Construction method of hoisting steel truss arch members by using high and low pole beams through the narrow opening

A technology of shoulder pole beams and rods, which is applied in the construction field of hoisting steel truss arch rods through narrow closing dragon mouths by using high and low shoulder pole beams. problem, to avoid spreader collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

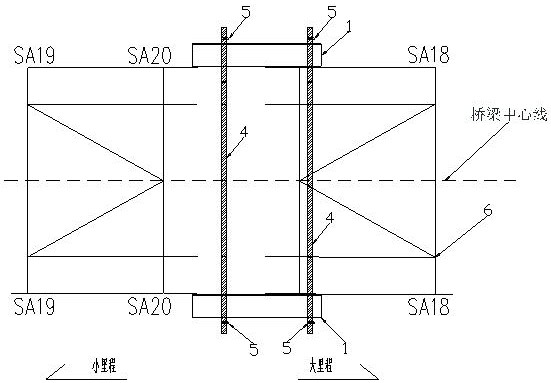

[0025] see Figure 1 to Figure 4 , a construction method for hoisting steel truss arch members through a narrow closing mouth by using high and low pole beams, according to the following steps:

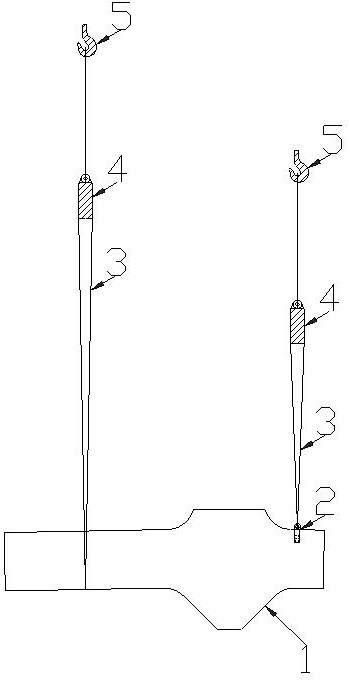

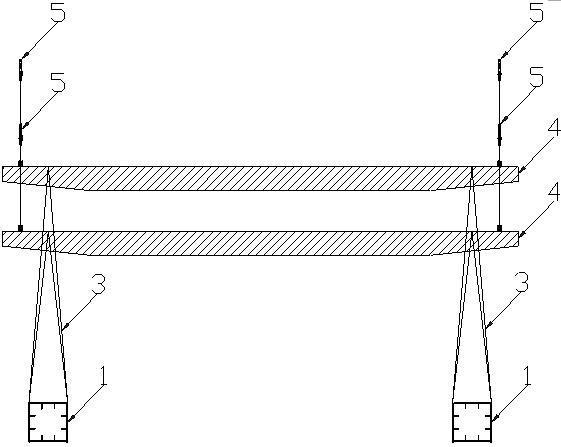

[0026] (1) Set two lifting points and lifting lugs 2 on the two rods 1 on both upstream and downstream sides, connect the lifting points 2 with a 50t sling 3, and connect the other end of the sling 3 to the pole beam 4;

[0027] (2) By controlling the length of the sling 3, the length of the sling 3 on the small mileage side is greater than the length of the sling 3 on the large mileage side. On the pole beam 4 on the mileage side;

[0028] (3) The pole beam 4 with a small mileage is connected to the main hook 5 of the cable crane with a small mileage, and the pole beam 4 on the side with a large mileage is connected to the main hook 5 with a large mileage,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com