Gas-liquid combination directional cracking device and method

A cracking, gas-liquid technology, applied in the field of gas-liquid combined directional cracking device, can solve problems such as poor cracking effect of liquid carbon dioxide phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

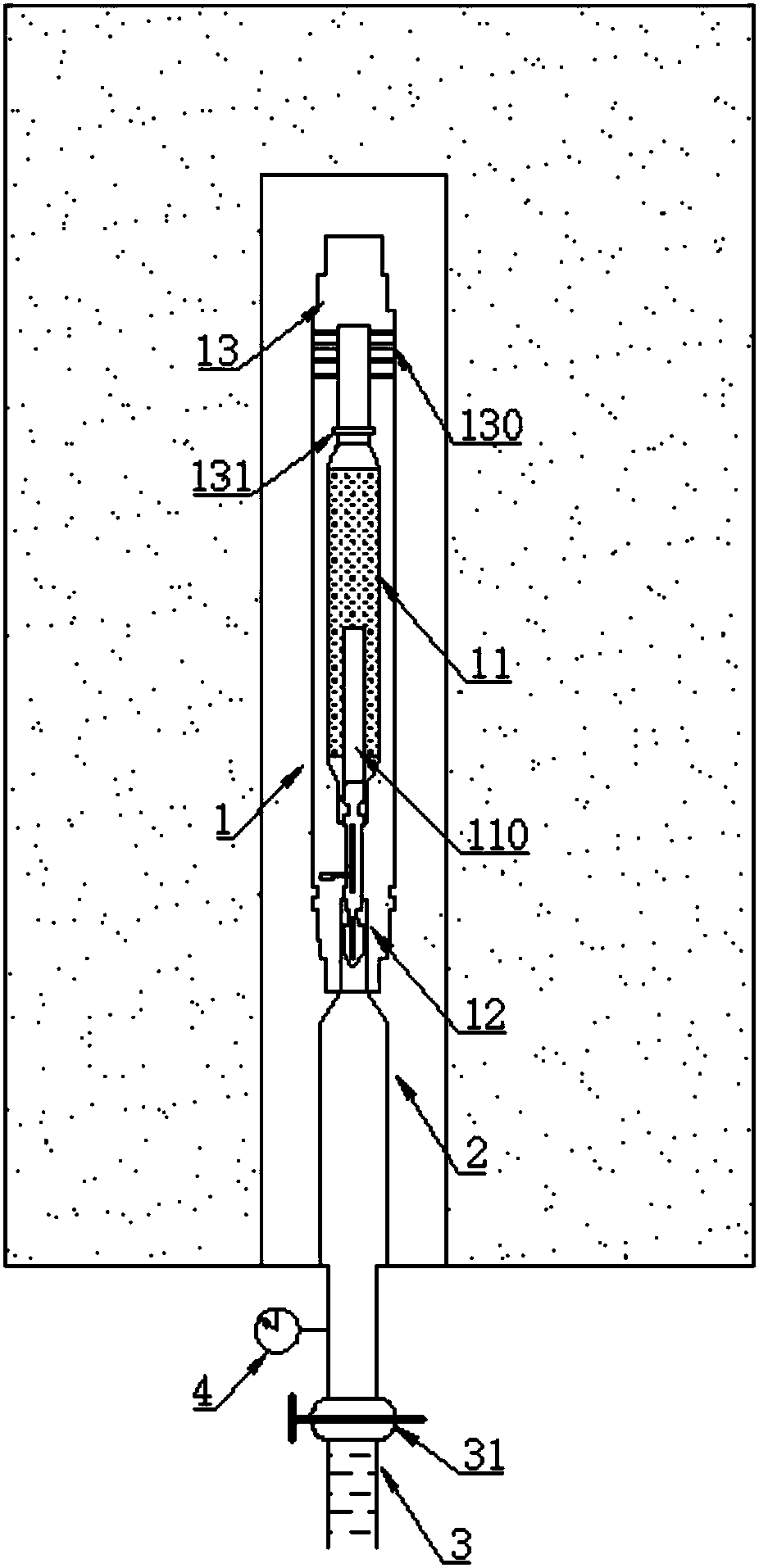

[0048] figure 1 Schematic diagram of the structure of the gas-liquid combined directional fracturing device provided in Example 1, as shown in figure 1 As shown, this embodiment provides a gas-liquid combined directional fracturing device, including: CO 2 Phase change generator 1 and hole sealer 2. The gas-liquid combination directional fracturing device is arranged in the pre-constructed borehole, in which:

