Transformer automatic assembly method based on machine vision

A machine vision and automatic assembly technology, applied in the direction of assembly machines, manipulators, program control manipulators, etc., can solve problems such as large labor consumption, low work efficiency, and inability to guarantee product assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

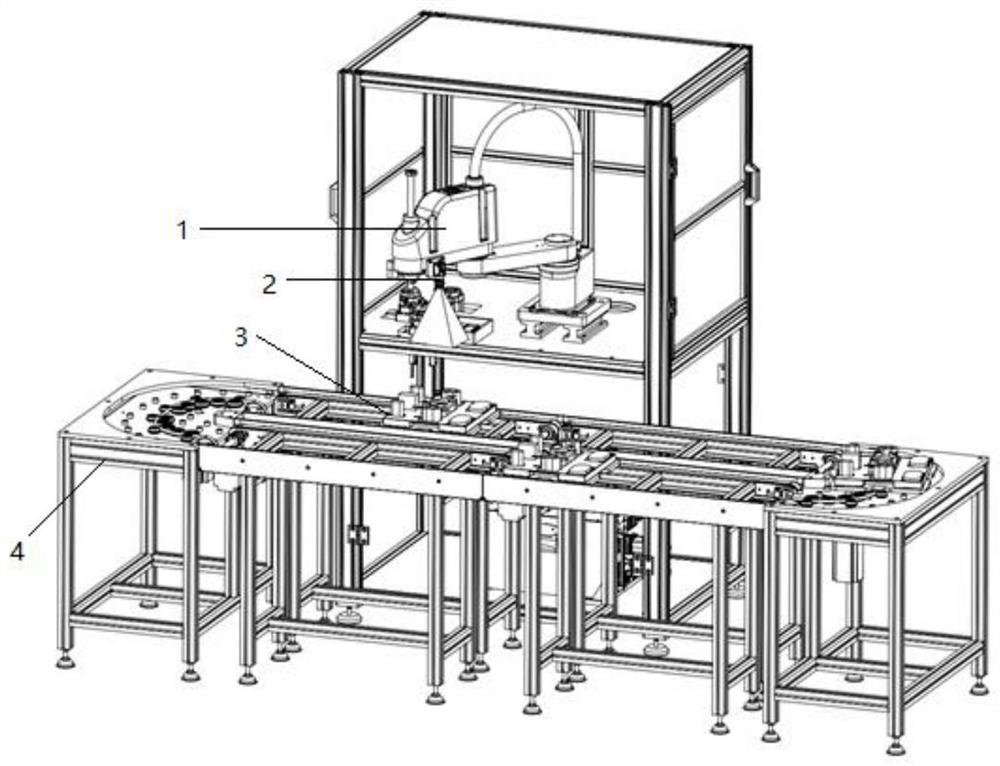

[0019] combine figure 1 , The equipment for automatic transformer assembly of the present invention includes a bracket, a manipulator 1, a camera 2, a material tray 3, and a conveyor 4. The manipulator 1 is set on the support and can rotate in three degrees of freedom, and the camera 2 is set on the manipulator 1 . The material tray 3 is arranged on the conveyor 4 , and the material tray 3 moves together with the conveyor belt of the conveyor 4 . The conveyor 4 is equipped with a photoelectric switch at the working area of the manipulator 1. When the material tray 3 triggers the photoelectric switch, the conveyor belt stops. When the workpiece assembly of a process is completed, the material tray 3 is transferred to the next station.

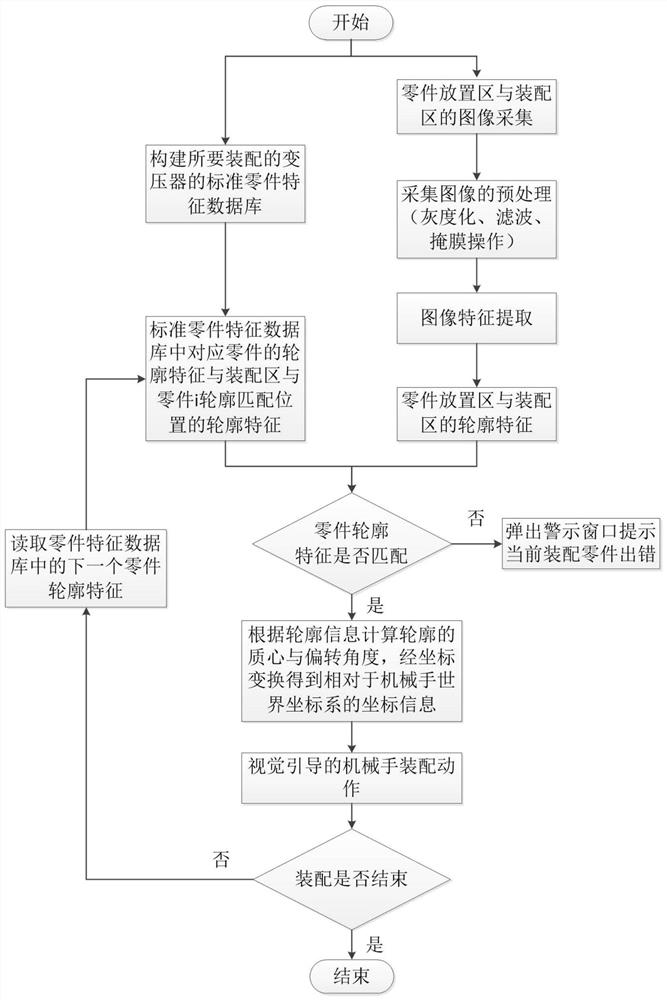

[0020] combine figure 2 , a machine vision-based automatic assembly method for transformers, including building a standard part feature database and assembly of transformers to be assembled.

[0021] The data stored in the standard part fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com