Slipper strap automatic pad printing system and method

A slipper and pad printing technology, applied in footwear, shoemaking machinery, clothing, etc., can solve labor shortage and other problems, achieve the effect of solving labor shortage, reducing work risk factor, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

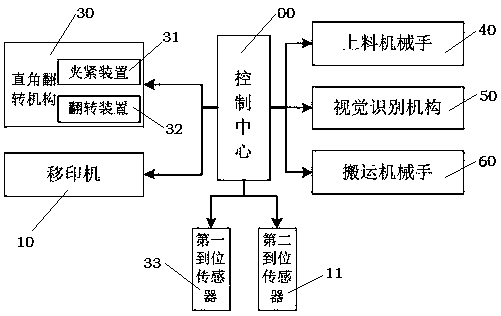

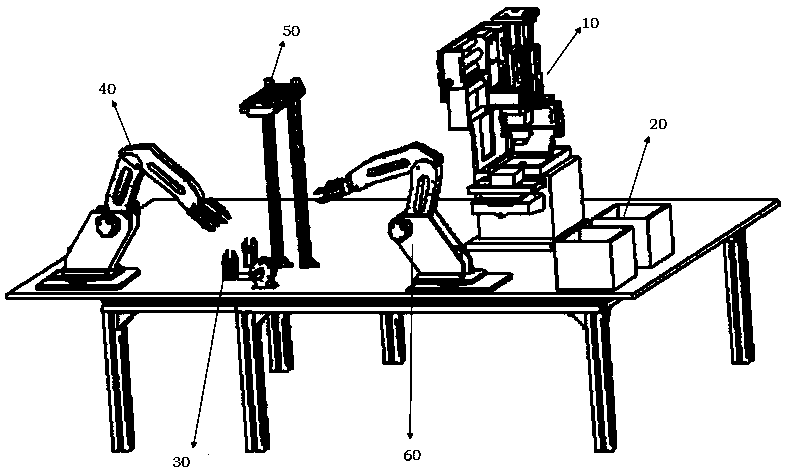

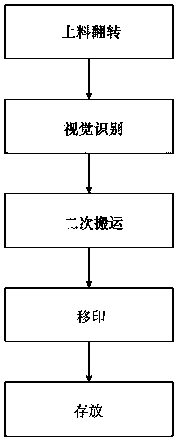

[0024] Such as Figure 1-2 As shown, an automatic pad printing system for slippers includes a pad printing machine 10 and a storage box 20, the pad printing machine 10 is connected to a control center 00, and the control center 00 is also connected to a

[0025] The feeding manipulator 40 is used to grab the slipper straps to be printed in the vertical state and transport them to the

[0026] The right-angle turning mechanism 30 includes a clamping device 31 for clamping the slippers in the vertical state, and a turning device 32 for driving the clamping device 31 to rotate, and the turning device 32 drives the clamping device 31 to drive the slippers to turn over to a horizontal state; The tightening device 31 and the turning device 32 are respectively connected with the control center 00;

[0027] The vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com