for 30min, measure 50L of ethylenediamine into a 100ml conical flask with stopper, add a magnetic stirrer, stir for 24h with a magnetic stirrer (temperature: room temperature, speed: 1000r / min), using a solvent filter (volume: 1L, filter membrane pore size: 200nm) to suction filter the reactants to obtain a brown-red solution. The components of the solution are mainly ethylenediamine and C that have not participated in the reaction60(EDA)nAnd the solvent o-xylene. The obtained solution was put into a 250 ml round bottom flask, and then the filtrate was dried by rotary evaporation using a rotary evaporator (temperature...

Embodiment 1-3

[0082]Example 1-3 C60Hydroxylated derivative C60(OH)n / TiO2Modified TiO2Preparation of composite materials

[0083]Flake TiO2Preparation method, particle TiO2The preparation method is the same as in Example 1-1.

[0084]C60Hydroxylated derivative C60(OH)nPreparation: 100 mg C60Add 20ml o-xylene to dissolve ultrasonically, add potassium hydroxide solution (4g potassium hydroxide+4ml water) dropwise under stirring at 40°, add 200μl tetrabutylammonium hydroxide aqueous solution, react for 24 hours, reduce pressure at 40° Rotate and evaporate o-xylene, add 4 ml of water and continue to react at 40 degrees for 24 hours, add 10 times anhydrous ethanol and let stand for 10 minutes, centrifuge, dissolve a small amount of water and then add anhydrous ethanol, centrifuge, the same method twice, precipitation After dissolving 50 ml of water ultrasonically, pass it through a 0.22 micron filter membrane, dialyze for two to three days, until the conductivity is close to that of pure water, and evaporate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com