Sorting area and stock sorting system

A technology of selecting areas and picking workers, which is applied in the field of warehousing and logistics, which can solve the problems of human and robot idle time and unfavorable picking efficiency, and achieve the effect of reducing idle waiting time and improving picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

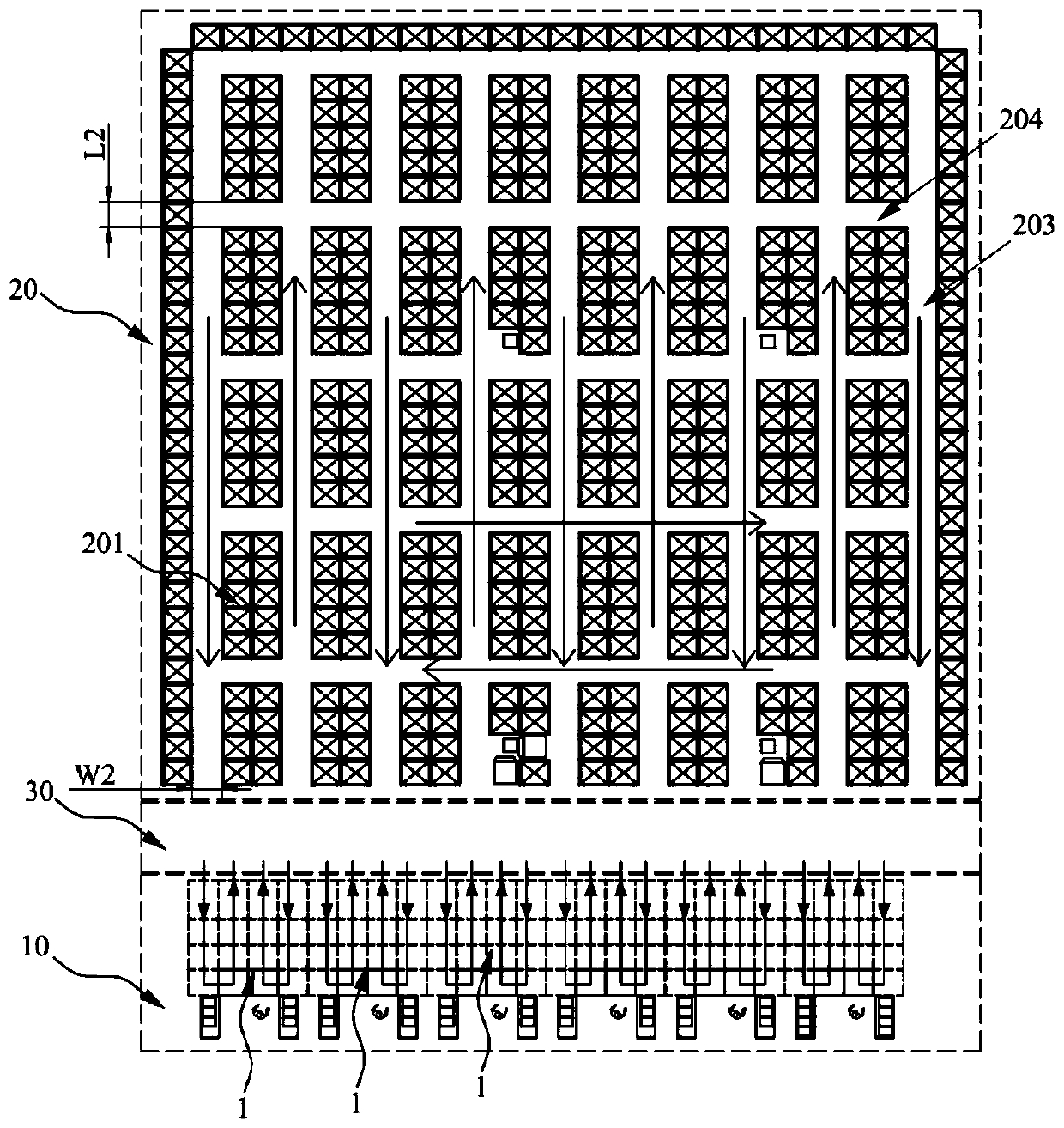

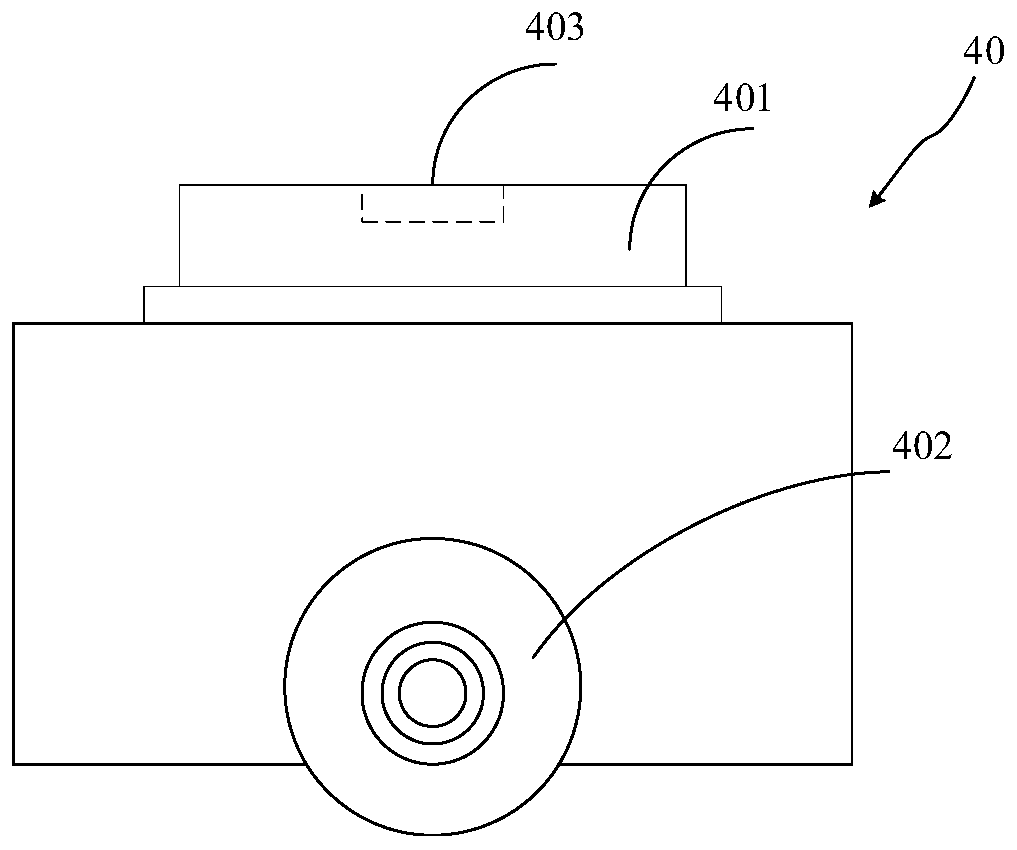

[0066] figure 1 A schematic structural view of the inventory picking system provided by the embodiment of the present invention, such as figure 1 As shown, the present embodiment provides an inventory picking system, which is mainly used in a warehouse logistics system for "goods-to-person" picking of ordered items from the inventory container 202 to the order box. This embodiment takes the application of the inventory picking system to the "goods-to-person" picking work as an example to illustrate the inventory picking system, but it can be understood that the inventory picking system provided by this embodiment is not limited to the picking of goods , and can also be applied to routine warehousing and logistics operations such as loading goods and inventory counting.

[0067] Such as figure 1 As shown, the inventory picking system provided in this embodiment includes an inventory container area 20 , a picking area 10 , a public channel area 30 and a picking robot 40 . Sto...

