A method for recycling waste refractory materials during the preparation of ternary cathode materials

A technology of discarded refractory materials and positive electrode materials, which is applied in the field of solid waste recycling and treatment in the new energy industry, can solve the problems of no comprehensive utilization of discarded saggers and difficulty in recycling, achieve good industrial application prospects, reduce raw material consumption, and raw material costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

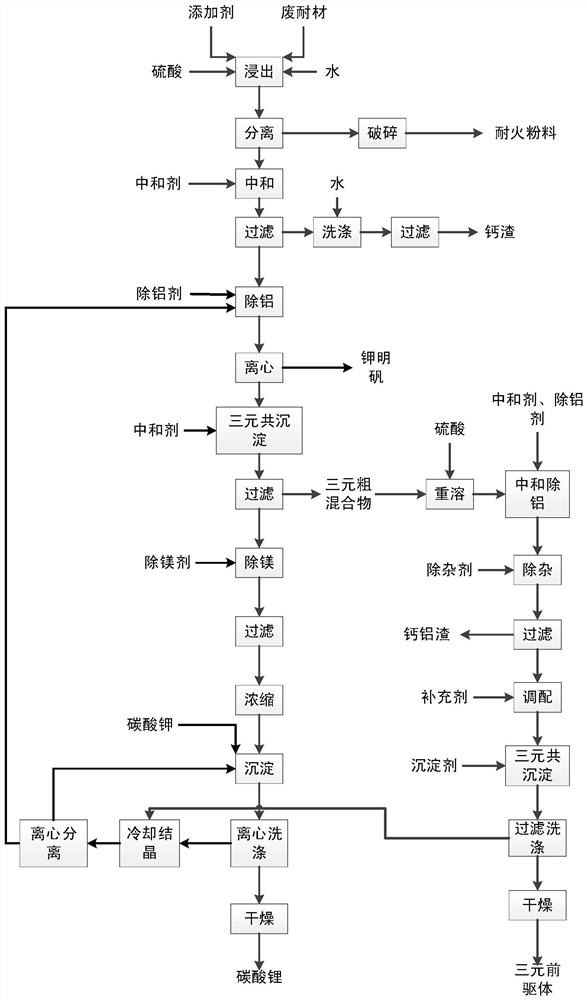

Image

Examples

Embodiment 1

[0118] This embodiment provides a method for recycling waste refractory materials during the preparation of ternary cathode materials. The specific method is as follows:

[0119] (1) Immerse the abandoned sagger described in Table 1 in the leaching tank of 10L sulfuric acid with a molar concentration of 2mol / L for reaction, add 300mL of hydrogen peroxide and carry out normal temperature leaching reaction, take out the sagger after leaching for 10h, and purify the sagger Soak in clean water, soak for 5 hours, rinse with clean water, and then use the sagger for crushing and screening to prepare refractory materials (refractory powder).

[0120] (2) After repeated leaching of 10 discarded saggers, the leaching solution is first separated by filtration, and the filter residue is returned to the leaching tank for deep leaching. After washing, it is discharged as solid waste, and the filtered filtrate is neutralized by adding calcium hydroxide (neutralizing agent) , control the pH e...

Embodiment 2

[0134] This embodiment provides a method for recycling waste refractory materials during the preparation of ternary cathode materials. The specific method is as follows:

[0135] (1) The waste sagger used in Example 1 is immersed in a leaching tank of 20L sulfuric acid with a molar concentration of 3mol / L for reaction, and 800mL of hydrogen peroxide is added for leaching reaction, after leaching for 8h, the sagger is taken out, and the purified sagger The bowl was soaked in clean water, soaked for 4 hours, rinsed with clean water, and the sagger was used for crushing and screening to prepare mullite cordierite composite ceramic raw materials.

[0136] (2) After repeated leaching of 22 discarded saggers, the leaching solution was first separated by filtration, and the filter residue was returned to the leaching tank for deep leaching. After washing, it was discharged as solid waste. The filtered filtrate was neutralized by adding calcium hydroxide, and the pH was controlled at a...

Embodiment 3

[0146] This embodiment provides a method for recycling waste refractory materials during the preparation of ternary cathode materials. The specific method is as follows:

[0147] (1) The waste sagger used in Example 1 is immersed in a leaching tank of 10L sulfuric acid with a molar concentration of 2.5mol / L for reaction, adding 600mL of hydrogen peroxide for leaching reaction, taking out the sagger after leaching for 6h, and purifying The sagger was soaked in clean water, soaked for 4 hours, rinsed with clean water, and then used for crushing and screening to prepare mullite cordierite composite ceramic raw materials.

[0148] (2) After repeated leaching of 20 discarded saggers, the leaching liquid is first separated by filtration, and the filter residue is returned to the leaching tank for deep leaching. After washing, it is discharged as solid waste. The filtered filtrate is neutralized by adding calcium carbonate, and the pH is controlled at an end point of 2.5. , reacted f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com