Multifunctional food 3D printer

A 3D printer, multi-functional food technology, applied in food forming, food coating, food science and other directions, can solve the problems of large machine size, high cost, poor equipment versatility, etc., to achieve function expansion, comprehensive functions, and satisfaction The effect of multiple taste requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

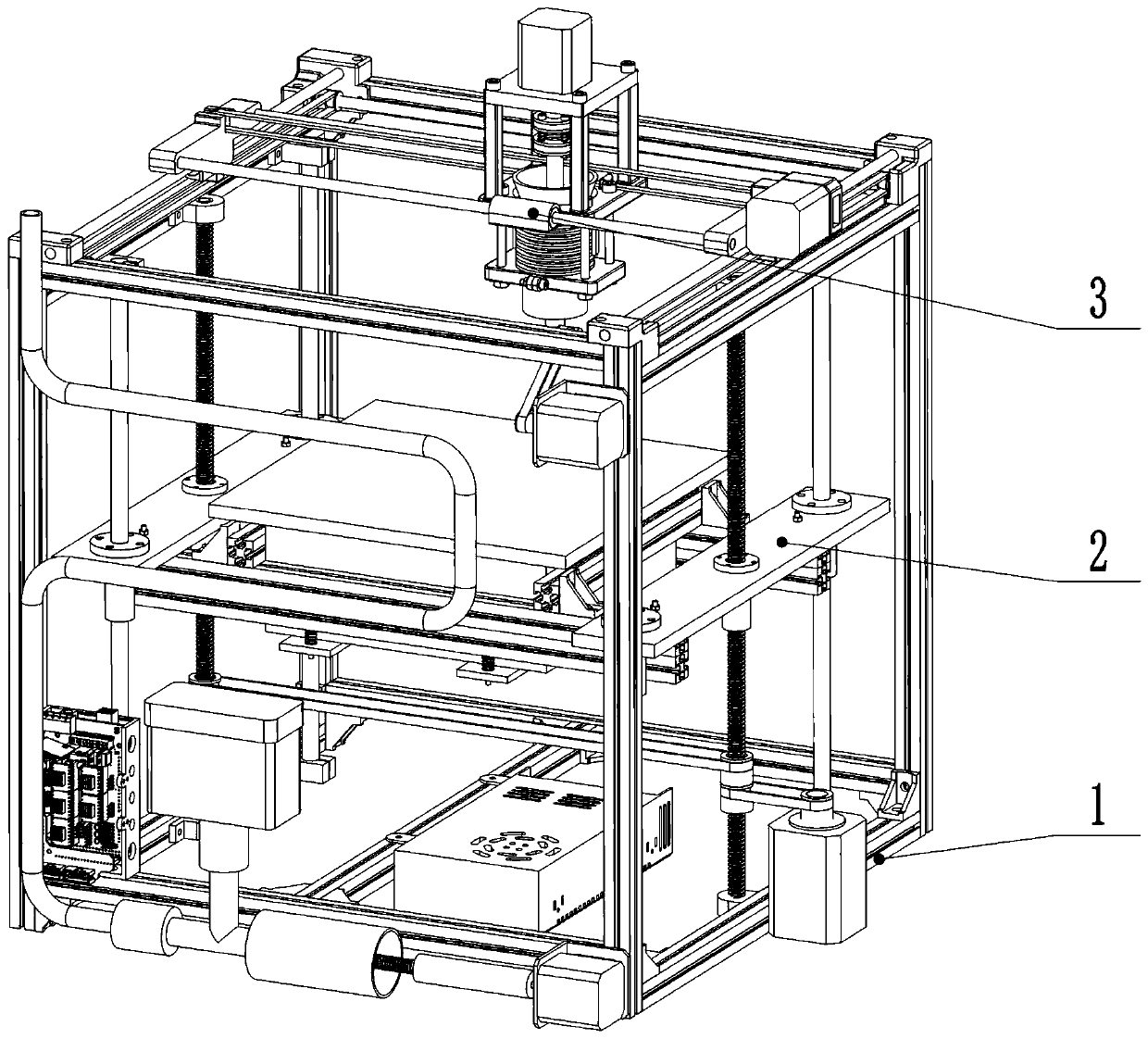

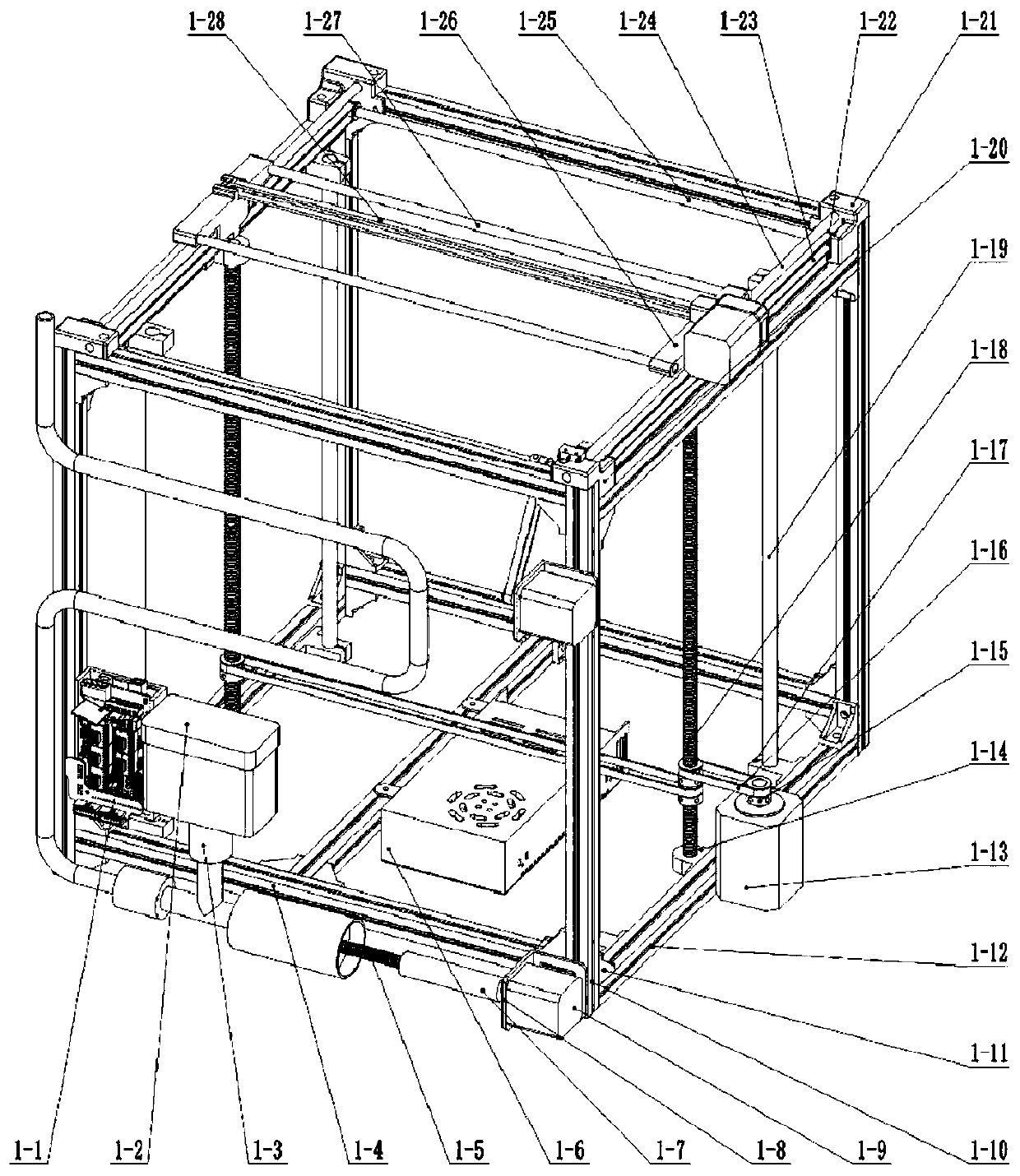

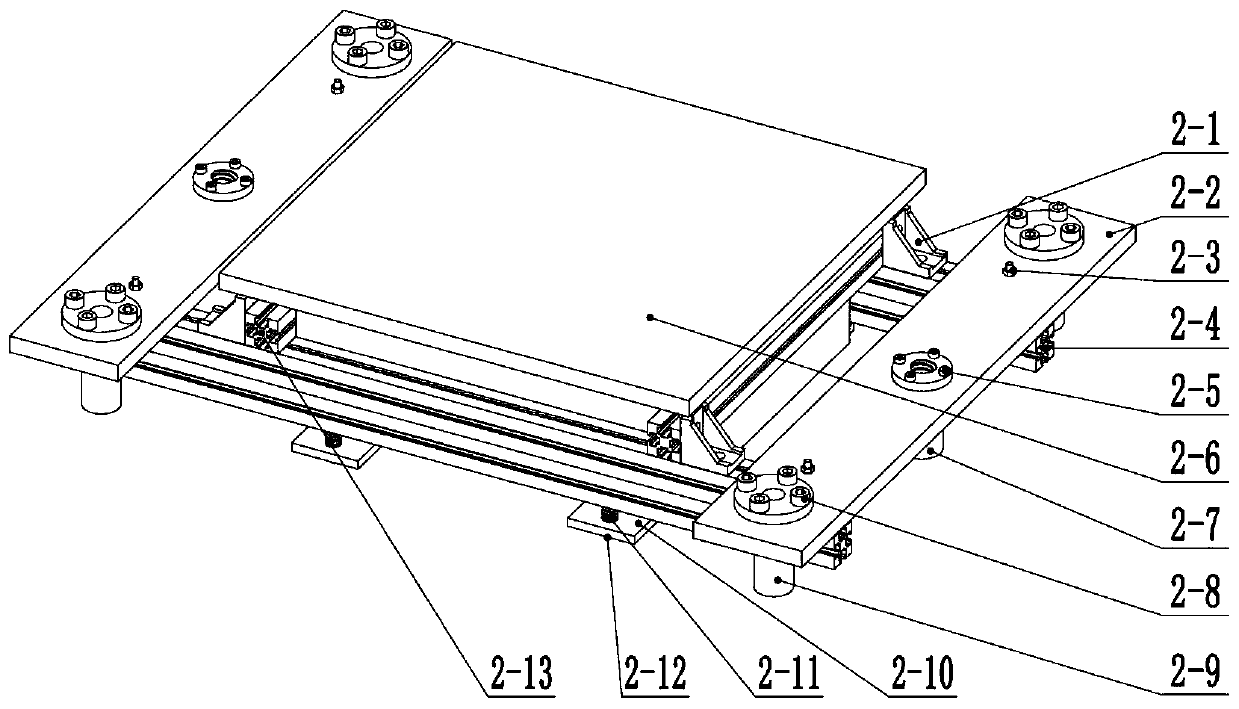

[0056] combine Figure 1 to Figure 4 As shown, a multifunctional food 3D printer, the outer frame 1 includes a three-dimensional box structure composed of 4 X-axis profiles 1-4, 4 Y-axis profiles 1-12, and 4 Z-axis profiles 1-10. The profiles are fixedly connected by angle iron II. A power supply 1-6 is installed under the outer frame 1, and the power supply 1-6 is used to provide voltage to the entire device. A Z-axis guided movement mechanism, an X-axis guided movement mechanism and a Y-axis guided movement mechanism are installed on the outer frame 1 . The heated bed structure 2 is installed on the Z-axis guiding movement mechanism, and the heated bed structure 2 is driven by the Z-axis guiding movement mechanism to realize the movement of the heated bed structure 2 in the Z axis. The X-axis guided movement mechanism is installed on the Y-axis guided movement mechanism, and the X-axis guided movement mechanism is driven by the Y-axis guided movement mechanism to realize t...

Embodiment 2

[0080] The controller 1-1 is installed on the side of the outer frame 1, which is used to control each stepping motor, heating rod, and refrigerator; the controller 1-1 includes a WiFi / Bluetooth module, which can ensure that it is not affected by the network. In this case, the normal input of the model from the mobile terminal can be realized, and the printing efficiency can be improved. The controller is added and programmed with additional modules such as: continuous printing after power failure; detection of material failure; power failure after printing; fault alarm; overload power failure and other functions to ensure the safety of the printer and improve the printing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com