Power station equipment maintenance welding operation process control method

A technology of process control and equipment, applied in the direction of manufacturing computing systems, instruments, data processing applications, etc., can solve the problems of untimely information transmission in the operation stage, unclear stage definition, lagging or wrong information communication of equipment maintenance personnel, etc., to achieve improvement Welding operation efficiency, welding operation process is clear and clear, and the effect of improving the quality of welding implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

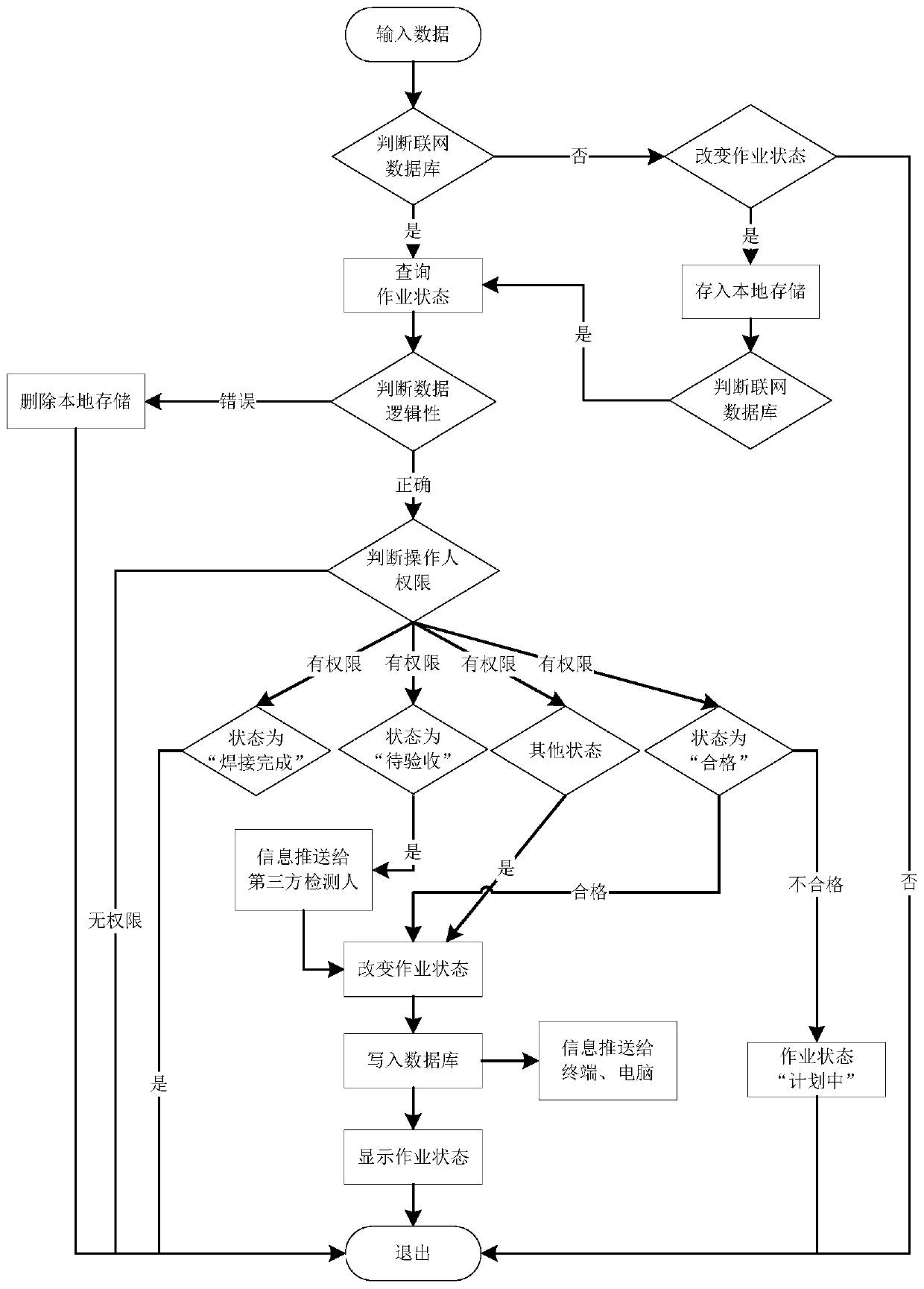

[0019] Such as figure 1 As shown, a method for controlling the welding operation process of power station equipment maintenance provided by the present invention, the method specifically includes the following steps:

[0020] Step (1) Scan the barcode through the terminal or computer to obtain the welding operation status data information of the power station equipment, and perform data input; the specific steps of step (1) are as follows:

