Cooling device, cell module, and method for manufacturing cooling plate of cooling device

A technology for cooling devices and unit batteries, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of lack of external casings, and achieve the effect of saving assembly costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

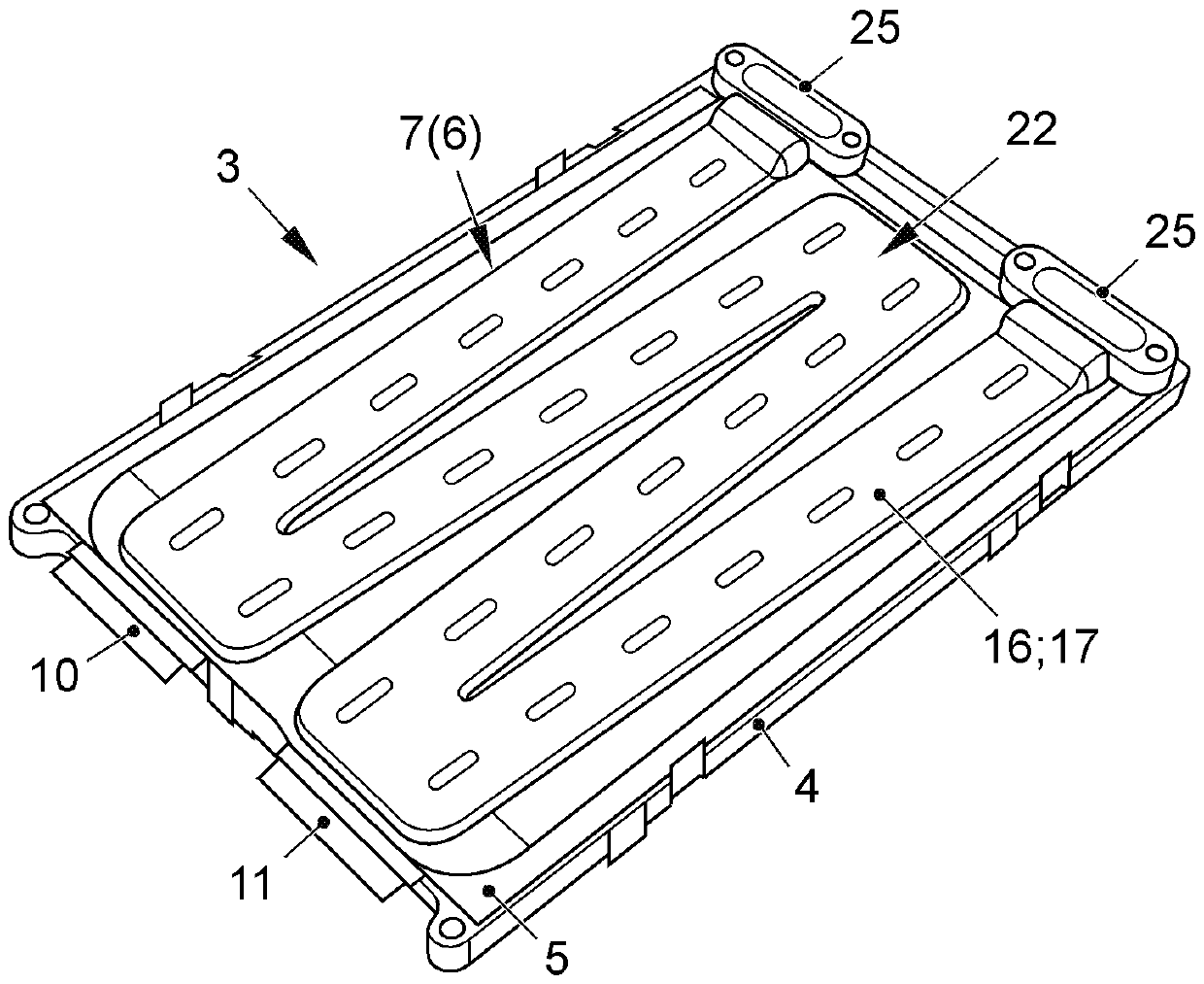

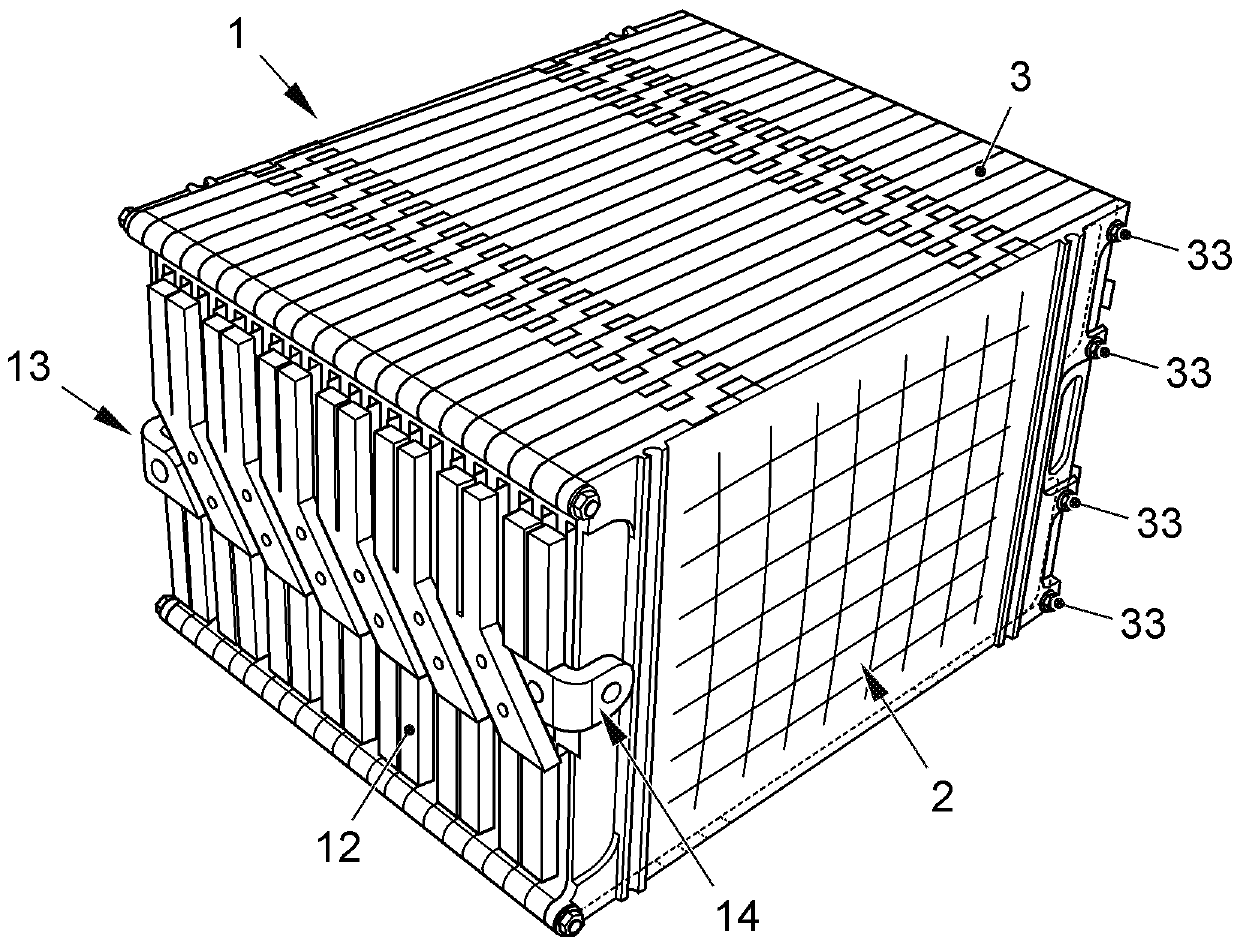

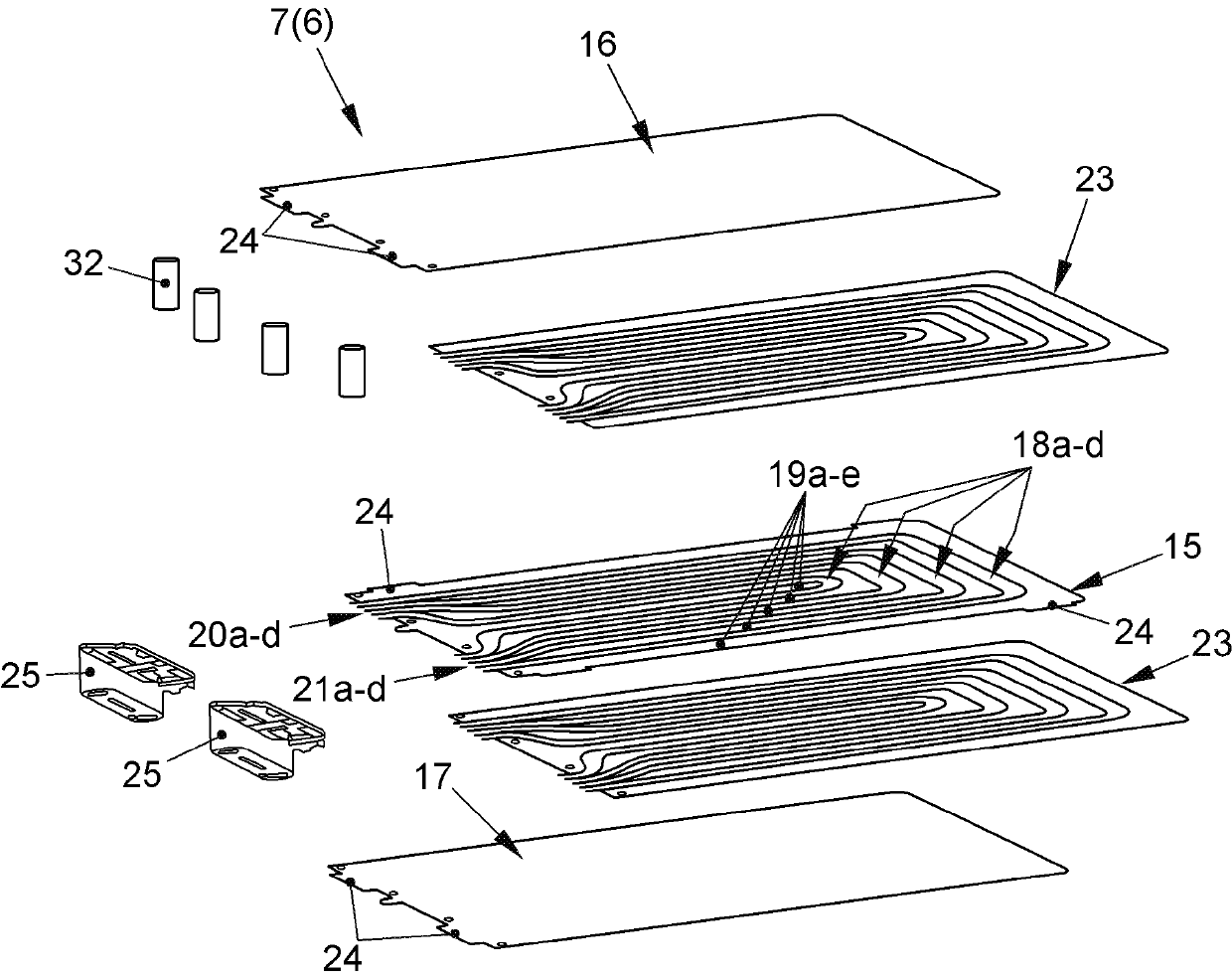

[0063] figure 1 Firstly, a cell module 1 is shown, which has a plurality of so-called module boxes 3 combined in a module housing 2 . according to figure 2 and 3 Each module box 3 has a frame element 4 in or at which plate-shaped battery cells 5 , in particular pouch-shaped cells, and a cooling device 6 are fastened. According to this embodiment, the battery cells 5 and the cooling plate 7 of the cooling device 6 are in large-area contact with an interposed film 8 acting as an insulator, in particular a polyimide film, which can be difficult to Ignite and are high temperature resistant and have a high electrical breakdown field strength. On the other side of the battery cell 5 there is provided a plate-shaped foam element 9 which contacts the adjacent module box in the form of a compound with the other module box 3 within the cell module 1 3 or its foam element 9 or cooling plate 7 (not shown in a drawn manner). The mentioned foam element 9 serves to absorb any pending e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com