A kind of preparation method of high-efficiency inhibitor for coal mine

An inhibitor and high-efficiency technology, which is applied in the field of preparation of high-efficiency inhibitors for coal mines, can solve the problems of low inhibition efficiency and low inhibition efficiency of high-efficiency inhibitors, and achieve improved inhibition efficiency and inhibition effect Improve and ensure the effect of coal mine safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

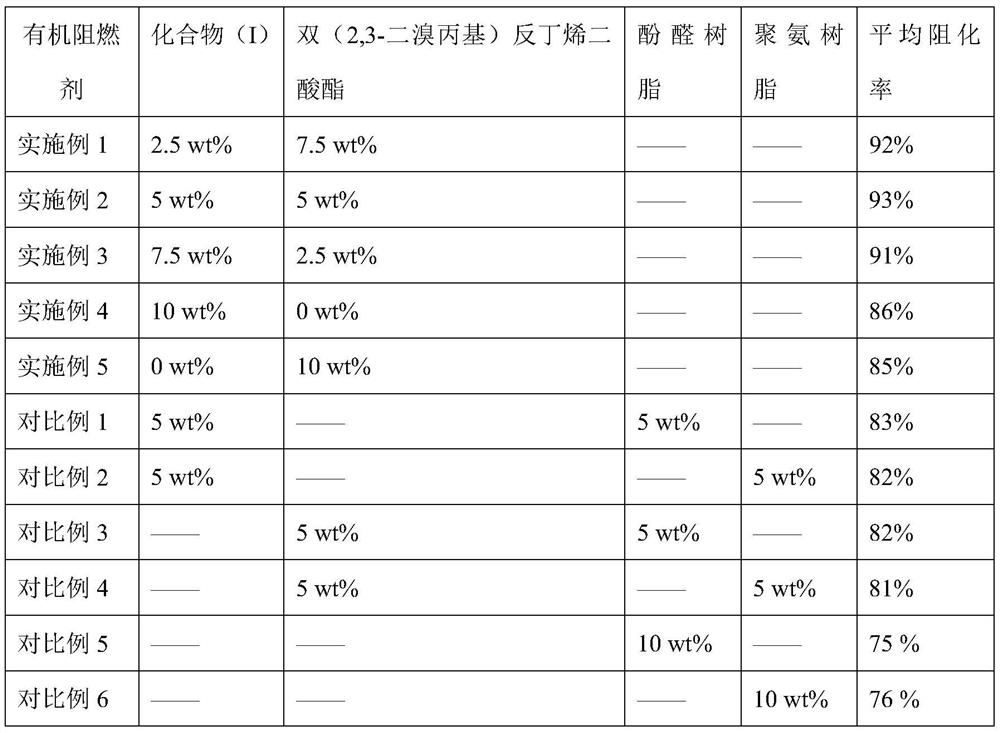

Embodiment 1

[0031] A high-efficiency inhibitor for coal mines consists of the following components:

[0032] Compound (I) 2.5wt%;

[0033] Bis(2,3-dibromopropyl)fumarate 7.5wt%;

[0034] Inorganic flame retardant 10wt%;

[0035] Surfactant 10wt%;

[0036] Sodium percarbonate 10wt%;

[0037] the rest is water;

[0038] Wherein, the inorganic flame retardant is magnesium chloride, and the surfactant is sorbitan fatty acid ester;

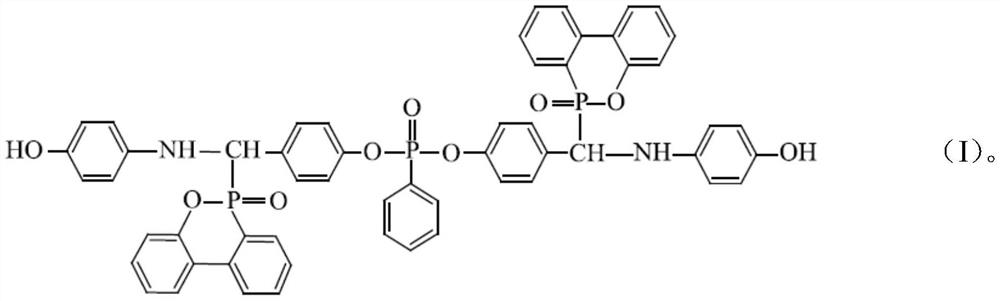

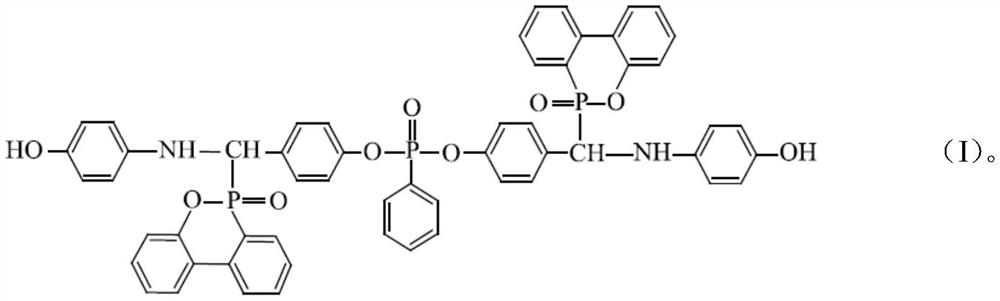

[0039] Wherein, the structural formula of compound (I) is as follows:

[0040]

[0041] The preparation process of this inhibitor is as follows:

[0042] A. Mix inorganic flame retardant, surfactant, sodium percarbonate and water in a certain proportion;

[0043] B. Filter the solution with a 1000-mesh filter, cool and let it stand;

[0044] C. Add the solution into the reactor and heat it. The heating temperature is 60° C. and the heating time is 45 minutes;

[0045] D. Stir and add a certain amount of organic flame retardant at the same time, the sti...

Embodiment 2

[0052] The mass fraction of compound (I) and bis(2,3-dibromopropyl) fumarate in Example 1 is replaced by 5wt% and 5wt% respectively, and all the other process parameters, process steps, assay methods and implementation Example 1 is exactly the same. The averaging rate results of Example 2 are listed in Table 2.

Embodiment 3

[0054] The massfraction of compound (I) and two (2,3-dibromopropyl) fumarate in embodiment 1 is changed to 7.5wt% and 2.5wt% respectively, all the other process parameters, process steps, assay method Exactly the same as Example 1. The average resistivity results of Example 3 are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com