River aeration membrane module, aeration membrane system and method

An aeration film and river channel technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problem of low DO content in black and odorous water, promote film formation, facilitate rapid degradation, and improve transmission quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

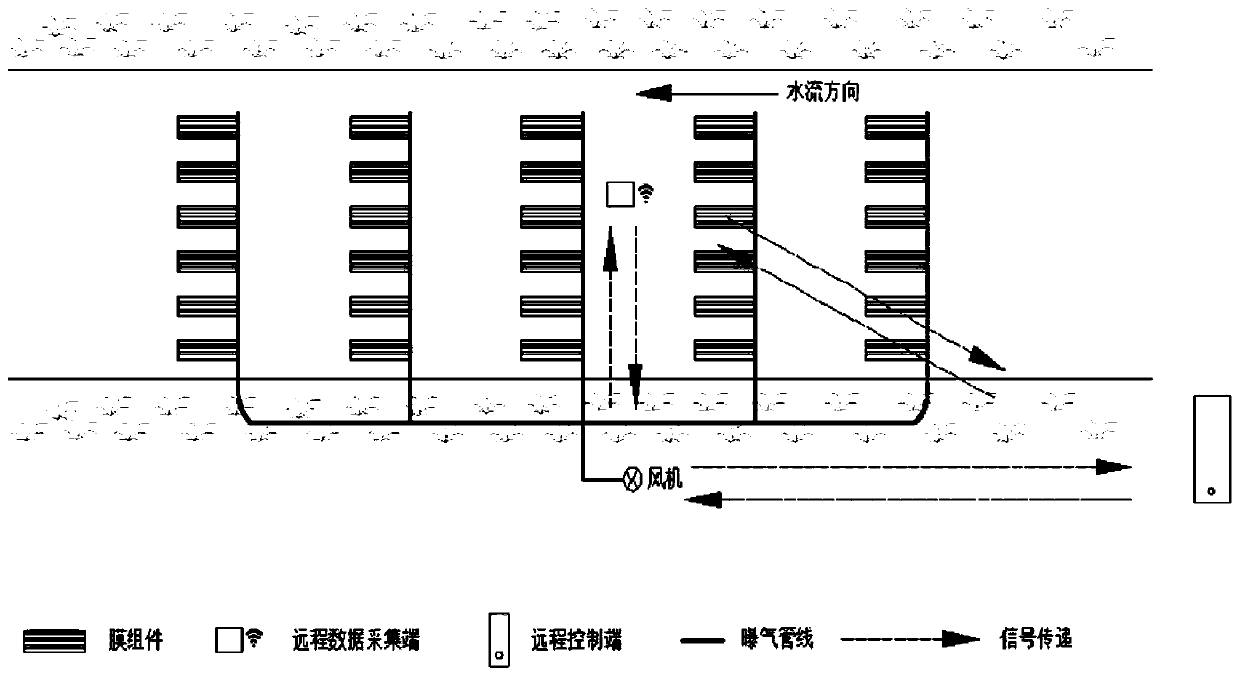

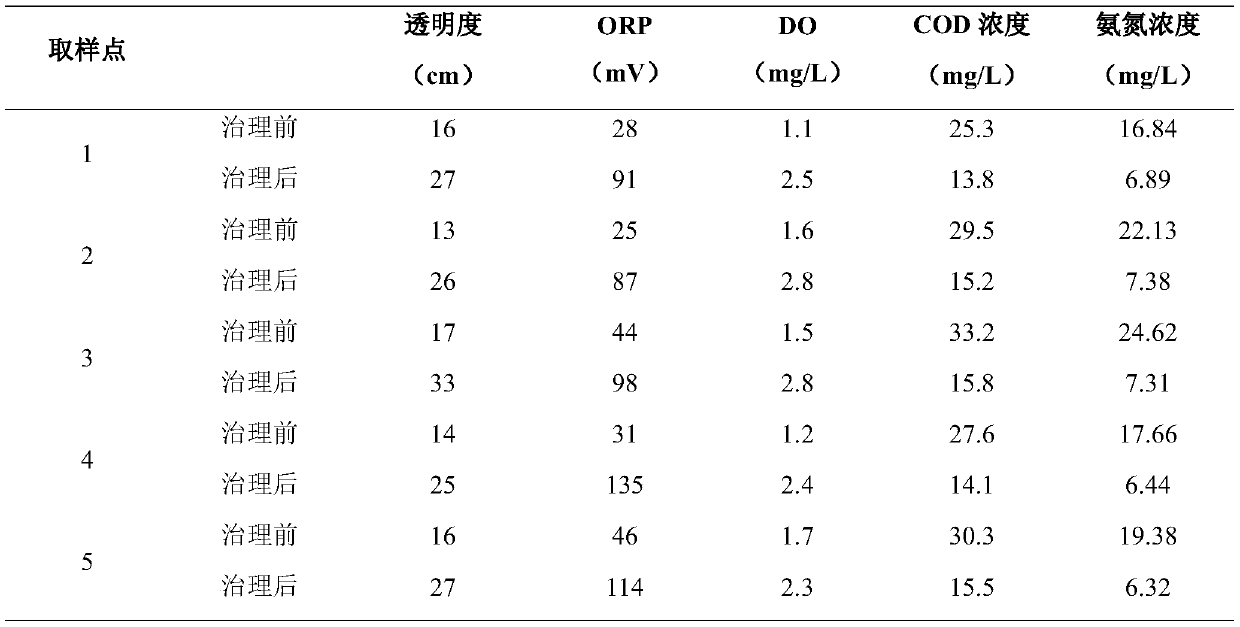

[0060] Take a project that requires oxygen enhancement and aeration as an example: select a black and odorous section of a river as the project site, the river is 2,500 meters long, and the average width is 27 meters. The COD in the water body of the river cr The concentration is 25-31mg / L; the concentration of ammonia nitrogen is 16-25mg / L; along the river, five places from 1 to 5 are selected as sampling points to detect its transparency, ORP, DO, COD concentration, and ammonia nitrogen concentration. The water temperature is 25°C) and the aeration membrane system is arranged.