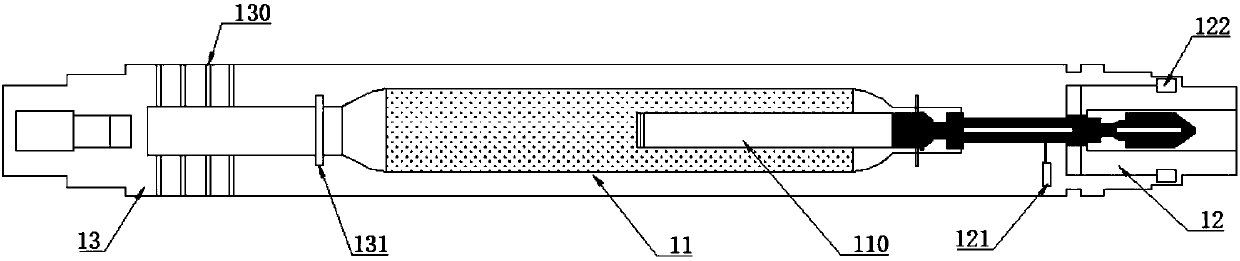

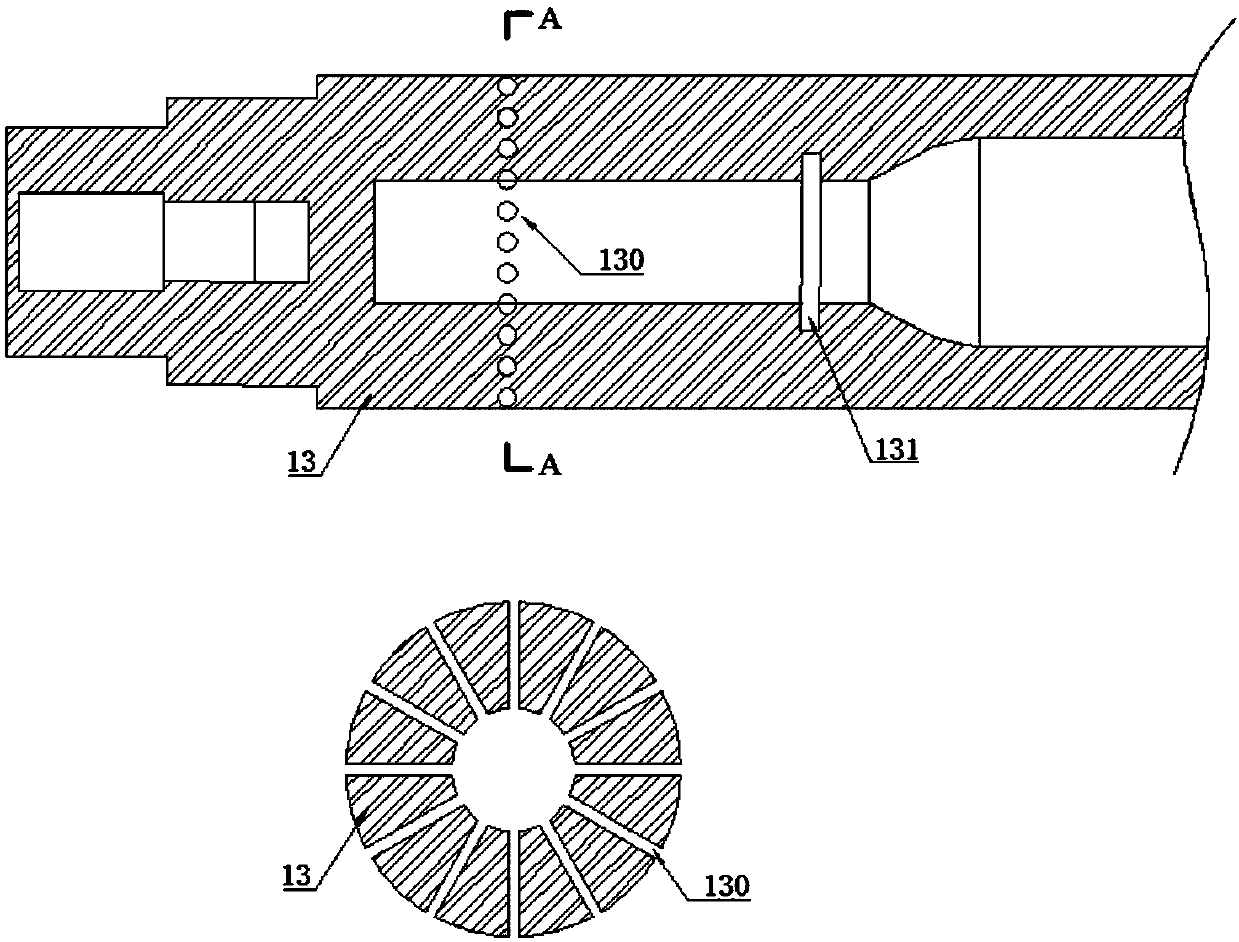

[0049] Such as figure 2 as shown, figure 2 CO provided for Example 1 2 Schematic diagram of the structure of the phase change generator, CO 2 The phase change generator 1 is a cylindrical structure with liquid CO stored inside 2 , CO 2 The first end of the phase change generator 1 is provided with a plurality of nozzles 130 , and the second end thereof is connected to the hole sealing device 2 . CO 2 Phase change generator 1 is used to convert liquid CO 2 to gaseous CO 2, and is filled into the borehole by the spout 130, and the borehole is pre-cracked. The...

Embodiment 2

[0063] Figure 5 The schematic diagram of the gas-liquid combined directional fracturing device provided for Example 2, as Figure 5 As shown, on the basis of the above-mentioned first embodiment, this second embodiment provides another gas-liquid combined directional fracturing device.

[0064] In coal mines, for hard roof or top coal, in order to improve the effect of fluid pressure fracturing, multiple linearly arranged drill holes can be densely constructed in the same plane. A set of gas-liquid combination directional fracturing device is arranged in each borehole, and the heating module 110 of each gas-liquid combination directional fracturing device is led out of the hole through the lead wire 111 to be connected in series; The high-pressure water pipe 3 connected to the hole sealer 2 in the directional fracturing device is connected in parallel through the multi-way 5, and a general water injection valve 31 is set on the multi-way to open or close the water injection ...

Embodiment 3

[0070] Image 6 A schematic flow chart of the gas-liquid combined directional fracturing method provided in Example 3; Figure 7 In the gas-liquid combined directional fracturing method provided in Example 3, the liquid CO 2 Schematic flow chart of phase change fracturing and hydraulic fracturing. Such as Image 6 with Figure 7 As shown, the present invention provides a gas-liquid combination directional fracturing method. The gas-liquid combination directional fracturing method provided in this embodiment uses the gas-liquid combination directional fracturing device provided in the above-mentioned embodiment 1 or embodiment 2 to realize coal Rock internal fluid pressure fracture. Specifically, such as Image 6 As shown, the gas-liquid combined directional fracturing method provided in this embodiment includes:

[0071] S101: Drilling at least one borehole in the coal body;

[0072] Specifically, the depth and extension direction of the construction borehole can be com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com