Full-automatic kit assembler

A fully automatic, assembling machine technology, applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of troublesome assembly, low production efficiency, difficult to achieve fully automatic assembly of kits, etc., to improve production efficiency and compact structure. , The effect of fast and effective automatic assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

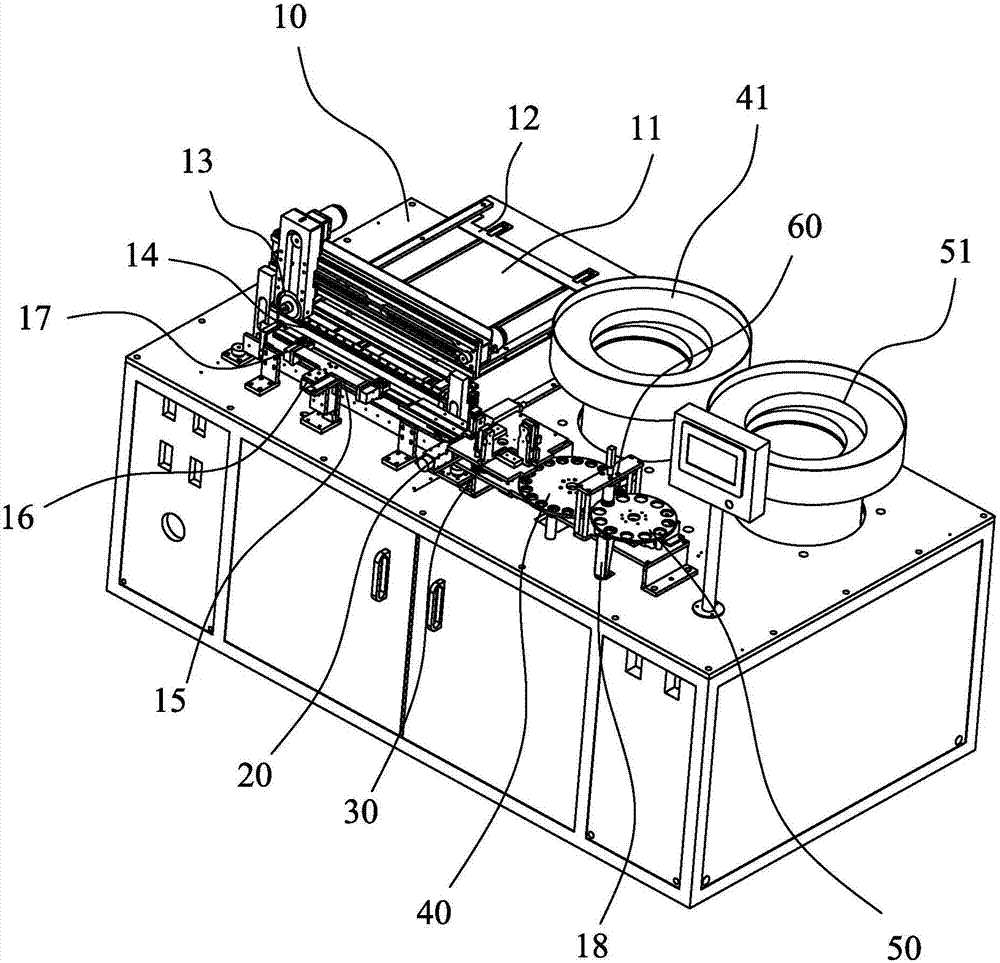

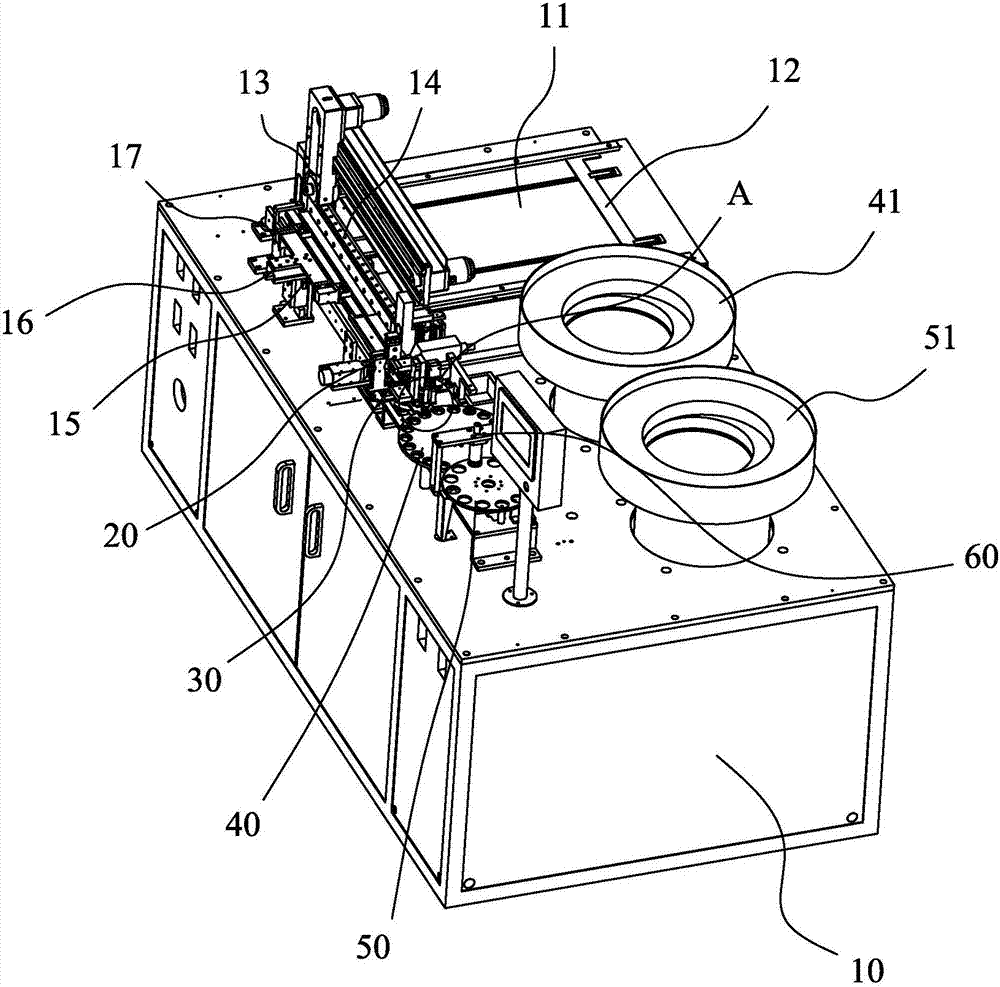

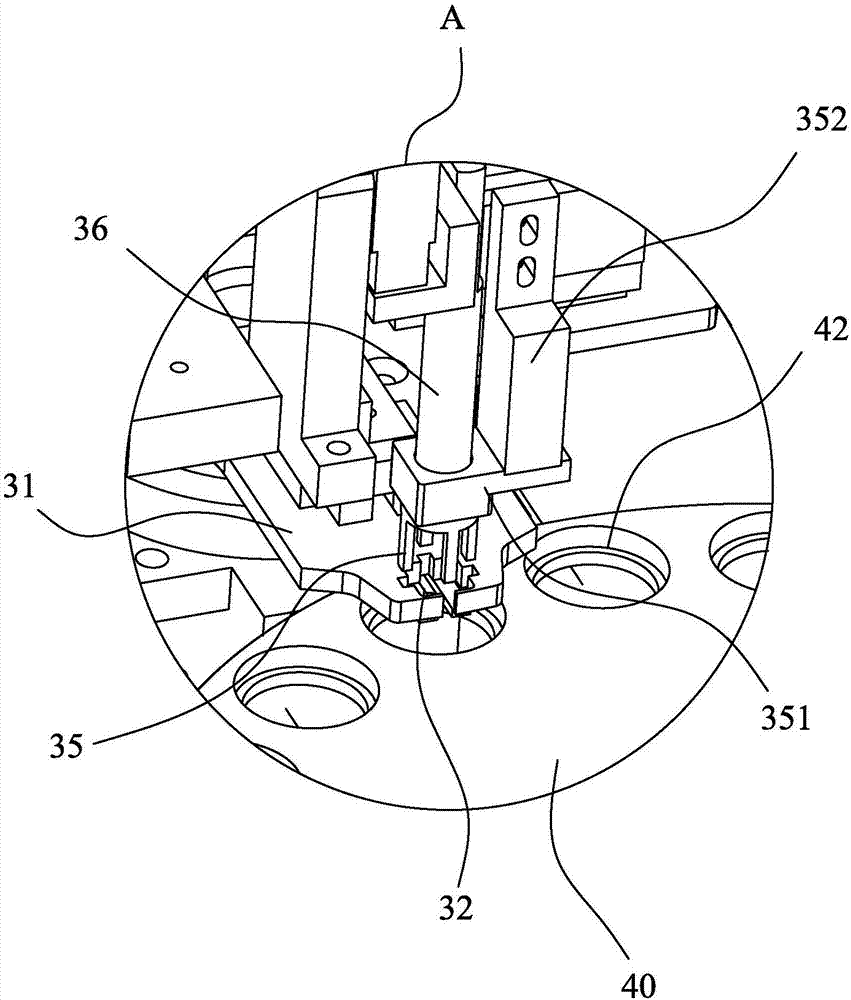

[0026] Example: such as Figure 1-8 As shown, a fully automatic kit assembly machine includes a frame 10, a film plate cutting mechanism, a film strip feeding mechanism, a lower shell vibrating plate 41, an upper shell vibrating plate 51, a film strip cutting mechanism, and a film piece feeding mechanism 30. The lower shell turntable 41, the upper shell turntable 51 and the shell pressing mechanism 60, the membrane plate cutting mechanism is fixedly installed on the frame 10, and the membrane strip feeding mechanism is installed at the port of the membrane plate cutting mechanism, so One side of the film strip feeding mechanism is provided with a film strip cutting mechanism, and one side of the film strip cutting mechanism is connected with a film block feeding mechanism 30, and a lower shell turntable is installed on one side of the film block feeding mechanism 30. 41. An upper shell turntable 51 is installed in rotation on one side of the lower shell turntable 41, and a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com