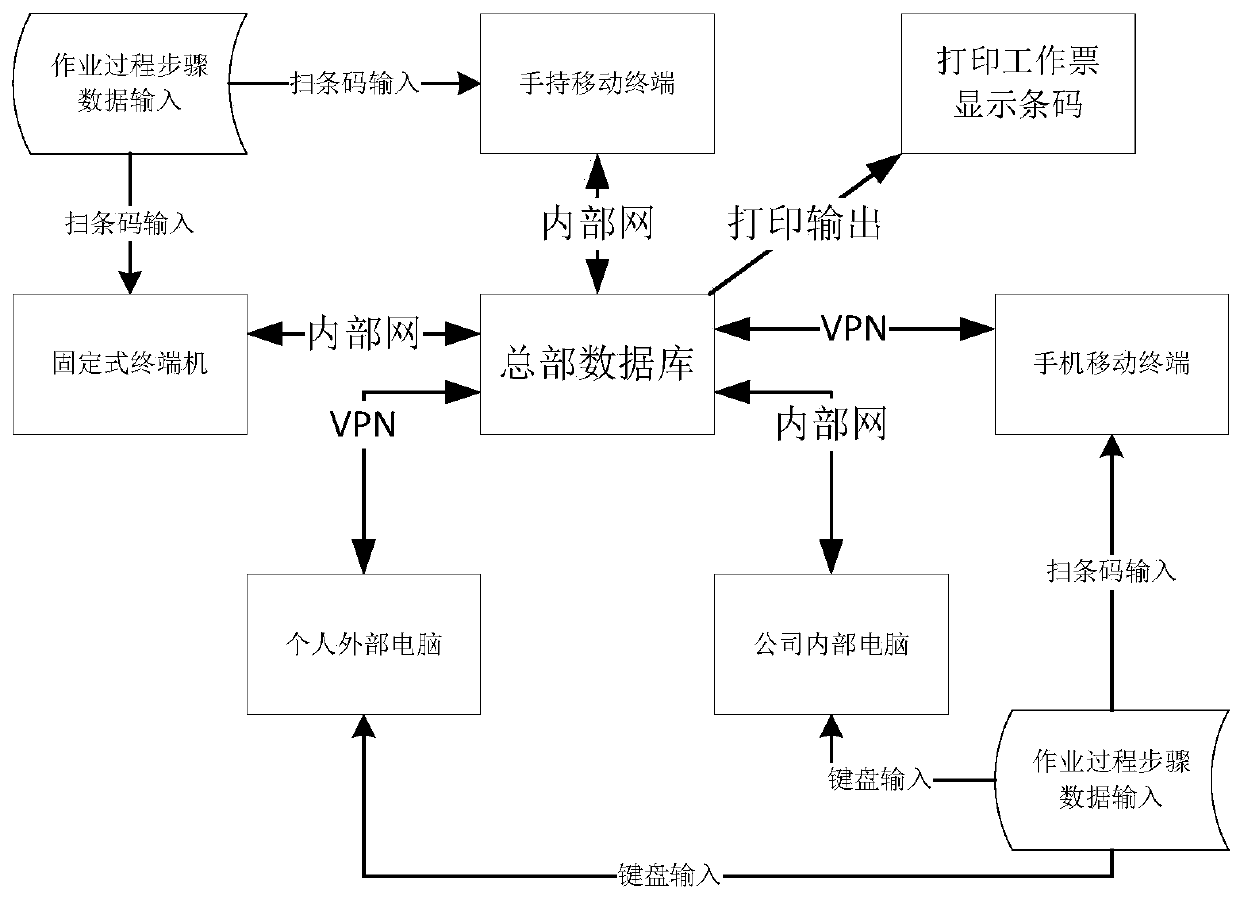

[0021] Such as figure 2 As shown, the step (1.1) sets up the headquarters database, which is used to save the welding operation status data information of the power station equipment.

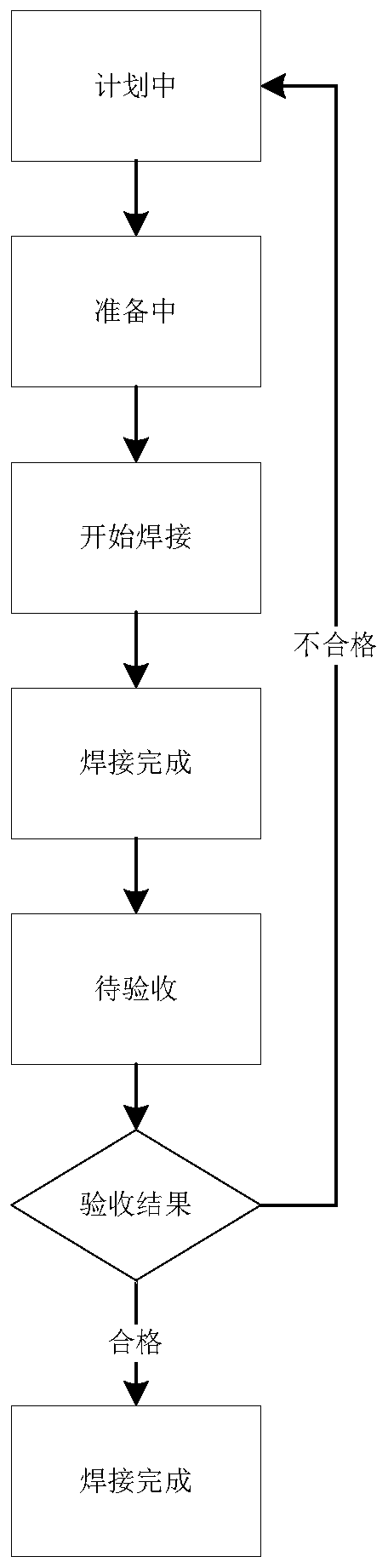

[0022] Such as image 3 As shown, the power station equipment welding operation status data information includes seven items: planning, preparation, welding start, welding completion, pending acceptance, acceptance resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com