Sludge deep drying method and system based on low-temperature heat source circulation

A low-temperature heat source, sludge dry powder technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of less than 10% harmless treatment rate, difficult sludge deep drying, limited dehydration degree, etc. Small emissions, improved drying effect, and reduced exhaust gas purification pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention and working process will be further described below in conjunction with accompanying drawing.

[0022] The orientation terms such as up, down, left, right, front and rear in this application document are established based on the positional relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

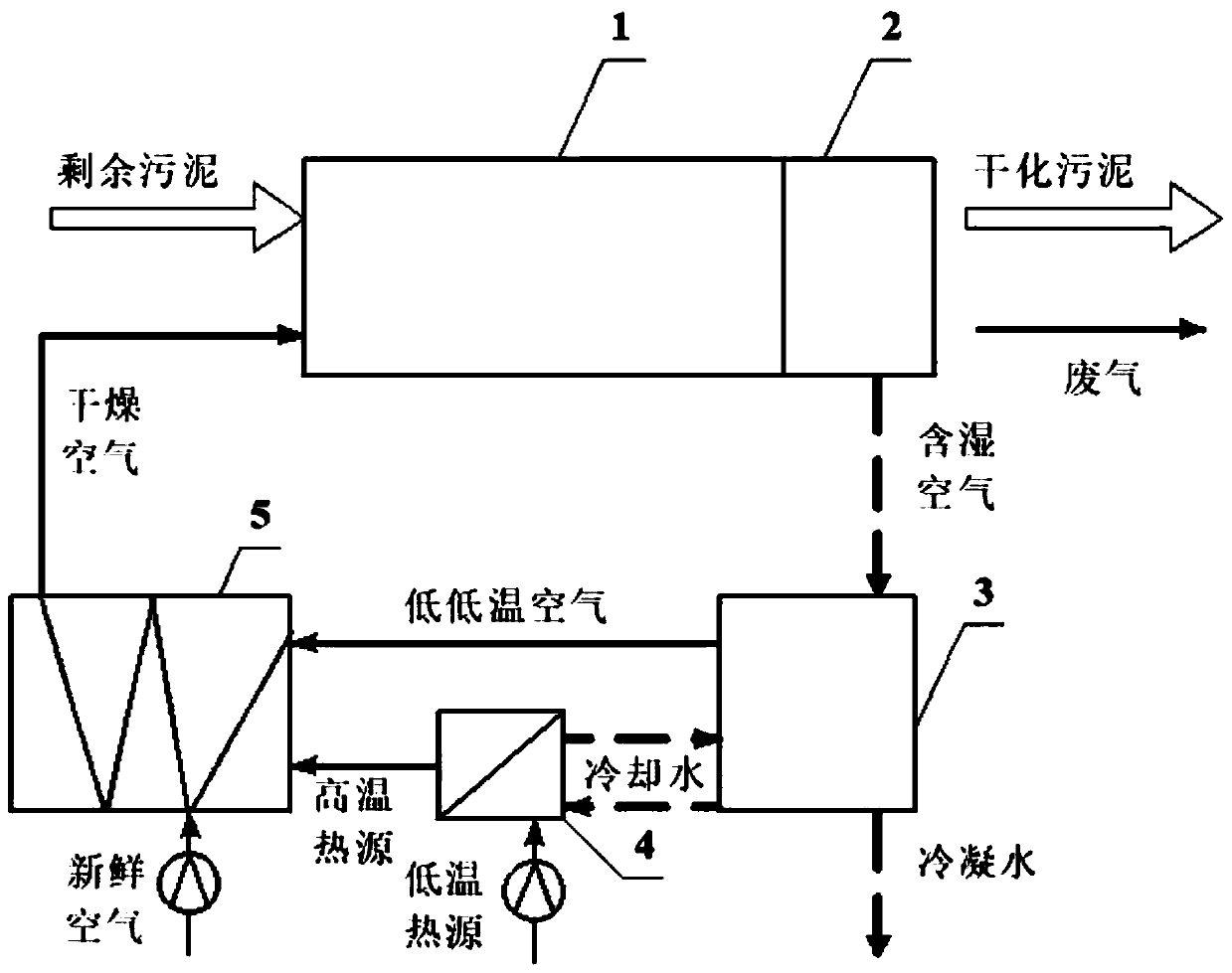

[0023] Such as figure 1 As shown, the sludge advanced drying system based on low-temperature heat source circulation includes a sludge pulverization and drying device 1 , a gas-powder separation device 2 , a condensation dehumidifier 3 , a heat pump 4 and a heat exchanger 5 . The sludge powdering and drying device 1 includes a connected pulverization chamber and a drying chamber, and the pulverization chamber is provided with a feeding device. Both the pulverization chamber and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com