Embodiment 2

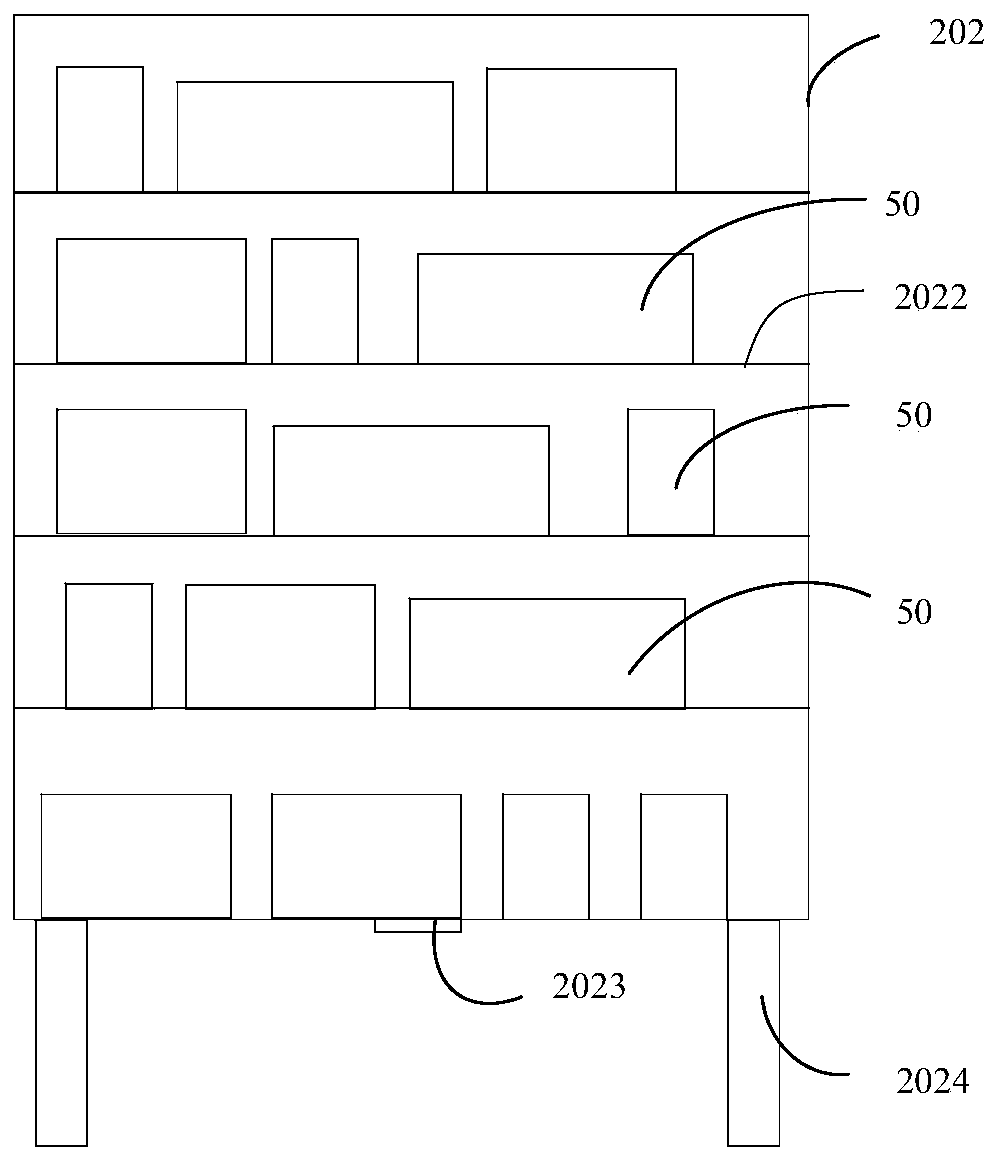

[0117] Figure 5 Structural schematic diagrams of picking stations and inventory containers provided for the embodiments of the present invention, such as Figure 5 As shown, this embodiment provides an inventory picking system, which is mainly used to realize "goods-to-person" picking of ordered goods, and can also realize conventional warehousing and logistics operations such as loading and inventory. In this embodiment, the inventory picking system includes an inventory container area 20, a public channel 30, a picking area 10, and a picking robot 40, wherein the arrangement of the inventory container area 20, the public channel 30, the picking area 10, and the picking robot 40 is basically the same as the implementation The first example is the same, only the arrangement of the sorting channel 121 in the picking station 1 is different, and this embodiment will not repeat the same structure as the first embodiment.

[0118] In this embodiment, in the same picking station 1...

Embodiment 3

[0122] Image 6 Structural schematic diagrams of picking stations and inventory containers provided for the embodiments of the present invention, such as Image 6 As shown, this embodiment provides an inventory picking system, which is mainly used to realize "goods-to-person" picking of ordered goods, and can also realize conventional warehousing and logistics operations such as loading and inventory. In this embodiment, the inventory picking system includes an inventory container area 20, a public channel 30, a picking area 10, and a picking robot 40, wherein the arrangement of the inventory container area 20, the public channel 30, the picking area 10, and the picking robot 40 is basically the same as the implementation The first example is the same, only the arrangement of the inventory container 202 in the inventory container area 20 and the arrangement of the two-dimensional grid 123 are different, and this embodiment will not repeat the same structure as the first embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com