Jacking construction method for prefabricated frame with inversely arranged oil top on variable ramp

A construction method and technology of oil top, applied in the direction of road bottom layer, building, etc., can solve problems such as slideway damage, frame structure damage, slideway structure damage, etc., and achieve good operation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing.

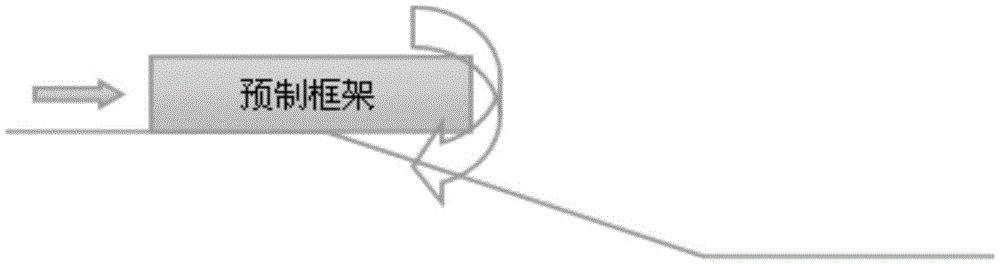

[0048] see Figure 11 Put the oil top 2 on one end of the prefabricated frame 4, the back seat of the oil top 2 is placed against the prefabricated frame 4, the piston rod of the oil top 2 is connected with the force transmission rod 3 and placed on the back 1, through the oil The jack 2 applies a jacking force to the back 1, and according to the principle of action force and reaction force, the rear seat of the oil jack 2 pushes the prefabricated frame 4 to move forward.

[0049] according to Figure 11 It shows that the application of the oil top inversion technology on the variable slope slideway needs to solve the following problems:

[0050] ①The jacking stroke of the prefabricated frame 4 reaches 60m, and the force transmission rod 3 is in an inclined state, which may cause the force transmission rod 3 to lose stability during the jacking process; the vertical plane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com