Battery box, battery box assembly and electric vehicle

A battery box and battery technology, applied in battery pack components, electrical components, circuits, etc., can solve the problems of difficult to guarantee protection requirements, increase production costs, and prolong production cycles, so as to reduce the risk of water seepage, reduce production costs, and reduce production costs. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

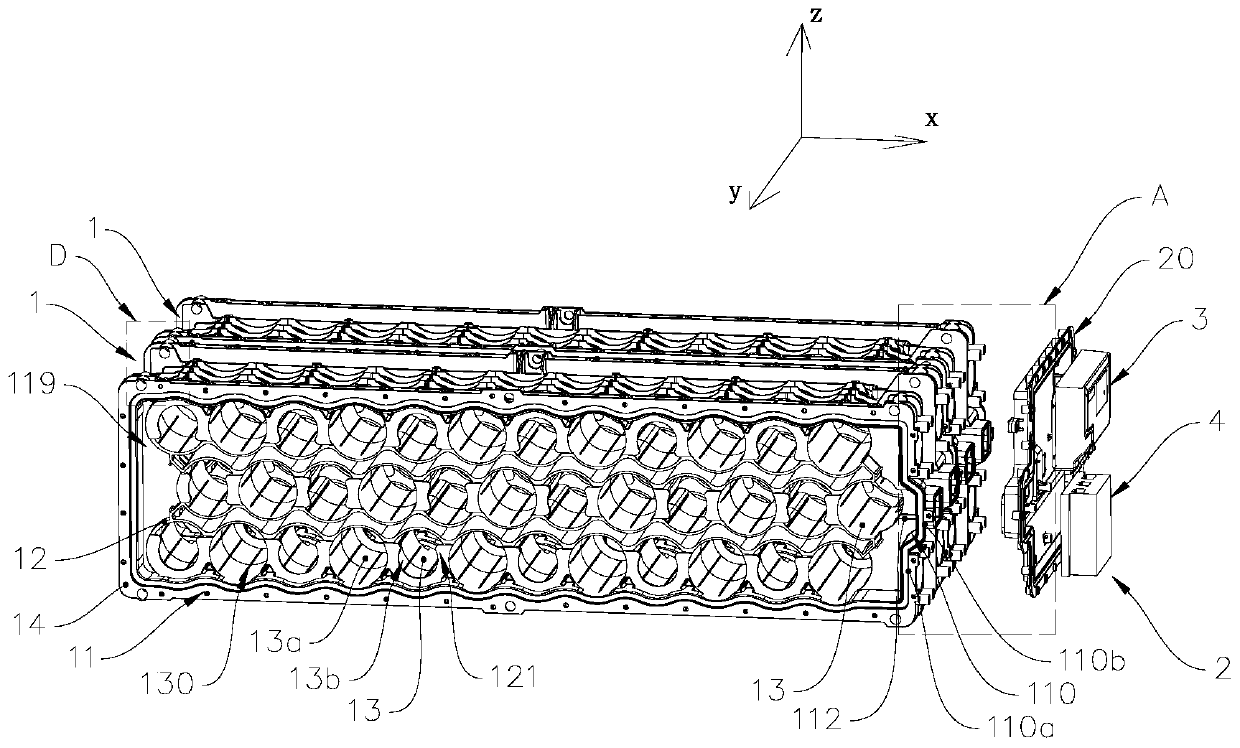

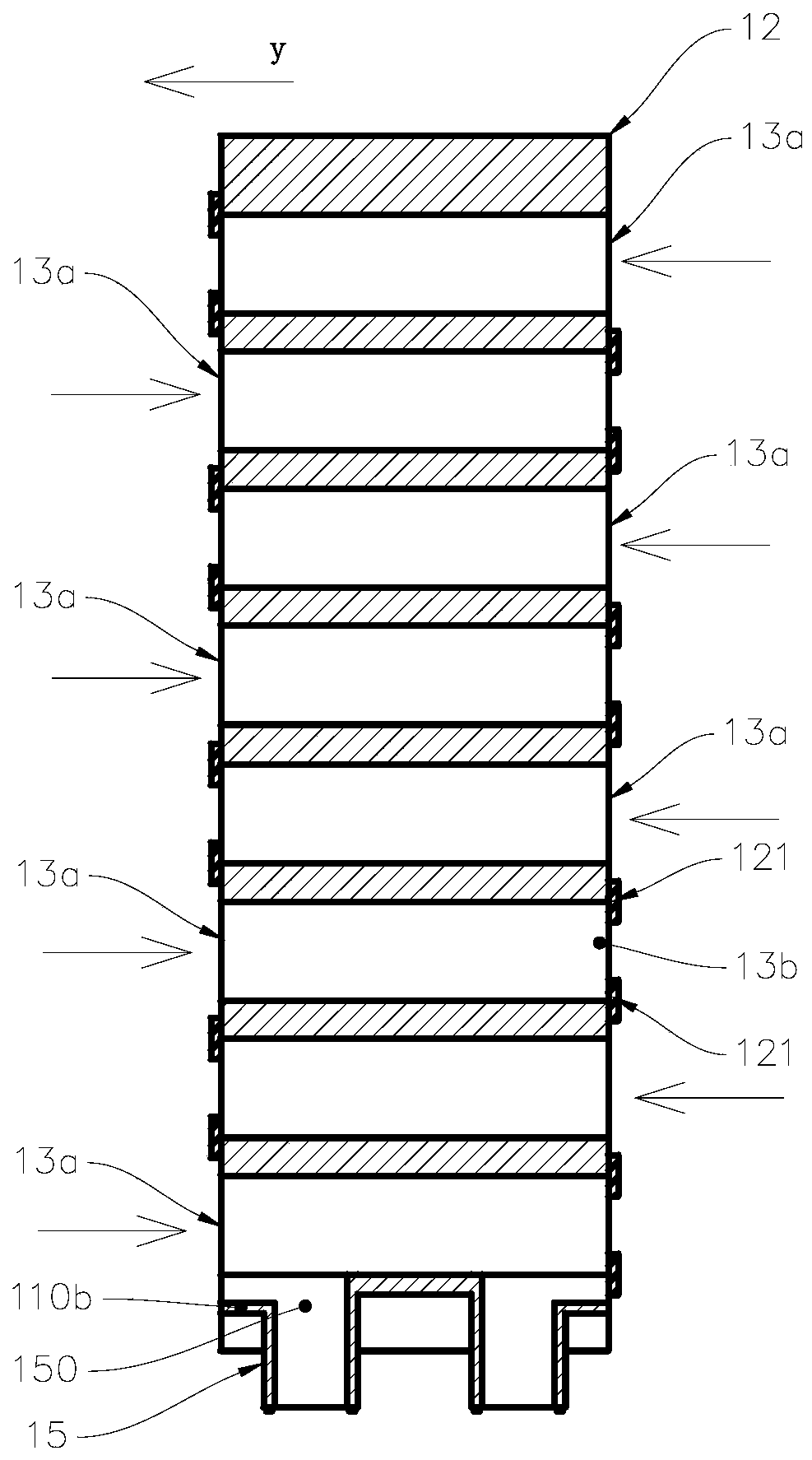

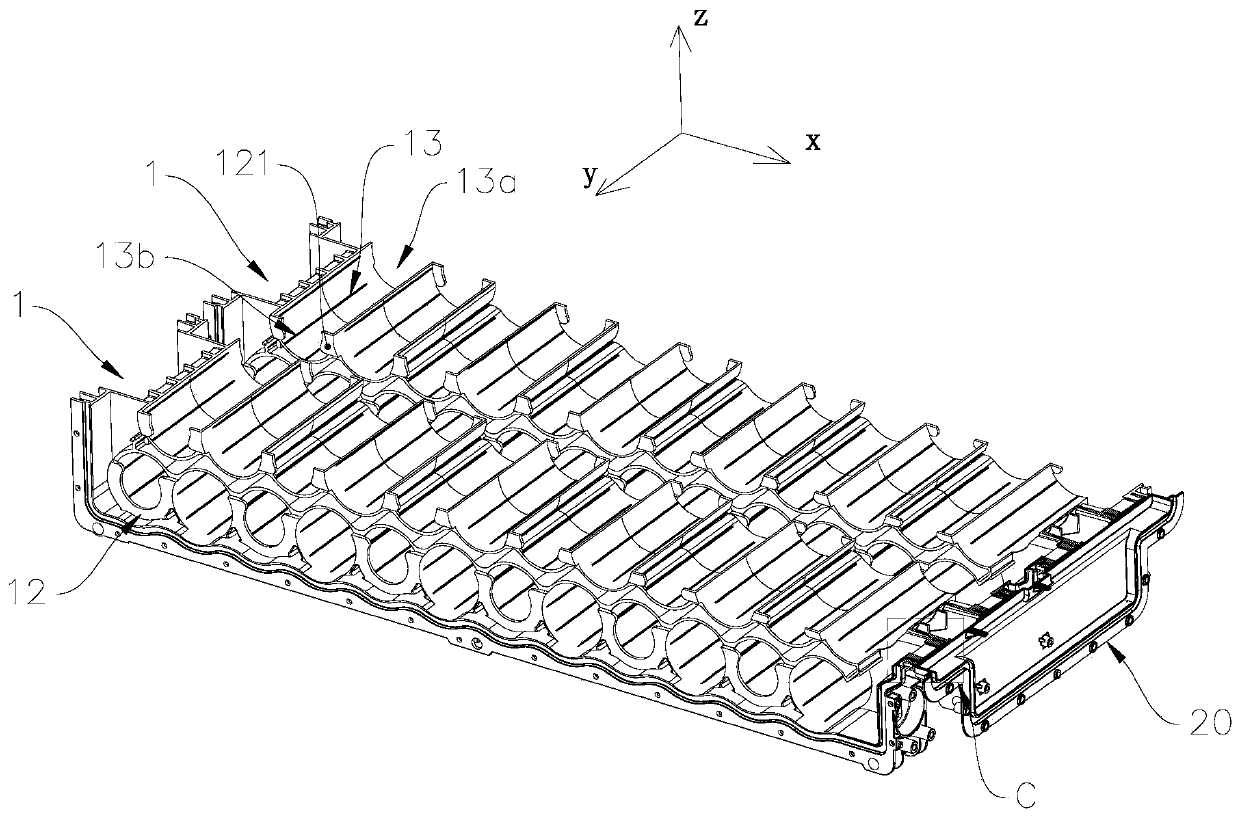

[0051] see figure 1 , figure 1 It is an exploded view of the structure of the embodiment of the battery box assembly of the present invention. There is a battery box assembly in the electric vehicle. The battery box assembly includes two battery boxes 1 and a controller box 2 arranged side by side. The battery box 1 is an integrally formed piece of insulating material, and the controller box 2 includes a controller box base that is covered with each other. 20 and the controller box cover (not shown), the controller box base 20 and the controller box cover form a space for placing the controller, and the controller placed in the controller box 2 includes a BMS battery management System 3 and BMS battery management system 4, wherein BMS battery management system 3 has 12 serial ports, and BMS battery management system 4 has 24 serial ports. The control box base 20 is directly locked and connected to the battery box 1, the wire hole on the control box base 20 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com