Inorganic nanomaterial printing ink and its preparation method and application

A technology of inorganic nanomaterials and printing inks, applied in inks, applications, household appliances, etc., can solve the problems of comprehensive stability of printing ink volatilization rate, dispersibility, viscosity, surface tension, etc., to maintain dispersion stability, Improved film formation and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Correspondingly, an embodiment of the present invention provides a method for preparing an inorganic nanomaterial printing ink, comprising the following steps:

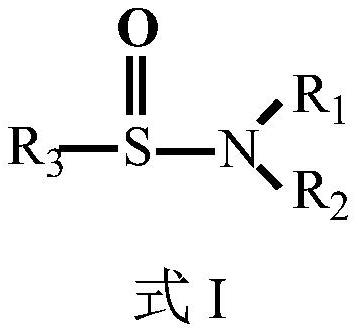

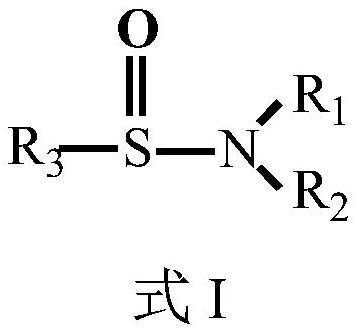

[0061] S01. Provide inorganic nanomaterials and organic solvents, the organic solvents contain at least one sulfenamide organic solvent;

[0062] S02. Dissolving the inorganic nanomaterials in an organic solvent to form the inorganic nanomaterial printing ink.

[0063] The preparation method of the inorganic nanomaterial printing ink provided in the embodiment of the present invention only needs to dissolve the inorganic nanomaterial in an organic solvent containing a sulfenamide solvent with a specific structure, the operation is simple and easy to control, and no strict conditions are required , can realize mass production.

[0064] Specifically, in the above step S01, the type of the sulfenamide organic solvent can be referred to above. Specifically, the organic solvent contains at least one organic solvent...

Embodiment 1

[0077] An inorganic nanomaterial printing ink, comprising oleylamine-stabilized quantum dots, organic solvents and auxiliary reagents, wherein the mass ratio of the oleylamine-stabilized quantum dots to the organic solvent is 15:85; the organic solvent is represented by weight percent It is composed of dodecane and N-tert-butylbenzenesulfenamide in a ratio of 60:25, and the dodecane and N-tert-butylbenzenesulfenamide silicon are both dehydrated and deoxygenated to a purity greater than 99.9%; The auxiliary reagent is polypyrrole.

[0078] A method for preparing an inorganic nanomaterial thin film, comprising the following steps:

[0079] S11. Weigh each component according to the formula of the above-mentioned inorganic nanomaterial printing ink;

[0080] S12. Provide a 500mL single-necked flask, and add oleylamine-stabilized red CdSe / ZnS quantum dots, dodecane, polypyrrole and N-tert-butylbenzenesulfinamide under stirring, and stir and mix for 30min to obtain a quantum dot i...

Embodiment 2

[0083] A printing ink of inorganic nanomaterials, comprising oleylamine-stabilized quantum dots and an organic solvent, wherein the mass ratio of the oleylamine-stabilized quantum dots to the organic solvent is 10:90; the organic solvent is 35% by weight: 30:25 composition of 1,2,4-trimethoxybenzene, decahydronaphthalene and N-tert-butylbenzene sulfenamide, and 1,2,4-trimethoxybenzene, decahydronaphthalene and N-tert-butyl All the phenylsulfinamides are purified by dehydration and deoxygenation to a purity greater than 99.9%.

[0084] A method for preparing an inorganic nanomaterial thin film, comprising the following steps:

[0085] S21. Weigh each component according to the formula of the above-mentioned inorganic nanomaterial printing ink;

[0086] S22. Provide a 500mL high-density polyethylene bottle, and add oleylamine-stabilized green CdZnSe / CdZnS, 1,2,4-trimethoxybenzene, decahydronaphthalene, and N-tert-butylbenzenesulfin in sequence under stirring Amide, stirred and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com