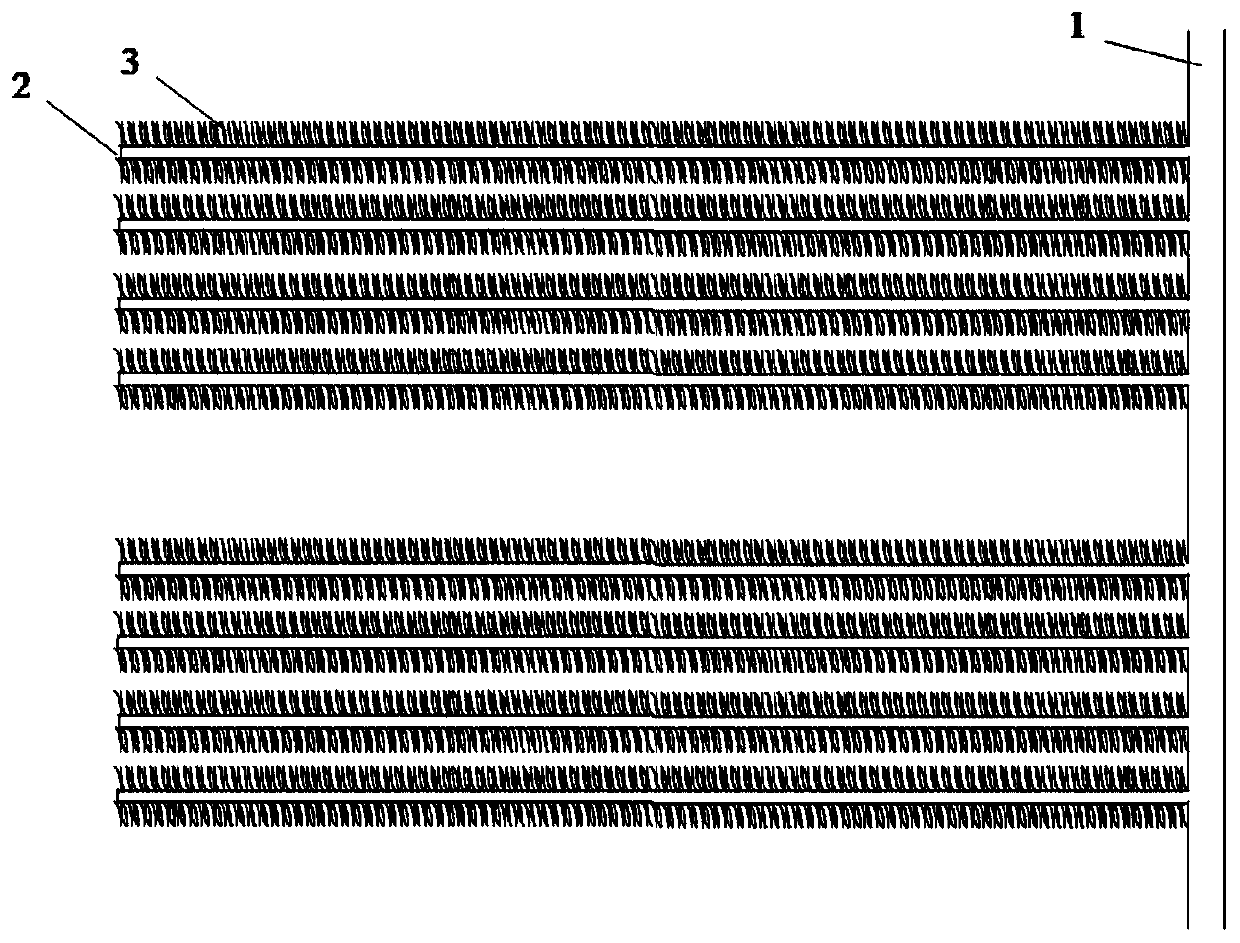

[0061] Two rows of hollow braided biofilms are distributed on each membrane module; the hollow membrane tube is made of reinforced lining PVDF material, connected to the aeration pipeline through methyl methacrylate; the inner diameter of the hollow membrane tube is 0.4mm, and the outer diameter is 1.45mm The diameter of the pores is 0.01-0.1μm; the fineness of the microporous chemical fiber membrane...

Embodiment 2

[0079] Select a black and odorous section of a river as the project site. The river is 1,200 meters long and 15 meters wide on average. The concentration of ammonia nitrogen in the water body of the river is 18.5 mg / L; a place along the river is selected as a sampling point to detect its transparency, ORP, DO, For ammonia nitrogen concentration, an aeration membrane system is arranged at a water depth of 2m (water temperature is 25°C).

[0080] Two rows of hollow braided biofilms are distributed on each membrane module; the hollow membrane tube is made of reinforced lining PVDF material, connected to the aeration pipeline through methyl methacrylate; the inner diameter of the hollow membrane tube is 0.4mm, and the outer diameter is 1.45mm The diameter of the pores is 0.01-0.1μm; the fineness of the microporous chemical fiber membrane is 0.01-0.1D, and the length is 5-10mm; the microporous chemical fiber membrane is connected with the hollow membrane tube through epoxy glue; Th...

Embodiment 3

[0086] Select a black and odorous section of a river as the project site. The length of the river is 1160 meters and the width is 13-18 meters. The concentration of ammonia nitrogen in the water body of the river is 20.5mg / L. , Ammonia nitrogen concentration, arrange the aeration membrane system at the water depth of 1m (water temperature is 25°C).

[0087] Two rows of hollow braided biofilms are distributed on each membrane module; the hollow membrane tube is made of reinforced lining PVDF material, connected to the aeration pipeline through methyl methacrylate; the inner diameter of the hollow membrane tube is 0.4mm, and the outer diameter is 1.45mm The diameter of the pores is 0.01-0.1μm; the fineness of the microporous chemical fiber membrane is 0.01-0.1D, and the length is 5-10mm; the microporous chemical fiber membrane is connected with the hollow membrane tube through epoxy glue; The surface area is 7000~7500m 2 / m 3 , the porosity is 40%-50%, and the film-forming wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com